High-frequency filter applied to grid-connected inverter

A high-frequency filter and inverter technology, applied in the direction of single-network parallel feed arrangement, output power conversion device, electrical components, etc., can solve the problems of high-frequency current component increase, damping resistor burnout, etc., and achieve strong damping characteristics, the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

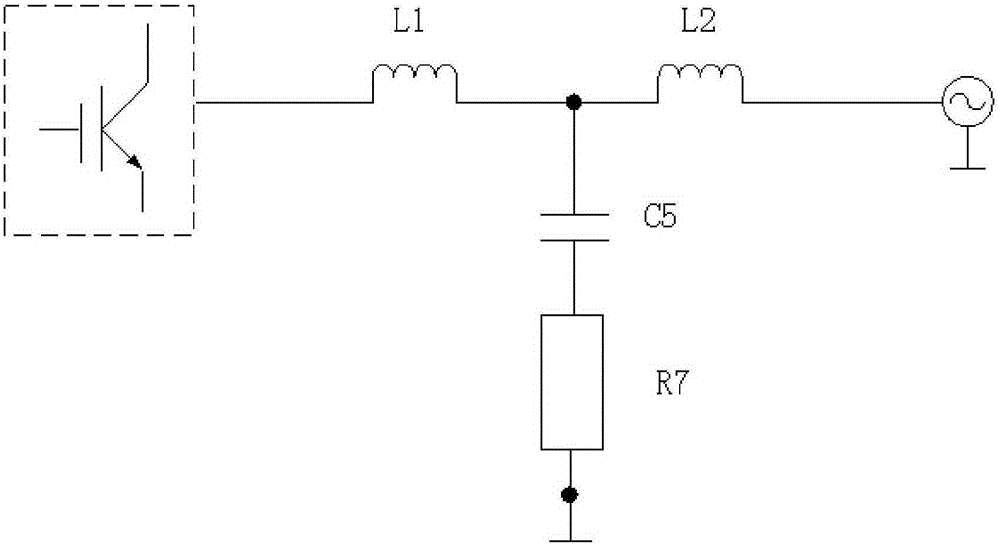

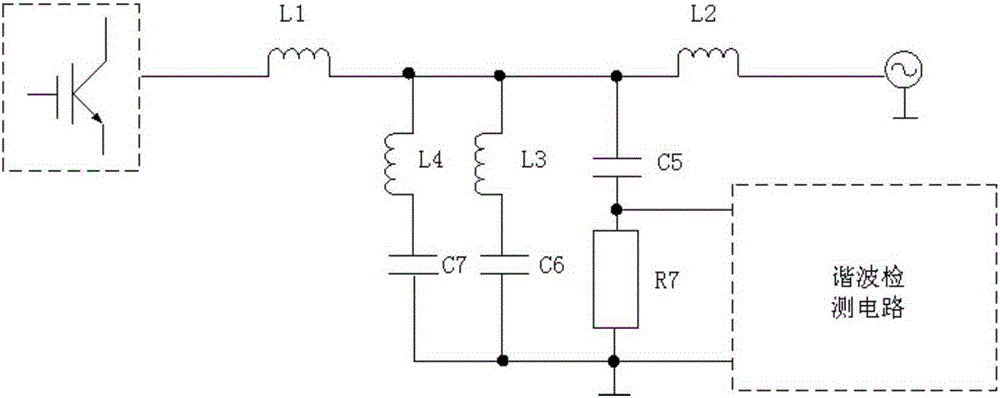

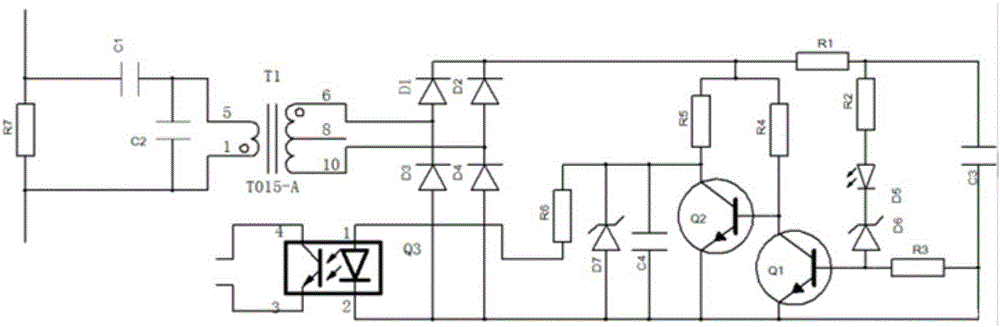

[0016] figure 1 It is the schematic diagram of the traditional LCL filter circuit. The output of the IGBT converter is connected to the inductor L1, and the output end is connected to the power grid through the inductor L2. The high-frequency components output by the IGBT bridge side are mainly bypassed to the neutral line through the RC damping branch, because The average effective value of the high-frequency component of the current is generally 10-30A, which will cause a very large loss in the damping resistor. If you want to reduce the loss, you can only make the resistance value smaller, but this will weaken the damping effect and make the system It is easier to fall into a resonance state. Therefore, the traditional LCL filter is contradictory between power consumption and stability. This problem can be improved by using the active dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com