Method used for shielding vacuum electron beam welding machine magnetic field

A vacuum electron beam welding and magnetic field technology, applied in electron beam welding equipment, magnetic field/electric field shielding, electrical components, etc., can solve problems such as inability to carry out, difficult demagnetization, etc., and achieve the effect of eliminating interference, significant effect, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for shielding the magnetic field of a vacuum electron beam welding machine. When the magnetic induction intensity of some large parts or some mechanical devices in the equipment is greater than the welding requirement, demagnetization becomes very difficult or impossible. The method of the invention can be used on the path of the electron beam. Steps include:

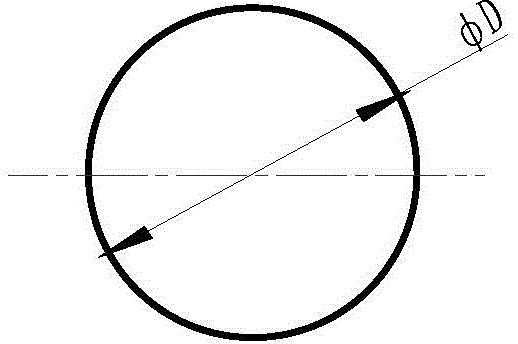

[0019] (1) Measure the outer diameter of the focusing coil of the electron gun.

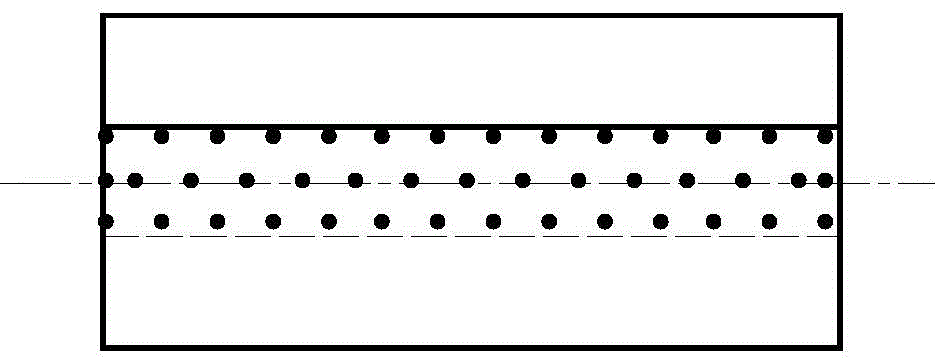

[0020] (2) Roll the foil-shaped stainless steel sheet into a cylindrical shielding cover, the inner diameter of the shielding cover is adapted to the outer diameter of the focusing coil, and the seams of the shielding cover are connected by energy storage spot welding. Shield structure see figure 1 and figure 2 .

[0021] Specifically, the thickness of the foil-shaped stainless steel sheet is 0.3-0.6 mm.

[0022] (3) Use clamps to fix the shield on the outer circumference of the focusing coil. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap