Cluster casting shell mould and technology for cast steel tool aprons of rotary cultivators

A technology of rotary tiller and knife holder, which is applied in the directions of casting mold, mold composition, casting molding equipment, etc. hole, meet the desire for low-price maintenance, and reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

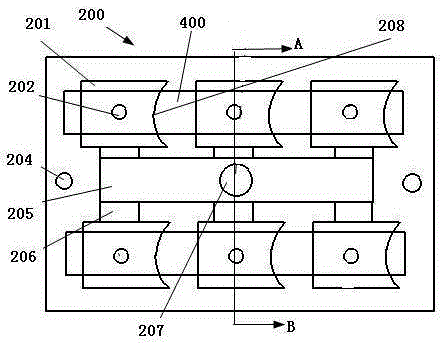

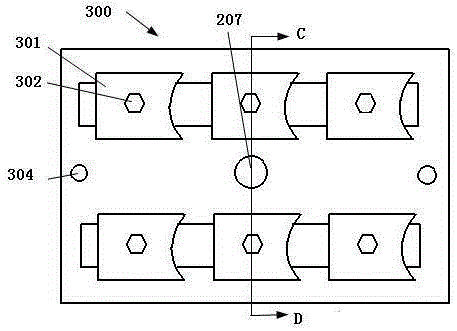

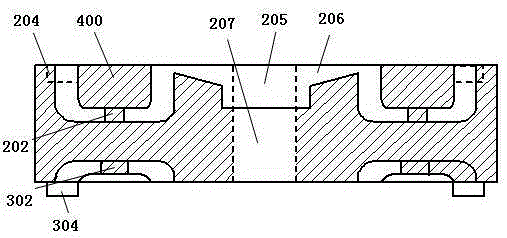

[0027] Refer to the following Figure 1-Figure 8 The technical objection of the present invention is further described in detail.

[0028] The technical solution of the present invention is a cluster cast shell type of cast steel knife seat for rotary tiller, figure 1 is a schematic diagram of the top shell structure, figure 2 It is a schematic diagram of the right-view structure of the upper shell type, image 3 Is the cross-sectional schematic diagram of the intermediate shell. in image 3 , the above structure is figure 1 Schematic diagram of the cross-sectional structure of the A-B plane in the middle, the following is figure 2 Schematic diagram of the cross-sectional structure of plane C-D.

[0029] The tool holder cluster casting shell mold 100 is a multi-layer shell mold. The multi-layer shell mold is made of coated sand. The multi-layer shell mold includes a bottom shell mold, a middle shell mold and a top shell mold. Each of the bottom shell molds A plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com