Lifting and positioning device for vacuum chamber optical components

A technology for optical components and lifting positioning, which is applied in the direction of optical components, optics, optical surface grinders, etc., can solve the problems of prolonging energy, waste, and large repeated positioning errors, and achieves the advantages of convenient use, simple overall structure, and small repeated positioning errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

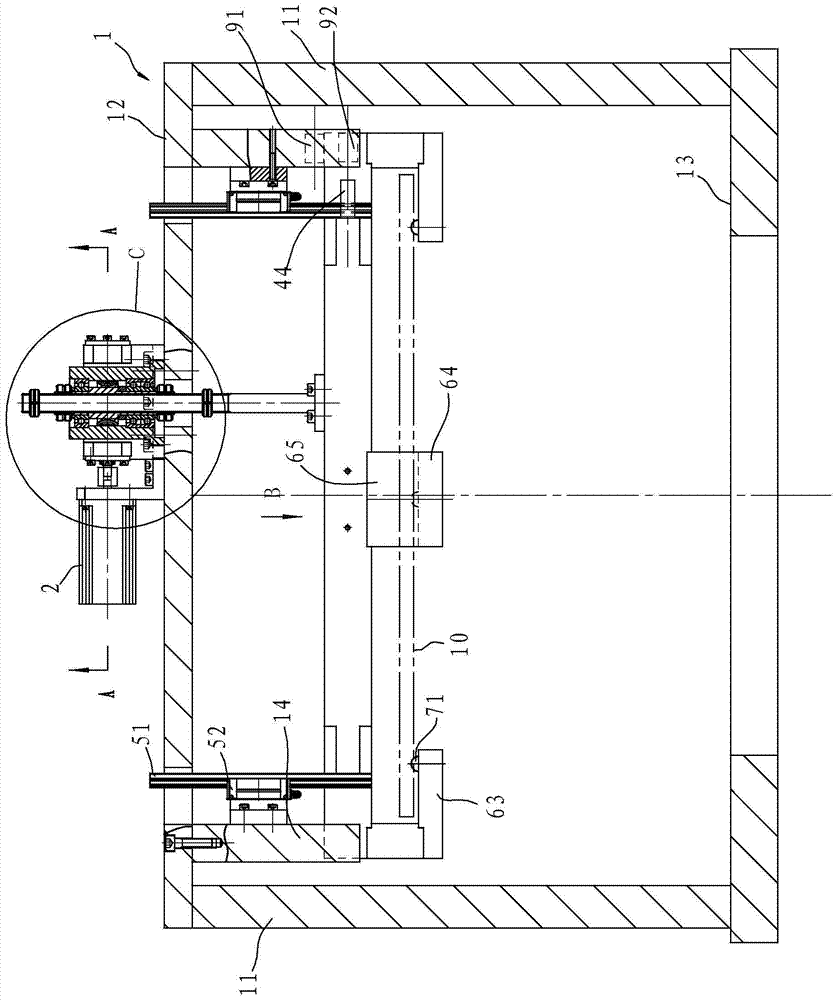

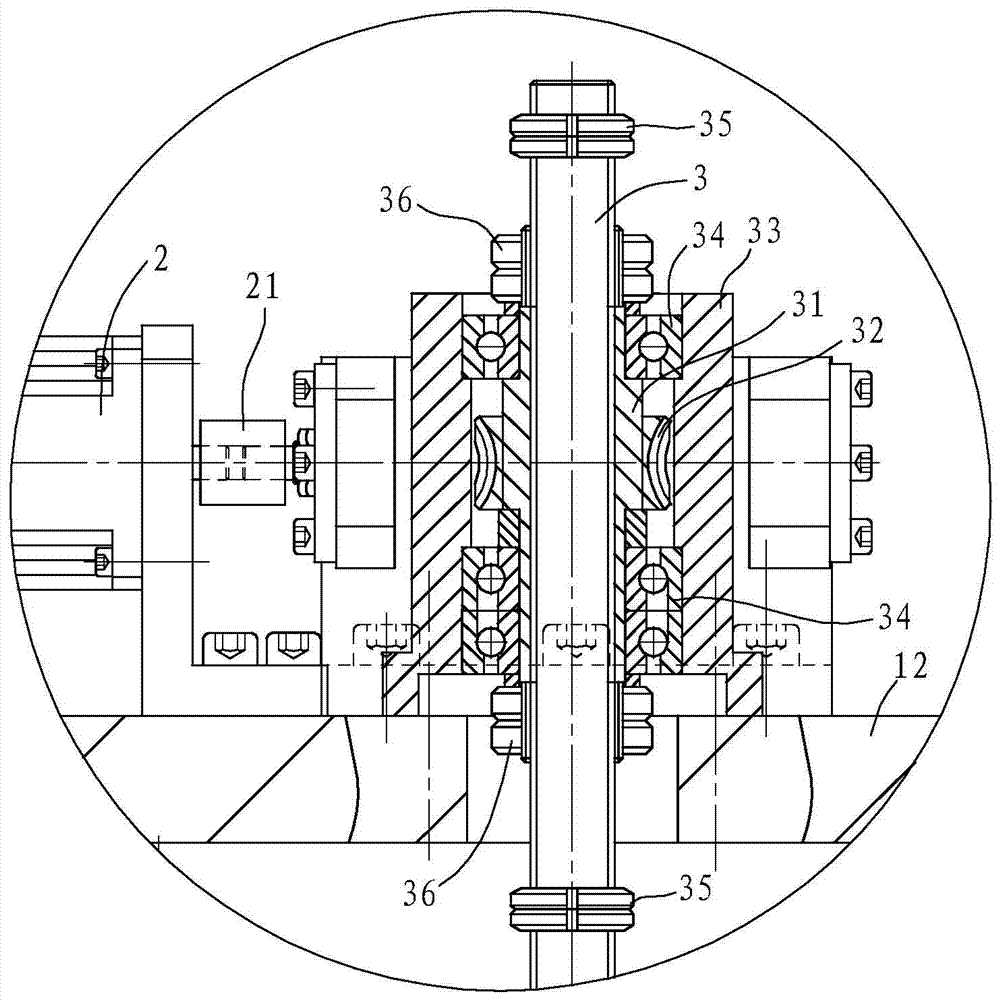

[0032] Such as figure 1 As shown, the vacuum chamber optical element lifting and positioning device in this embodiment includes a frame body 1, a motor 2, a tray 4, a screw rod 3 and a guide mechanism 5, and the frame body 1 includes two vertical plates 11 and is located on the vertical plate 11. Top plate 12, top plate 12 offers the through hole that passes for screw mandrel 3, and top plate 12 lower end face is extended downwards and is provided with connecting plate 14, and for improving fastness, vertical plate 11 bottoms are connected and fixed with base plate.

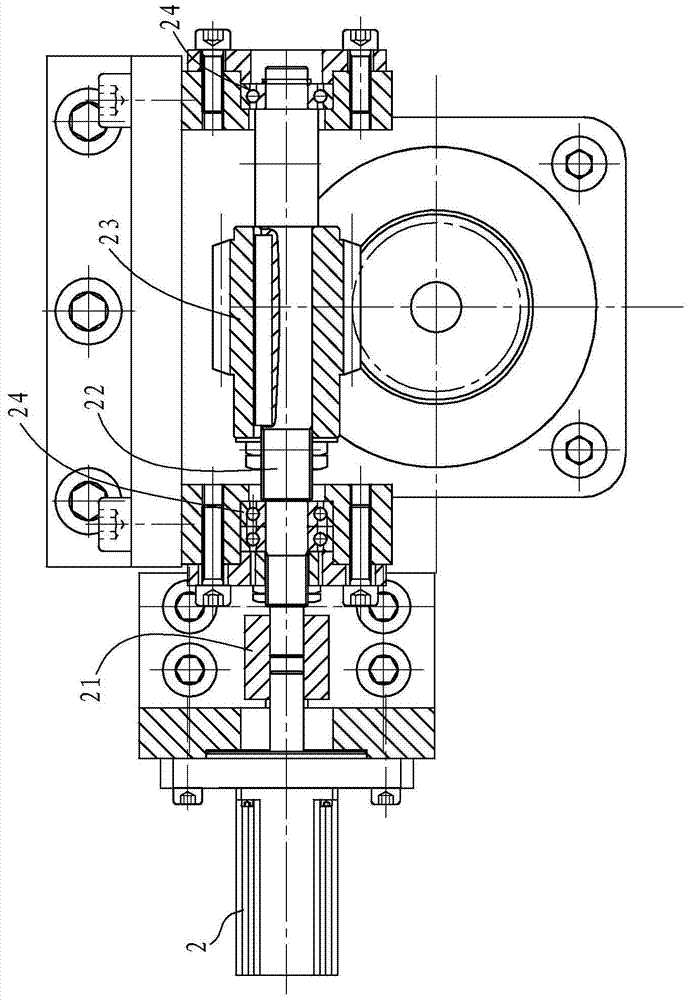

[0033] combine image 3 As shown, the motor 2 is arranged on the top plate 12, and the output end of the motor 2 is provided with a coupling 21, and the coupling 21 is connected with a rotating shaft 22, and the rotating shaft 22 is provided with a synchronously rotating worm sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com