Method for preparing ceramic matrix composite material through SiC nano-wire modified ceramic matrix composite material interface

A composite material and ceramic-based technology, which is applied in the field of preparation of ceramic-based composite materials, can solve problems such as gaps in the research field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

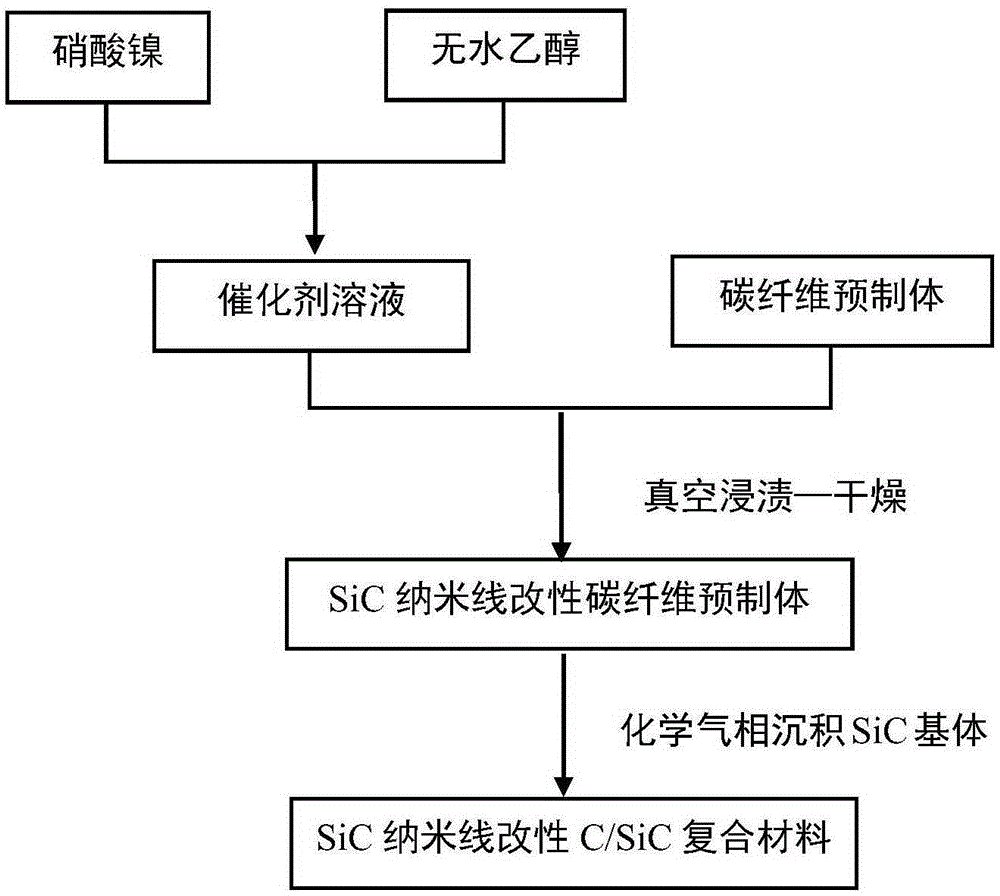

Method used

Image

Examples

Embodiment 1

[0036] 1. The carbon fiber preform was ultrasonically cleaned with absolute ethanol for 30 minutes, and then placed in an oven to dry at 70°C for use.

[0037] 2. Prepare the catalyst solution. Weigh nickel nitrate and anhydrous ethanol to prepare a 0.05mol / L catalyst solution, stir and mix well.

[0038] 3. Vacuum impregnation of the porous carbon fiber preform. Put the porous carbon fiber preform and the catalyst solution into a glass impregnation tank, vacuum -0.10 MPa, vacuum for 5 minutes, 5 minutes later, impregnate the preform into the catalyst solution until the porous carbon fiber preform is completely submerged, and perform vacuum impregnation. After 90 minutes of immersion. Take out the impregnated carbon fiber preform and dry it at a drying temperature of 70°C, and obtain a vacuum impregnated porous carbon fiber preform after drying.

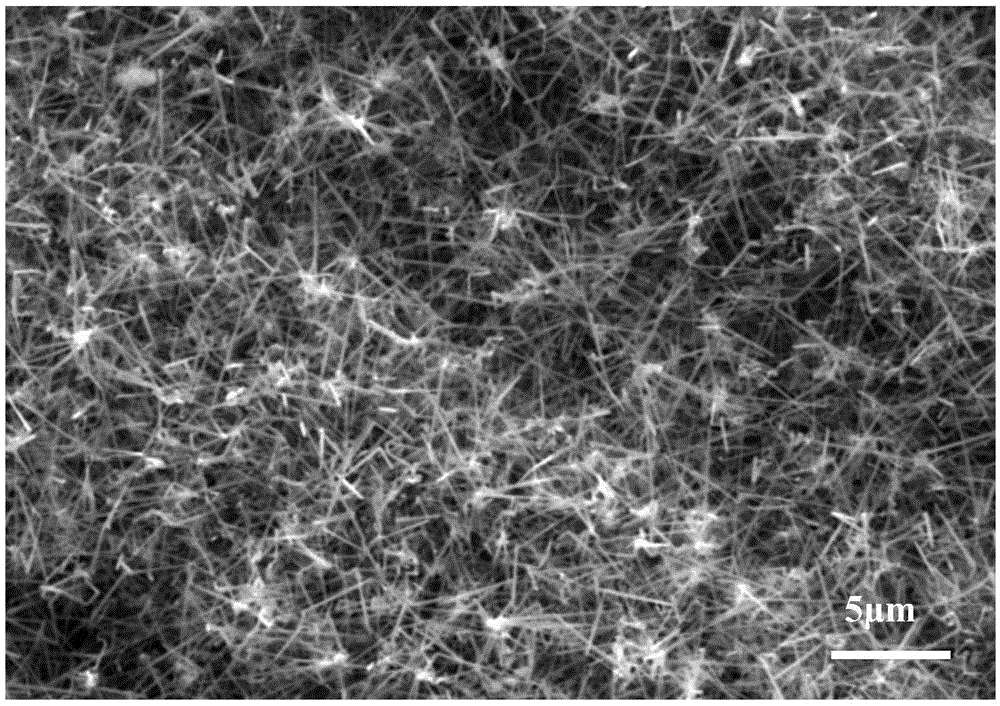

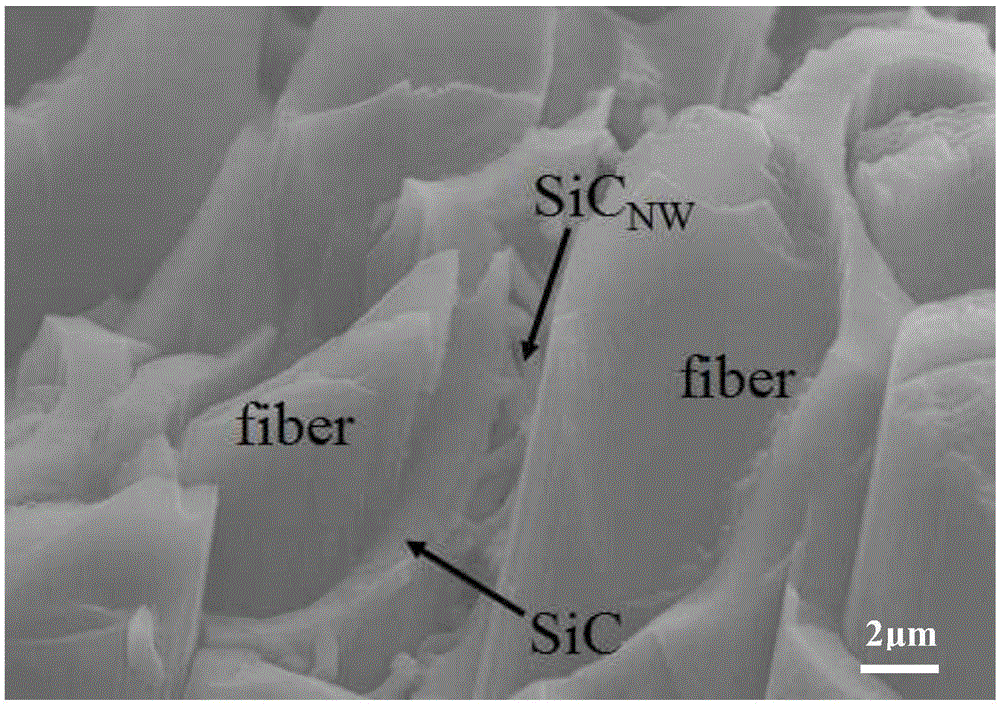

[0039] 4. In-situ deposition of SiC nanowires. The impregnated porous carbon fiber preform is placed in a vertical CVD furnace to depo...

Embodiment 2

[0043] 1. The carbon fiber preform was ultrasonically cleaned with absolute ethanol for 30 minutes, and then placed in an oven to dry at 70°C for use.

[0044] 2. Prepare the catalyst solution. Weigh nickel nitrate and anhydrous ethanol to prepare a 0.05mol / L catalyst solution, stir and mix well.

[0045] 3. Vacuum impregnation of the porous carbon fiber preform. Put the porous carbon fiber preform and the catalyst solution into a glass impregnation tank, vacuum -0.10 MPa, vacuum for 5 minutes, 5 minutes later, impregnate the preform into the catalyst solution until the porous carbon fiber preform is completely submerged, and perform vacuum impregnation. After 90 minutes of immersion. Take out the impregnated carbon fiber preform and dry it at a drying temperature of 70°C, and obtain a vacuum impregnated porous carbon fiber preform after drying.

[0046] 4. In-situ deposition of SiC nanowires. The impregnated porous carbon fiber preform is placed in a vertical chemical vapor depo...

Embodiment 3

[0049] 1. The carbon fiber preform was ultrasonically cleaned with absolute ethanol for 30 minutes, and then placed in an oven to dry at 70°C for use.

[0050] 2. Prepare the catalyst solution. Weigh nickel nitrate and anhydrous ethanol to prepare a 0.05mol / L catalyst solution, stir and mix well.

[0051] 3. Vacuum impregnation of the porous carbon fiber preform. Put the porous carbon fiber preform and the catalyst solution into a glass impregnation tank, vacuum for 5 min to -0.10 MPa, 5 min later, the preform is immersed in the catalyst solution until the porous fiber preform is completely submerged for vacuum impregnation. After 90 minutes of immersion. Take out the impregnated fiber preform and dry it at a drying temperature of 70°C, and obtain a vacuum impregnated porous carbon fiber preform after drying.

[0052] 4. In-situ deposition of SiC nanowires. The impregnated porous carbon fiber preform is placed in a vertical chemical vapor deposition furnace to deposit SiC nanowir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com