Method for preparing silver ion antibacterial fiber

An antibacterial fiber and silver ion technology, applied in the field of textile fibers, can solve the problems of unstable process, poor antibacterial durability of antibacterial fibers, difficult spinning and processing, etc., and achieve the effect of superior washing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

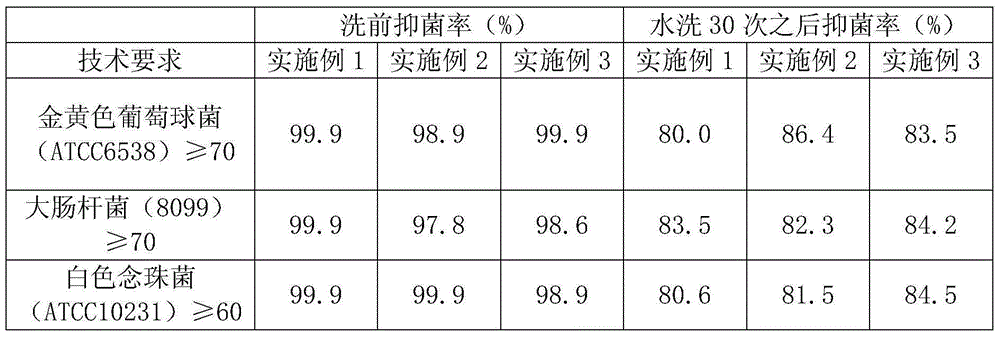

Embodiment 1

[0024] This embodiment discloses a kind of method for preparing silver ion antibacterial fiber, described method comprises the following steps:

[0025] 1) Melt and mix the silver ion powder, silicon-containing surfactant and polyester chips to obtain a functional master batch; the diameter of the silver ion powder is less than 0.4 μm; based on the total mass of the functional master batch, the The mass percentage of the silver ion powder is 16%, and the mass percentage of the silicon-containing surfactant is 4%; the silicon-containing surfactant is hexamethyldisiloxane;

[0026] 2) After mixing the functional masterbatch and polyester chips, add them to a screw extruder for spinning to obtain silver ion antibacterial fibers.

[0027] Specifically, in step 2), the functional masterbatch accounts for 6% of the weight of the polyester chips.

[0028] Specifically, the silver ion powder is a nano silver ion inorganic antibacterial powder. It is prepared by ion exchange on nanom...

Embodiment 2

[0036] This embodiment discloses a kind of method for preparing silver ion antibacterial fiber, described method comprises the following steps:

[0037] 1) Melt and mix the silver ion powder, silicon-containing surfactant and polyester chips to obtain a functional master batch; the diameter of the silver ion powder is less than 0.5 μm; based on the total mass of the functional master batch, the The mass percentage of the silver ion powder is 18%, and the mass percentage of the silicon-containing surfactant is 5%; the silicon-containing surfactant is hexamethyldisiloxane;

[0038] 2) After mixing the functional masterbatch and polyester chips, add them to a screw extruder for spinning to obtain silver ion antibacterial fibers.

[0039] Specifically, in step 2), the functional masterbatch accounts for 5.5% of the weight of the polyester chips.

[0040] Specifically, the silver ion powder is a nano silver ion inorganic antibacterial powder. It is prepared by ion exchange on nan...

Embodiment 3

[0048] This embodiment discloses a kind of method for preparing silver ion antibacterial fiber, described method comprises the following steps:

[0049] 1) Melt and mix the silver ion powder, silicon-containing surfactant and polyester chips to obtain a functional master batch; the diameter of the silver ion powder is less than 0.5 μm; based on the total mass of the functional master batch, the The mass percentage of the silver ion powder is 20%, and the mass percentage of the silicon-containing surfactant is 6%; the silicon-containing surfactant is hexamethyldisiloxane;

[0050] 2) After mixing the functional masterbatch and polyester chips, add them to a screw extruder for spinning to obtain silver ion antibacterial fibers.

[0051] Specifically, the mass ratio of the functional masterbatch to the polyester chips is 5%.

[0052] Specifically, the silver ion powder is a nano silver ion inorganic antibacterial powder. It is prepared by ion exchange on nanometer zirconium pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com