Steel pipe driven pile foundation with steel boxed cofferdam and dual bearing platforms, and construction method of foundation

A construction method and a technology of steel casings, which are applied in infrastructure engineering, construction, etc., can solve the problems of increased project cost, long construction period, and enlargement, and achieve the effects of saving construction period, reliable quality, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

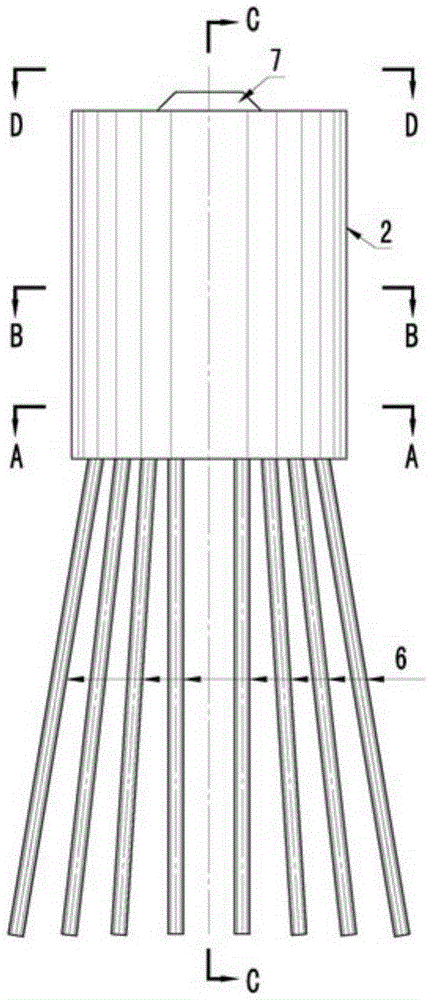

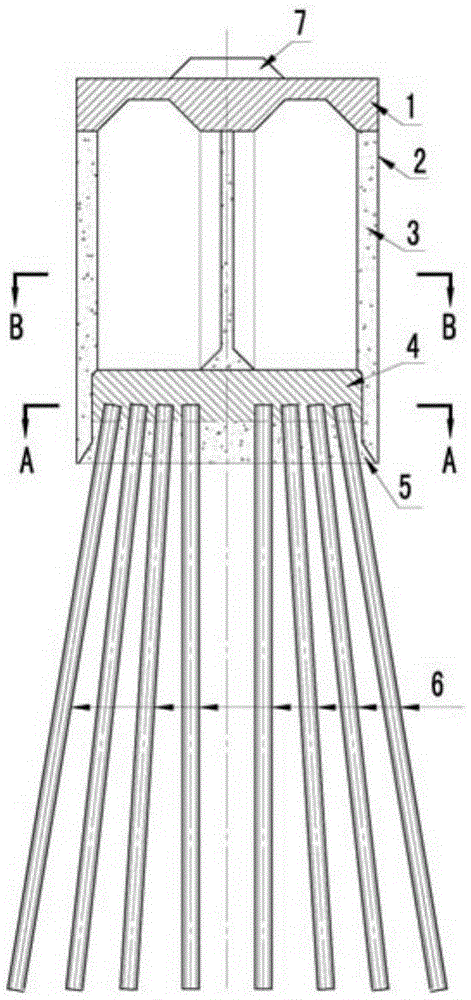

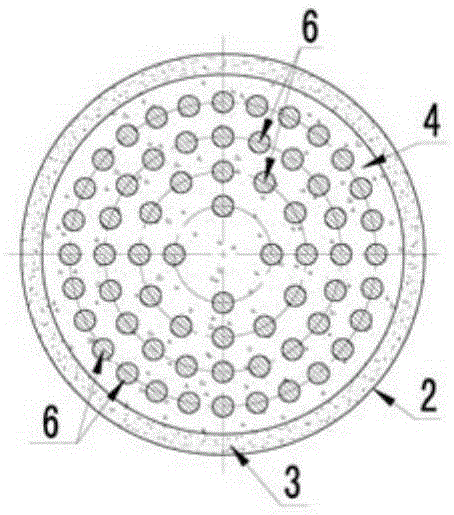

[0023] refer to figure 1 , 2 , 3, 4, 5, the steel box cofferdam double cap steel pipe driven pile foundation of the present invention is divided into upper and lower two parts, the upper part is the steel box cofferdam 2, and the lower part is the steel pipe driven pile foundation 6 The elevation of the steel pipe pile head of the steel pipe driving pile foundation is at the riverbed surface; There is an upper cap 1 on the steel casing cofferdam, and a tower or pier 7 is arranged on the upper cap. The upper platform 1 is a concrete structure, which can improve the durability of the structure.

[0024] The steel box cofferdam is a cofferdam formed by filling the steel box cofferdam thin-walled shell with concrete and filling the bottom with back-sealing concrete 5 . The thin-walled shell of the steel casing cofferdam is filled with concrete, which can improve the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com