Air filtration material filtering efficiency testing device

A technology of air filtration materials and filtration efficiency, which is applied in the fields of measurement devices, suspension and porous material analysis, permeability/surface area analysis, etc., and can solve the problems of air filtration efficiency that cannot be displayed intuitively and quickly, a large amount of data processing, and a long operation cycle etc. to achieve the effects of easy large-scale production, reduction of gas turbulence, and intuitive observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with accompanying drawing, the present invention will be further described:

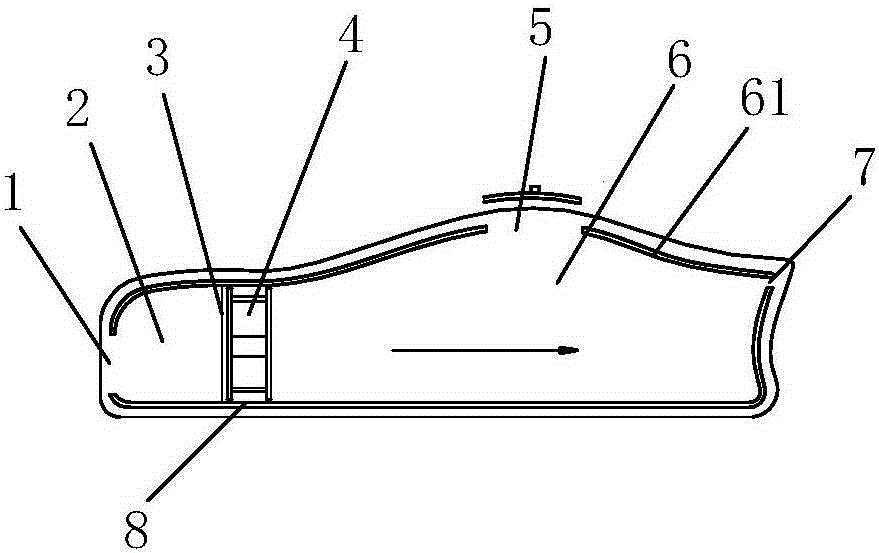

[0018] As shown in the figure, a filter efficiency testing device for air filter materials includes: an air inlet chamber 2 and an air measuring chamber 6, the air inlet chamber 2 is provided with an air inlet 1, and the air measuring chamber 6 is provided with an air outlet 7 and a test An air filter material 3 and a blower fan 4 are installed between the mouth 5, the air inlet chamber 2 and the gas measuring chamber 6.

[0019] The area of the air inlet 1 is greater than the area of the air port 7 .

[0020] The air inlet chamber 2 is in a negative pressure state, and the gas measuring chamber 6 is in a positive pressure state.

[0021] The air filter material 3 is located at the inlet or outlet of the blower fan 4 .

[0022] The gas measuring chamber 6 is provided with a curved surface 61 , and the test port 5 is located in the middle of the curved surface 61 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com