Detection circuit and carrier signal demodulation method of on-line monitor for lubricating oil and metal chips

A technology for detecting circuits and carrier signals, applied in the field of detection, can solve the problems of overlapping signals and inaccurate identification, and achieve the effects of unique and efficient demodulation method, ingenious and reasonable circuit structure, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further elaborate the present invention below in conjunction with specific implementation case

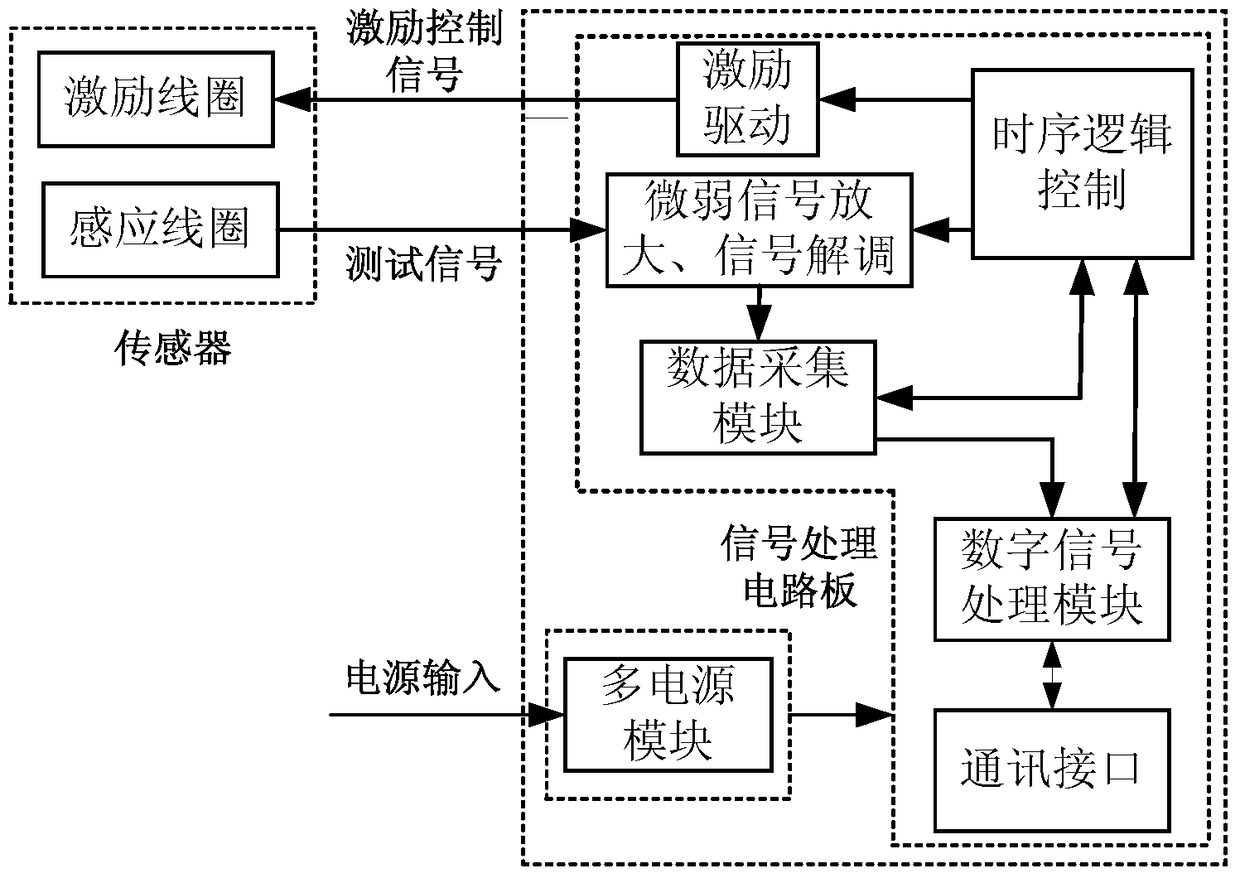

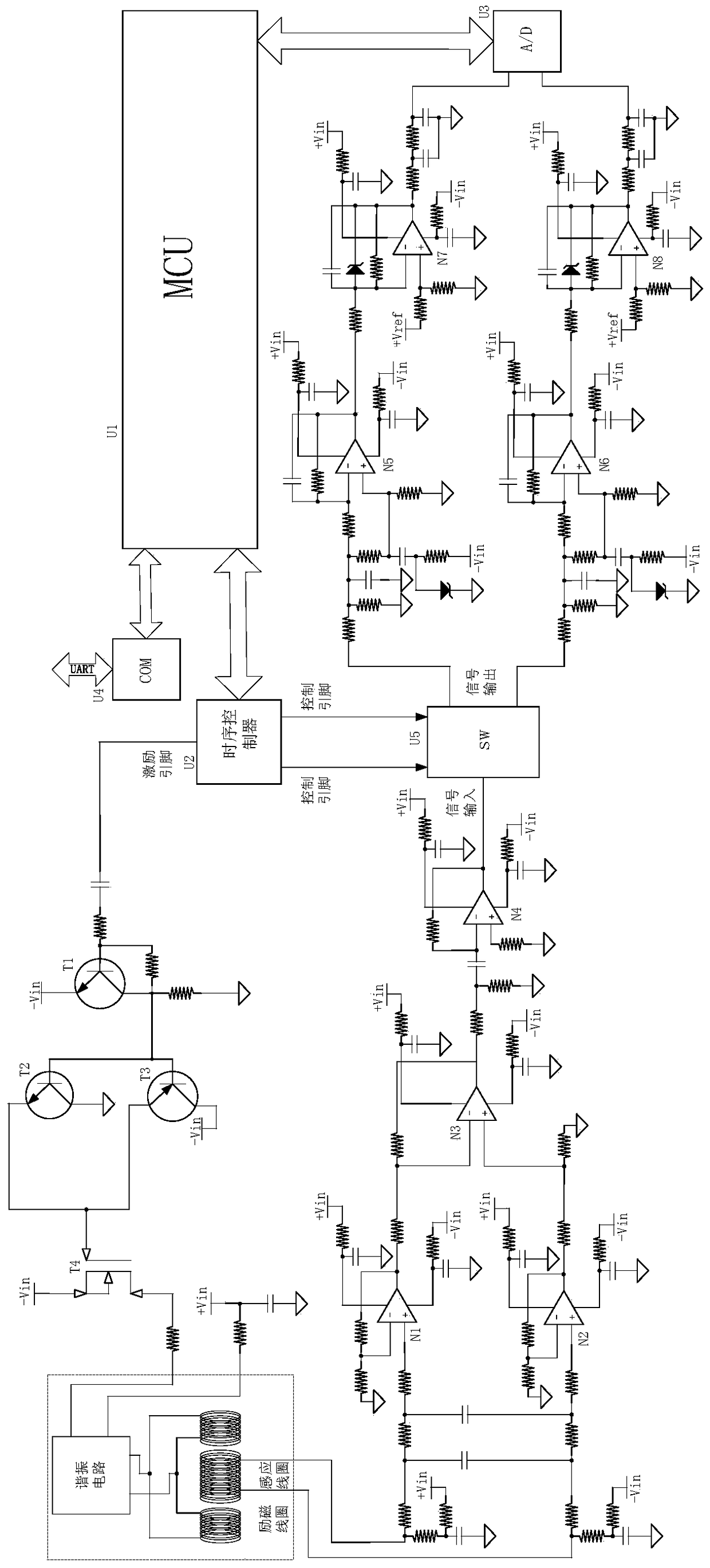

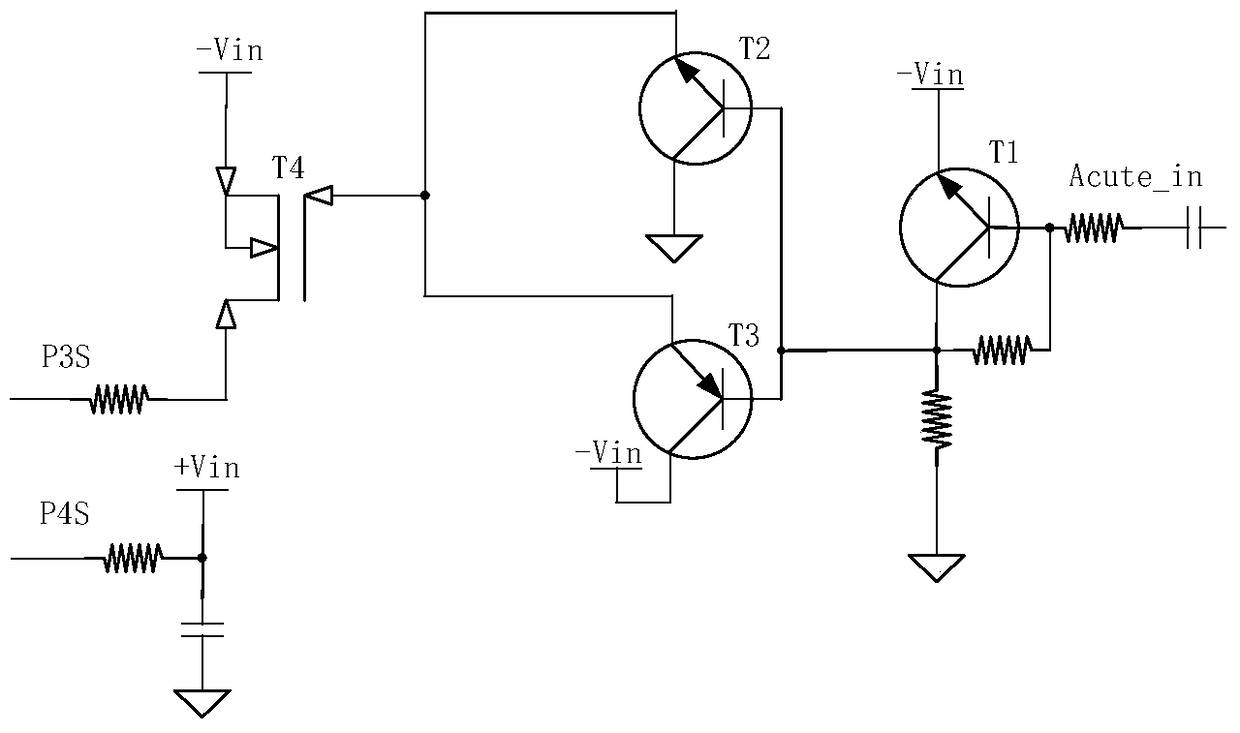

[0017] see figure 2 , the detection device includes an excitation coil and an induction coil. After the timing controller U2 in the circuit is programmed, one of the excitation pins of the timing controller U2 generates a square wave with a fixed frequency H and a fixed pulse width T, and the two control pins Generate two channels with the same frequency H and different pulse width T 1、 T 2 square wave; the square wave input excitation circuit generated by the excitation pin of the controller U2, for details, see image 3 , the square wave is processed by the transistors T1, T2 and T3 to realize the conduction and shutdown of the field effect transistor T4, and the similar square wave signal output by the field effect transistor T4 acts on the resonant circuit in the lubricating oil metal chip detection device to generate The fixed-frequency sine wave AC excitation signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com