Electrically conductive aluminum alloy plate and method for manufacturing same

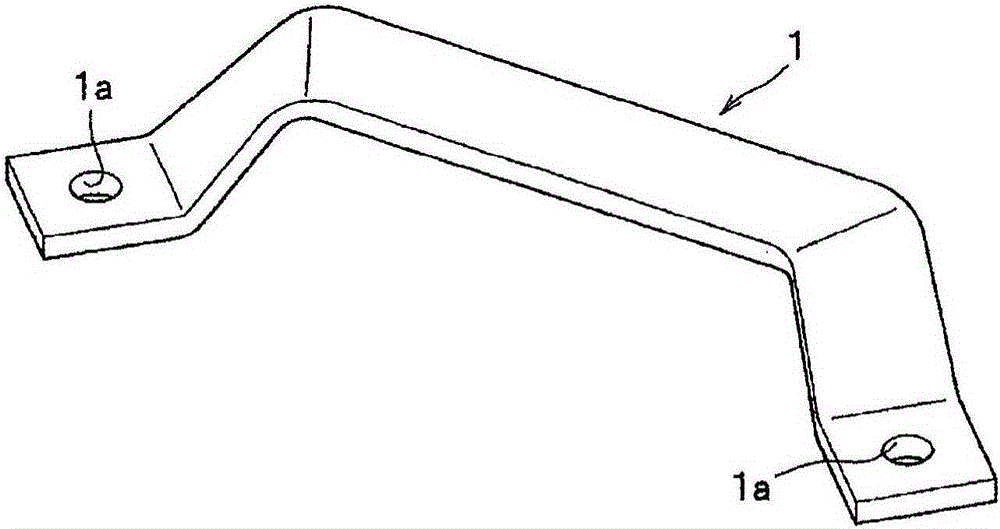

A technology of aluminum alloy plate and manufacturing method, which is applied in the direction of cable/conductor manufacturing, conductive material, conductive material, etc., can solve the problems of reduced bending processability of the plate, detachment of the connecting part 1a, and no consideration of stress relaxation characteristics, etc., to achieve Excellent effect of maintaining electrical conductivity, stress relaxation characteristics, and bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0144] Next, the aluminum alloy plate for electrical conduction of this invention and its manufacturing method are demonstrated concretely by comparing the Example which satisfied the requirement of this invention, and the comparative example which did not satisfy the requirement of this invention.

[0145] [Preparation of test material]

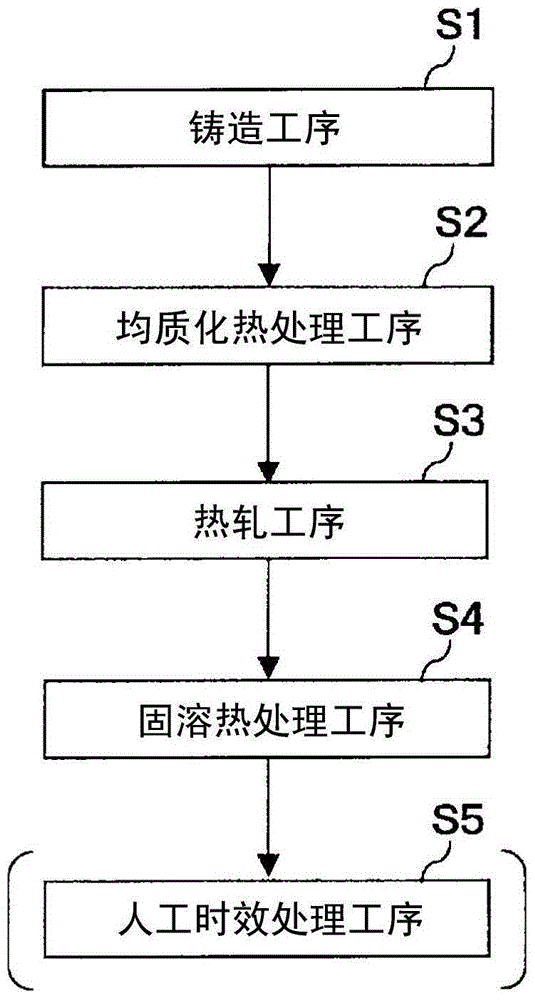

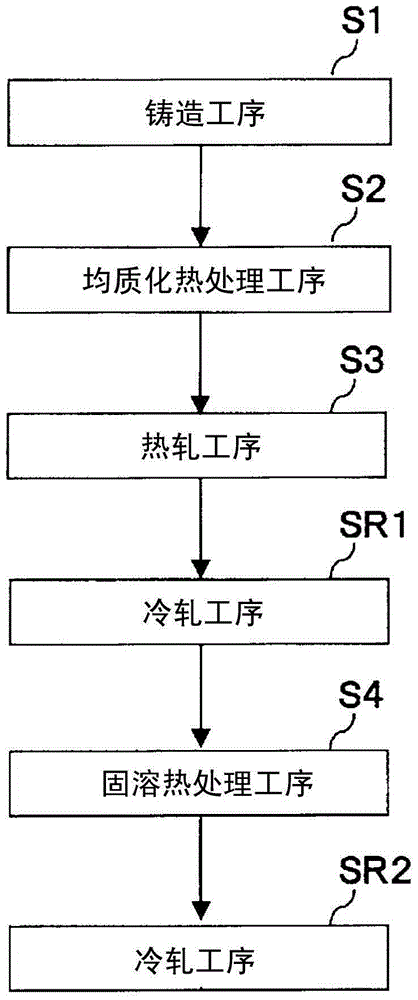

[0146] Aluminum alloys (alloys 1 to 22) having the compositions shown in Table 1 were melted, and ingots were produced by semi-continuous casting, and face cutting was performed. The ingot was homogenized and heat-treated under the conditions shown in Table 2, and then hot-rolled at a rolling ratio of 99% to obtain a hot-rolled sheet. Thereafter, cold rolling was implemented (excluding some test materials), and solution heat treatment was performed under the conditions shown in Table 2. Then, after the solution heat treatment, cold rolling was performed (except for some test materials), and the artificial aging treatment shown in Table 2 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap