Yogurt and preparation method thereof

A yogurt and drying technology, which is applied in milk preparations, dairy products, applications, etc., to achieve the effects of rich nutrition, strong stability, and good flavor and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

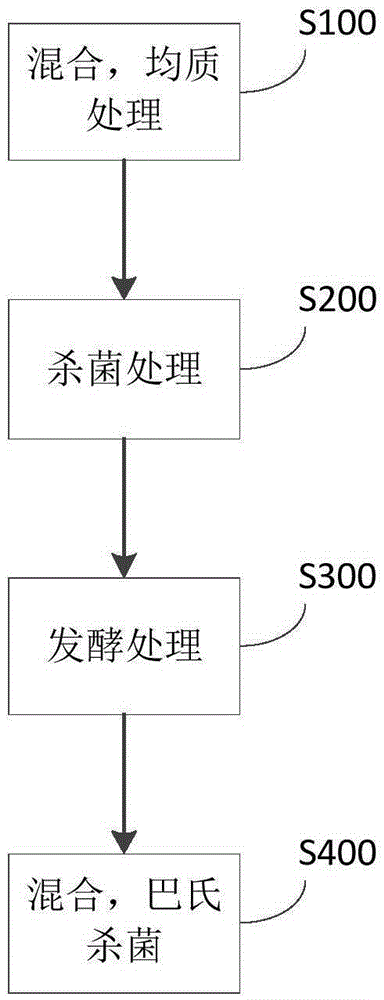

Method used

Image

Examples

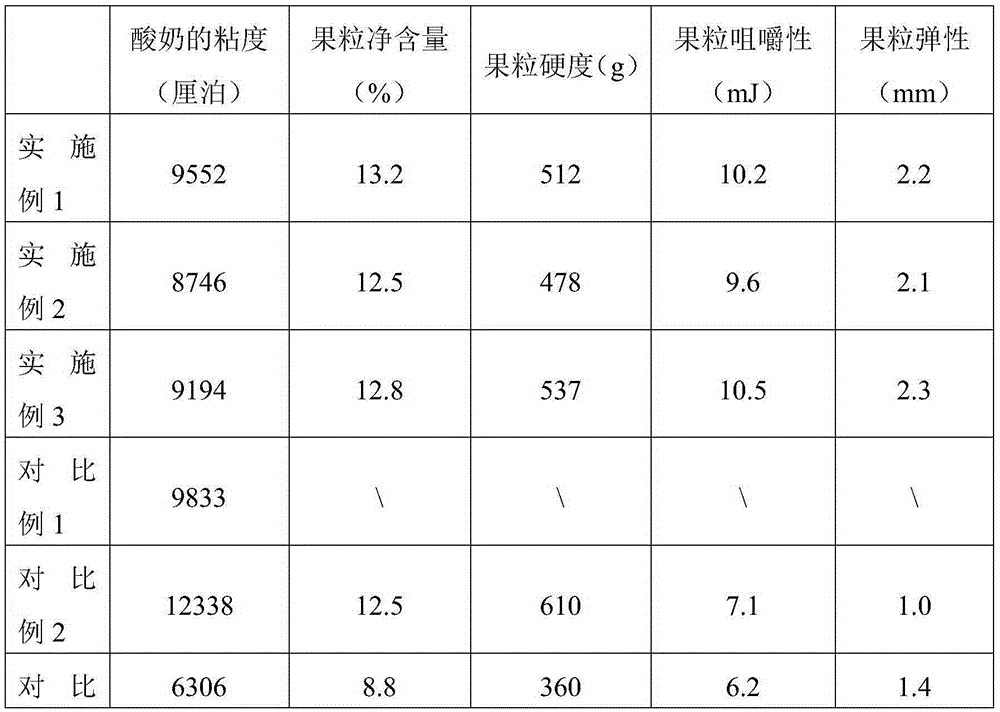

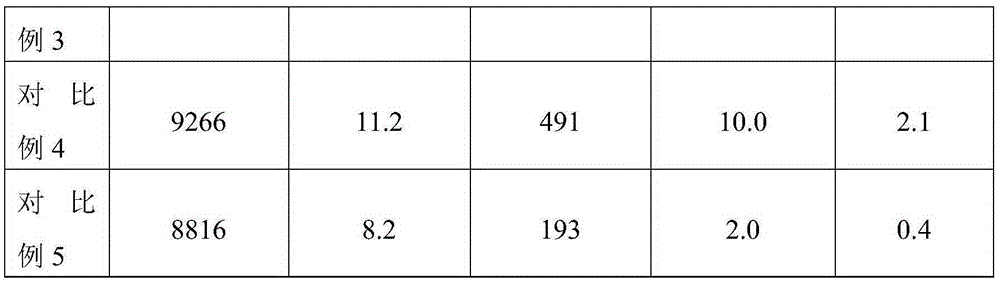

Embodiment 1

[0067] In this example, yogurt was prepared by the following steps:

[0068] (1) 20 grams of physically modified starch, 1 gram of propylene glycol alginate, 0.3 gram of monoglyceride citrate, 3 grams of pectin, 0.5 gram of agar and 90 grams of white granulated sugar are dry mixed, and then Add 50 degrees Celsius milk to the mixture through a high-speed mixer, mix at 1500 rpm for 15 minutes, then add 1 gram of cream and 3 grams of whey protein powder to the resulting mixture, and mix at 1500 rpm Mix for 30 minutes under the speed of rotation, and then make up to 1000 grams with milk.

[0069] (2) Homogenize the mixture obtained in step (1) at a temperature of 45 degrees Celsius and a pressure of 200 bar, and sterilize the homogeneous product at a temperature of 75 degrees Celsius for 300 seconds, and then cool the sterilized product to 35 Celsius.

[0070] (3) Add 0.2U of Lactobacillus bulgaricus and Streptococcus thermophilus in the mixture obtained in step (2) with a ratio...

Embodiment 2

[0075] In this example, yogurt was prepared by the following steps:

[0076] (1) 10 grams of physically modified starch, 0.5 grams of propylene glycol alginate, 0.15 grams of monoglyceride citrate, 3 grams of pectin, 3 grams of agar and 40 grams of white sugar are dry mixed, and then The mixture is passed through a high-speed mixer to add milk at 10 degrees Celsius, and mix at a speed of 1500 rpm for 30 minutes, then add 10 grams of cream and 10 grams of whey protein powder to the resulting mixture, and mix at a speed of 1500 rpm Mix for 20 minutes under the speed of rotation, and then make up to 1000 grams with milk.

[0077] (2) Homogenize the mixture obtained in step (1) at a temperature of 75 degrees Celsius and a pressure of 120 bar, and sterilize the homogeneous product at a temperature of 105 degrees Celsius for 200 seconds, and then cool the sterilized product to 25 Celsius.

[0078] (3) Add 0.05U of Streptococcus thermophilus at a ratio of 2:3 to the mixture obtaine...

Embodiment 3

[0083] In this example, yogurt was prepared by the following steps:

[0084] (1) 15 grams of physically modified starch, 1 gram of propylene glycol alginate, 0.3 gram of monoglyceride citrate, 1.75 grams of pectin, 1.75 grams of agar and 65 grams of white sugar are dry mixed, and then Add 30 degrees Celsius milk to the mixture through a high-speed mixer, mix at 1500 rpm for 15 minutes, then add 5 grams of cream and 6 grams of whey protein powder to the resulting mixture, and mix at 1500 rpm Mix for 25 minutes under the speed of rotation, and then make up to 1000 grams with milk.

[0085] (2) Homogenize the mixture obtained in step (1) at a temperature of 60 degrees Celsius and a pressure of 160 bar, and sterilize the homogeneous product at a temperature of 90 degrees Celsius for 250 seconds, then cool the sterilized product to 45 Celsius.

[0086] (3) Add 0.12 U of Streptococcus thermophilus at a ratio of 2:3 to the mixture obtained in step (2), and ferment for 12 hours at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com