Tea aroma rice crust and making method thereof

A production method and the technology of tea-flavored crispy rice, which are applied in food ingredients as taste improvers, food ingredients as odor improvers, food science, etc., can solve problems such as low nutritional content, too many additives, and difficulty in popularization. Achieve the effect of good uniform mixing, low production cost and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the tea-flavored crispy rice is mainly made from the following raw materials in parts by weight: 35 parts of rice, 15 parts of mung beans, 10 parts of oatmeal, 10 parts of green tea seed oil, 2 parts of dried green tea, 5 parts of citrus peel, and 0.8 part of table salt . The green tea seed oil is tea seed oil extracted by cold pressing.

[0037] The production method is as follows:

[0038] S1: Weighing the above raw materials in parts by weight, grinding rice and mung beans into powder, and chopping dried green tea and citrus peel;

[0039] S2: Put the processed rice, mung beans, oatmeal, dried green tea, and citrus peels into a blender for stirring, and put green tea seed oil and salt in the middle to make the stirring evenly and form a dough;

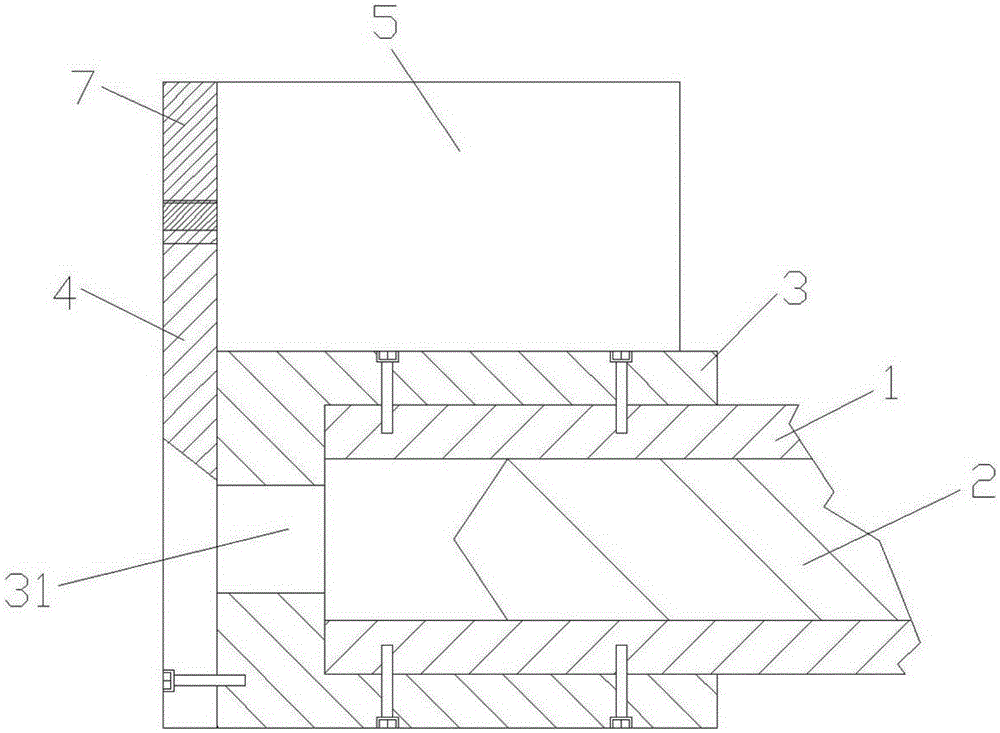

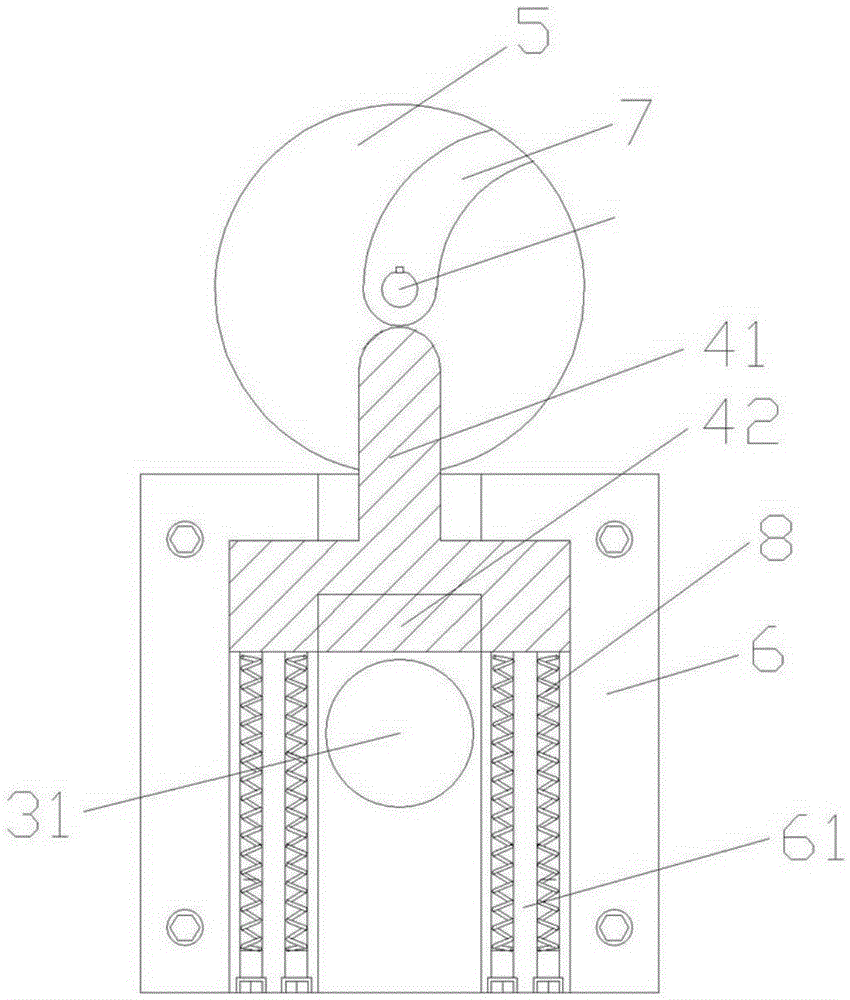

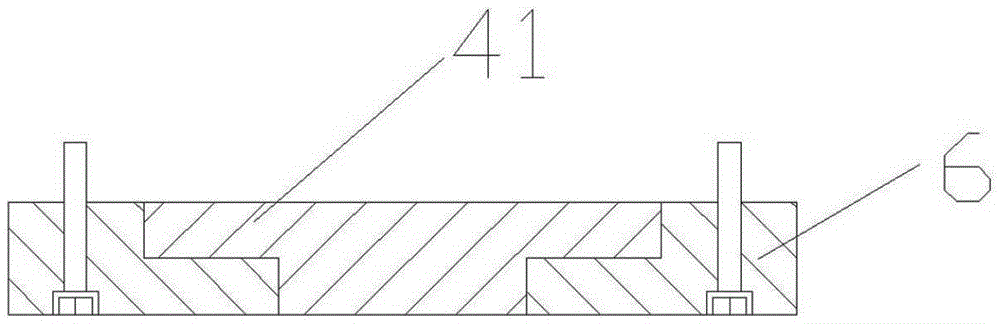

[0040] S3: Put the dough into a rice crust mold for extrusion, and cut into dough sheets with a thickness of 3mm;

[0041] S4: The cut dough pieces fall to the baking belt set under the extrusion end of th...

Embodiment 2

[0044] In this example, the tea-flavored crispy rice is mainly made from the following raw materials in parts by weight: 40 parts of rice, 10 parts of mung beans, 15 parts of oatmeal, 8 parts of green tea seed oil, 1 part of dried green tea, 4 parts of citrus peel, and 0.8 part of table salt . The green tea seed oil is tea seed oil extracted by cold pressing.

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0047] In this example, the tea-flavored crispy rice is mainly made from the following raw materials in parts by weight: 40 parts of rice, 20 parts of mung beans, 10 parts of oatmeal, 10 parts of green tea seed oil, 3 parts of dried green tea, 4 parts of citrus peel, and 3 parts of honey , 3 parts of water chestnuts, 5 parts of crushed ice, and 1 part of table salt. The green tea seed oil is tea seed oil extracted by cold pressing.

[0048] The production method is as follows:

[0049] S1: Weighing the raw materials in the above parts by weight, grinding rice and mung beans into powder, and chopping dried green tea, citrus peels and water chestnuts;

[0050] S2: Put the processed rice, mung beans, oatmeal, dried green tea, citrus peel, water chestnuts, and crushed ice into the blender for stirring, and put green tea seed oil, honey, and salt in the middle, make the stirring evenly, and form a dough;

[0051] S3: put the dough into a rice crust mold for extrusion, and cut int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com