Rose water extract and preparation method thereof

A rose water extract and rose technology, which is applied in the field of drinking water, can solve the problems such as the inability to fully extract the beneficial substances of rose petals and the entry of human body substances into water and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

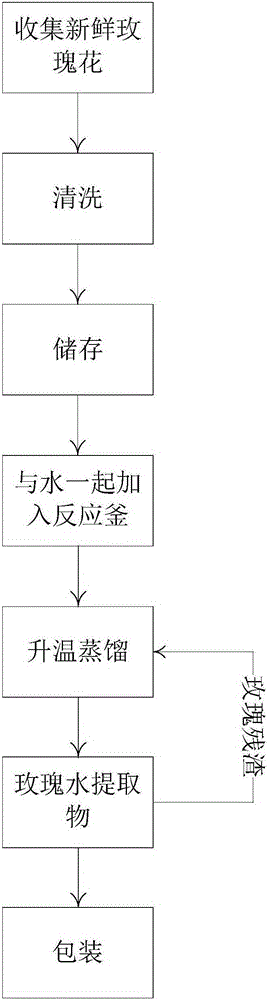

[0020] Such as figure 1 Shown, the preparation method of rose water extract of the present invention comprises the following main steps:

[0021] 1) Collect fresh roses. The rose species of the rose raw material for the production of rose water extract is preferably Damascus rose, which is a world-recognized fine variety, and the purpose is to ensure the quality of roses, and then ensure the quality of active rose water. Of course, roses of other varieties can also be used, which is not limited here. Roses are required to be picked from the end of April or early May. The picked roses should have just opened, bright in color, and shaped like a cup. The best specific time is 5:00--7:00 in the morning, the most suitable ambient temperature for picking is 15-23°C, and the relative humidity is 55%-70%. The freshly picked rose petals are also covered with dew, and the essential oil content is the highest when the rose is just open, which is conducive to improving the quality of t...

Embodiment 1

[0029] Weigh 10kg of the pollution-free green product rose flower produced by Jinyuan Rose Garden, wash it once with clear water, drain the cleaning water, wash it once with deionized water, drain the cleaning water, put it into the extraction kettle, and then add it to the 15kg of ionized water, steam is slowly passed into the interlayer of the extraction kettle, the temperature in the extraction kettle rises slowly, and rises to 80°C in 60 minutes, and then continues to heat until it boils slightly, and distillate begins to distill out, and the distillate exits The temperature is 30°C.

[0030] Slightly increase the amount of heating steam, the speed of the distillate is accelerated, the outlet temperature of the distillate reaches 40°C, the flow rate is 170±5ml / min, a total of 8kg of the extract is distilled in 2 hours, the heating is stopped, and the remaining flower residue in the kettle is extracted.

[0031] Add 5kg of deionized water to the flower residue, heat to boil...

Embodiment 2

[0033] Weigh 12kg of the pollution-free green product rose flowers produced by Jinyuan Rose Garden, wash them once with clear water, drain the cleaning water, wash them twice with deionized water, drain the cleaning water, put them into the extraction kettle, and then add them to the 15kg of ionized water, steam is slowly passed into the interlayer of the extraction kettle, the temperature in the extraction kettle rises slowly, and rises to 70°C in 40 minutes, and then continues to heat until it boils slightly, and distillate begins to distill out, and the distillate exits The temperature is 35°C.

[0034] Slightly increase the amount of heating steam, the speed of the distillate is accelerated, the outlet temperature of the distillate reaches 45°C, the flow rate is 150±5ml / min, a total of 7kg of the extract is distilled in 2 hours, the heating is stopped, and the remaining flower residue in the kettle is extracted.

[0035]Add 6kg of deionized water to the flower dregs, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com