Device for preheating die by means of waste gas of die casting smelting furnace

A furnace and waste gas technology, used in waste heat treatment, furnaces, furnace components, etc., can solve problems such as cost increase and energy waste, and achieve the effect of saving energy, reducing costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

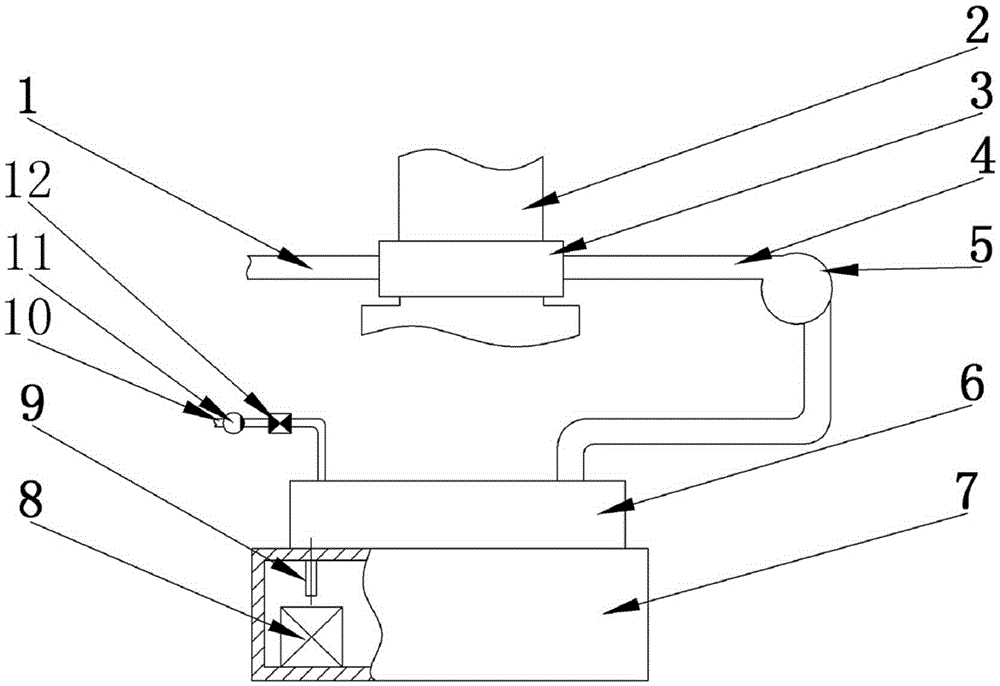

[0012] The reference signs in the drawings of the description include: air intake pipe 1, high temperature flue gas pipe 2, heat exchanger 3, hot air pipe 4, high temperature fan 5, mixing chamber 6, preheating chamber 7, mold 8, nozzle 9 , cold air pipeline 10, air pump 11, controllable valve 12.

[0013] The embodiment is basically as attached figure 1 Shown:

[0014] In this solution, the device for preheating the mold by using the exhaust gas of the die-casting furnace includes an air intake pipe 1, one end of which is connected to the atmosphere, and one end of which is connected to the heat exchanger 3, which is made of corundum in this embodiment. Ceramic heat exchanger. The heat exchanger 3 itself is installed on the high-temperature flue gas pipeline 2 of the die-casting furnace, and its function is to use the high-temperature flue gas to heat the air flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com