Polishing method for high-rise deep-concave spherical lens

A concave spherical, high-depth technology, used in lenses, grinding/polishing equipment, optics, etc., can solve the problems of increasing production cost and cycle, affecting processing quality and efficiency, and high manufacturing cost, achieving convenient operation, improving processing efficiency, The effect of simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

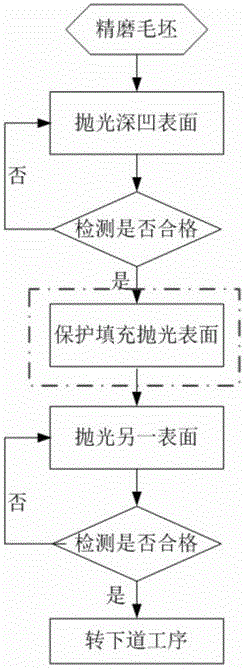

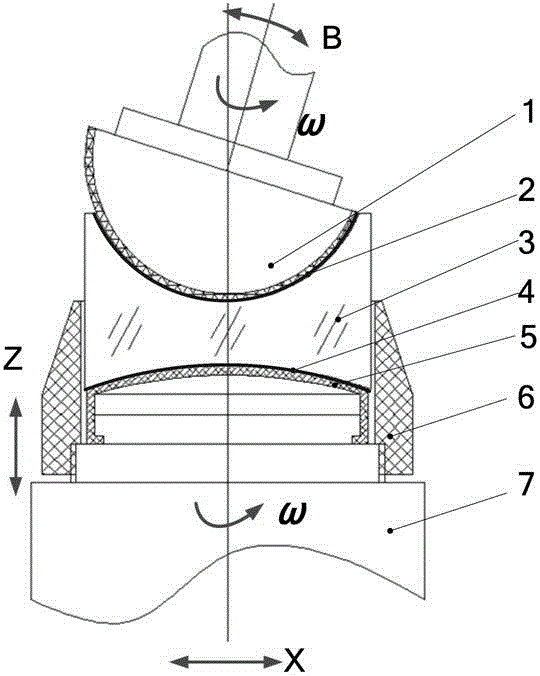

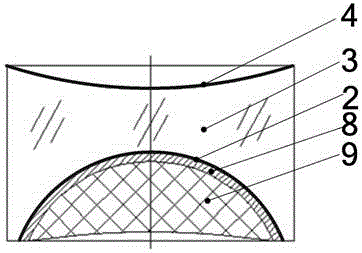

[0027] refer to Figure 1 to Figure 3 As shown, the polishing method for the large-scale high-deep concave spherical lens provided in this embodiment adopts the method of filling the deep concave spherical support surface, and simultaneously adopts the method of combining large and small polishing discs, and specifically includes the following steps:

[0028] Step a: Turn on the machine tool, put the optical lens 3 to be polished after fine grinding into the inside of the machine tool support tool 6, the surface 2 of the Oyako high-deep concave ball to be polished is upward, and install the polishing disc 1 with a radius corresponding to the Oyako high-deep concave ball surface 2, Start the polishing process;

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com