Corrosion-resistant elevator color-coated sheet

A color-coated board and corrosion-resistant technology, which is applied to anti-corrosion coatings, elevators in buildings, coatings, etc., can solve the problems of elevator board surface damage, non-environmental protection, and pungent smell of maintenance wax, and achieve the goal of improving structural toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0021] This case proposes an embodiment of a corrosion-resistant elevator color-coated plate, which is sequentially provided with a top coat, a primer coat, a passivation layer, and a substrate layer from top to bottom;

[0022] The specific material of the substrate layer may not be limited, and is generally galvanized sheet. The specific composition of the passivation layer is also not limited, and the passivation solution and its passivation process also belong to the prior art, and the passivation layer is generally a trivalent chromium skin salt film.

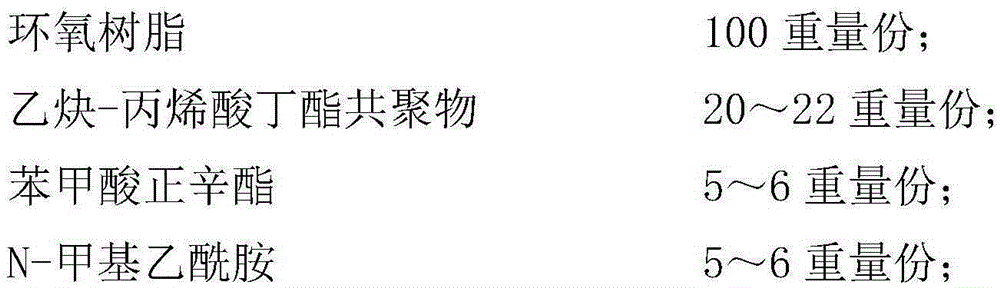

[0023] The top coat comprises the following materials in parts by weight:

[0024]

[0025] Acetylene-butyl acrylate copolymer can improve the bonding strength of epoxy resin and polyurethane resin, and the acetylene molecules ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com