A semi-automatic control method of portal crane

A technology of portal cranes and cranes, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high driver dependence, uncertain working conditions of portal cranes, and high labor intensity, so as to increase detection means and reduce Labor intensity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

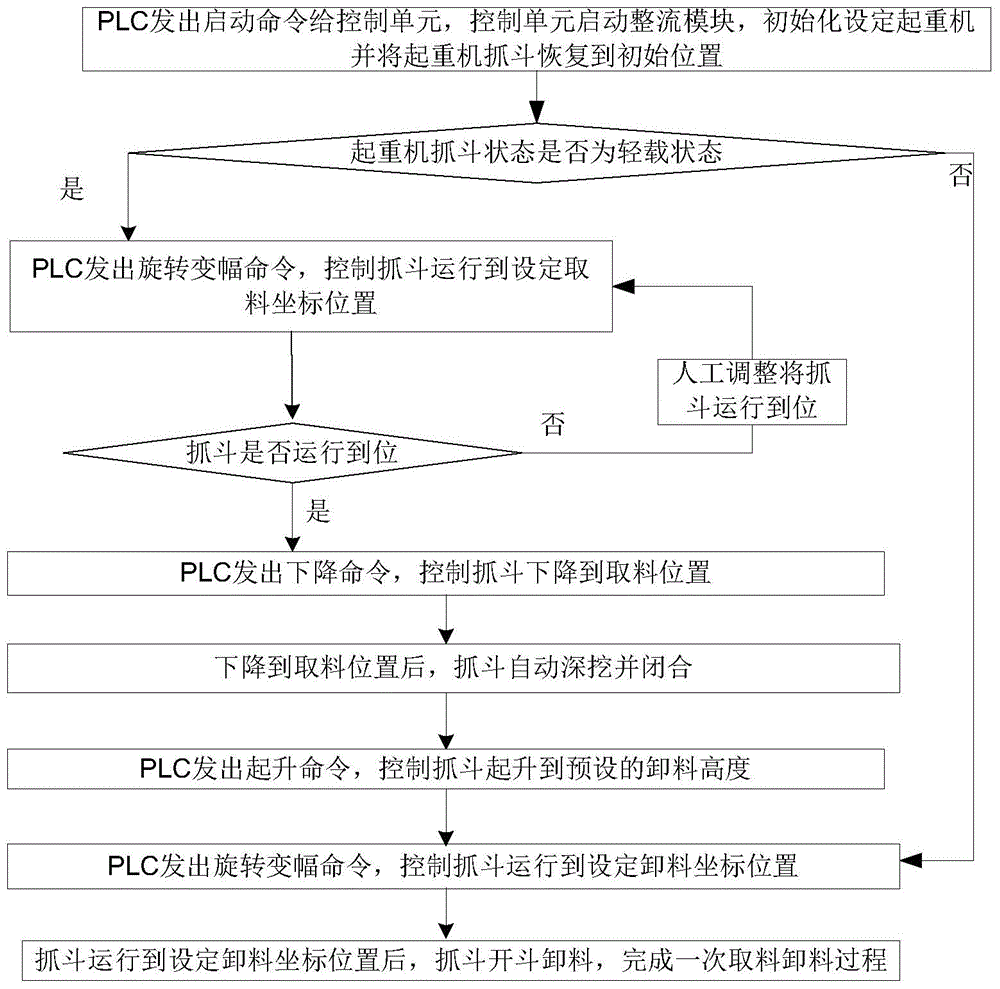

[0029] A semi-automatic control method for a gantry crane, with a programmable logic controller (abbreviated as PLC) as the core, driven by an industrial frequency converter, and an instrument-electrical integration system composed of an encoder and a tension sensor.

[0030] When the two door cranes of the crane are grabbing and unloading the ship on the shore, if they are very close to each other and loading and unloading the same cabin, when the two door cranes rotate, the elephant trunk boom may collide, causing damage to the door crane. If the door crane is unloaded with a hook, it may collide with the hull mast crane, cockpit and related equipment on the hull when the door crane changes its amplitude or rotates, causing damage to the door crane and the hull. In order to solve the anti-collision problem, three laser scanners are installed under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com