Method for preparing porous-structure VO2 film with polystyrene bead as soft template

A technology of polystyrene pellets and porous structure, which is applied in the field of preparation of porous structure VO2 film, can solve the problems of single method and reduce the phase transition temperature of the film, and achieve the effects of low preparation process cost, reduced reflection, and low phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 6.0g chemically pure coarse crystal vanadium pentoxide (V 2 o 5 ), ground and mixed with 8.9g of analytically pure oxalic acid (C 2 h 2 o 4 ) into 200ml of absolute ethanol, stirred in a beaker until all the raw materials were dissolved, added 1.5g of polyvinylpyrrolidone (PVP), stirred for 20min, then transferred the solution into a four-neck flask, heated and stirred in an oil bath at 120°C for 12h, and then added dispersing There is 15ml of absolute ethanol emulsion of polystyrene beads, drop into 5.0ml of absolute ethanol solution of surfactant P123, and continue stirring at room temperature until a uniform emulsion sol is formed. Coating by spin coating method, spin coating at 2500r / min for 20s to obtain a wet film, drying in an oven at 100°C for 10min, and then drying in N 2 Under the protection of gas atmosphere, the porous structure of VO was obtained by holding it at 550°C for 30 minutes. 2 film.

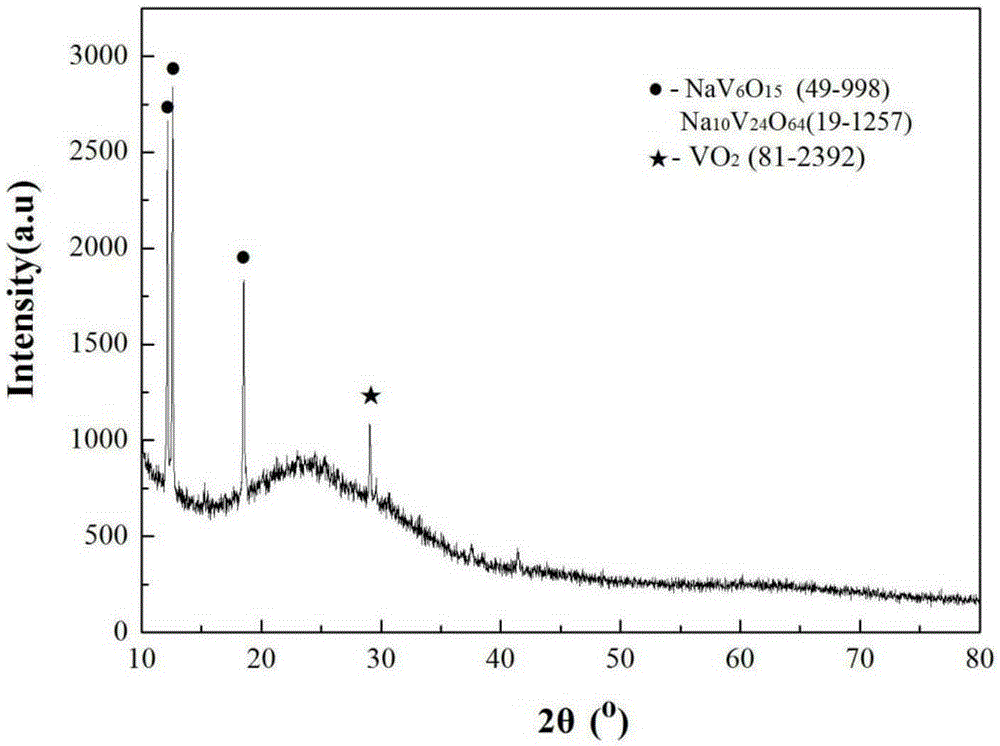

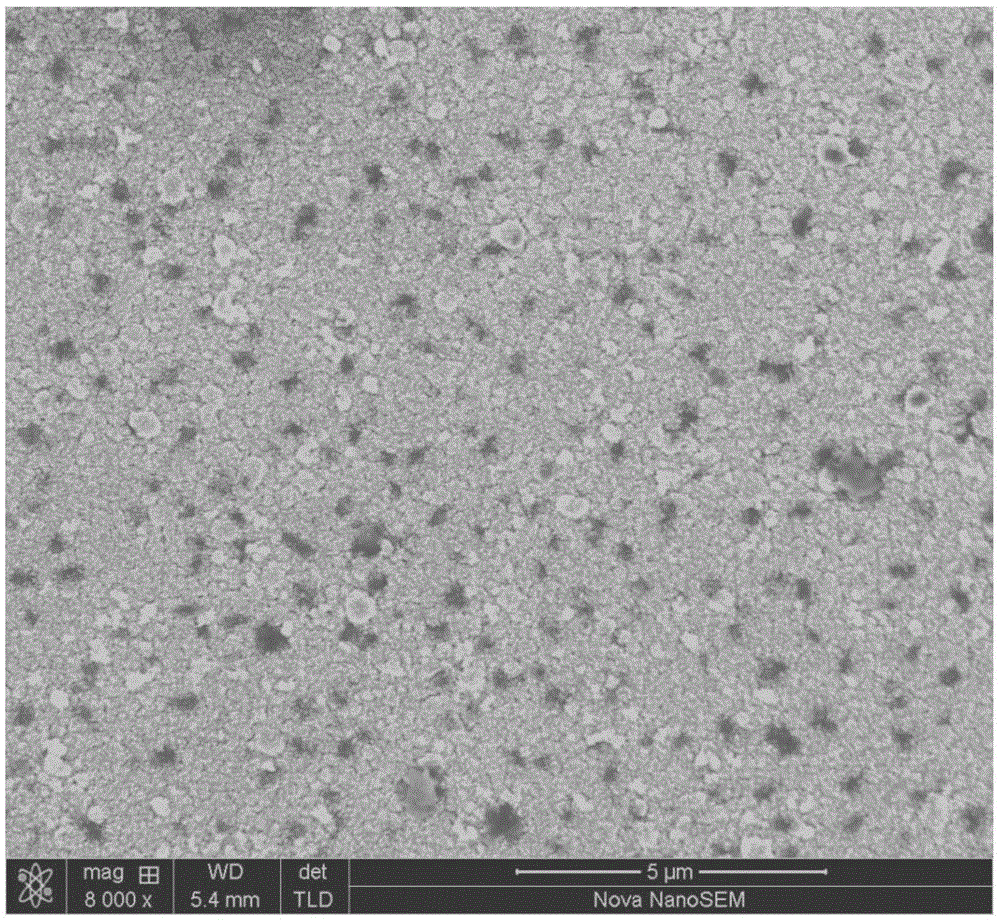

[0028] figure 1 VO prepared for this example 2 Th...

Embodiment 2

[0030] This embodiment is a comparative experiment of embodiment 1.

[0031] Weigh 6.0g chemically pure coarse crystal vanadium pentoxide (V 2 o 5 ), ground and mixed with 8.9g of analytically pure oxalic acid (C 2 h 2 o 4 ) into 200ml of absolute ethanol, stir in a beaker until all the raw materials are dissolved, add 1.5g of polyvinylpyrrolidone (PVP), stir for 20min, transfer the solution into a four-neck flask, heat and stir in an oil bath at 120°C for 12h to obtain a coating precursor Sol. Coating by spin coating method, spin coating at 2500r / min for 20s to obtain a wet film, drying in an oven at 100°C for 10min, and then drying in N 2 VO was obtained by holding it at 550°C for 30 minutes under the protection of gas atmosphere. 2 film.

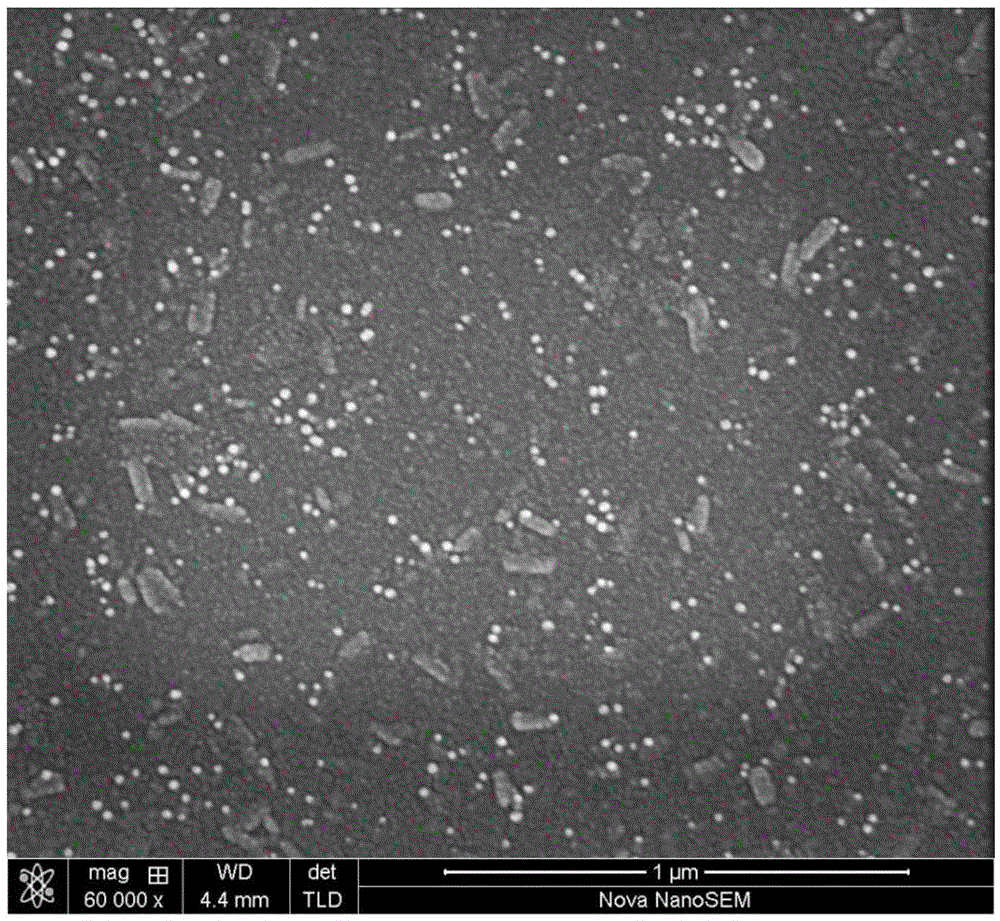

[0032] figure 2 VO prepared for this example 2 Thin film SEM pictures. Figure 4 VO prepared for this example 2 Hysteresis curves of thin film phase transition properties.

[0033] Comparing the phase transition characteristic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com