Method for preparing high-concentration hydrazine hydrate

A hydrazine hydrate, high-concentration technology, applied in the chemical field of azeotropic distillation, can solve the problems of high equipment requirements, cumbersome operation, large energy consumption, etc., and achieve the effects of increasing the concentration of hydrazine hydrate, increasing the concentration, and reducing the requirements of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

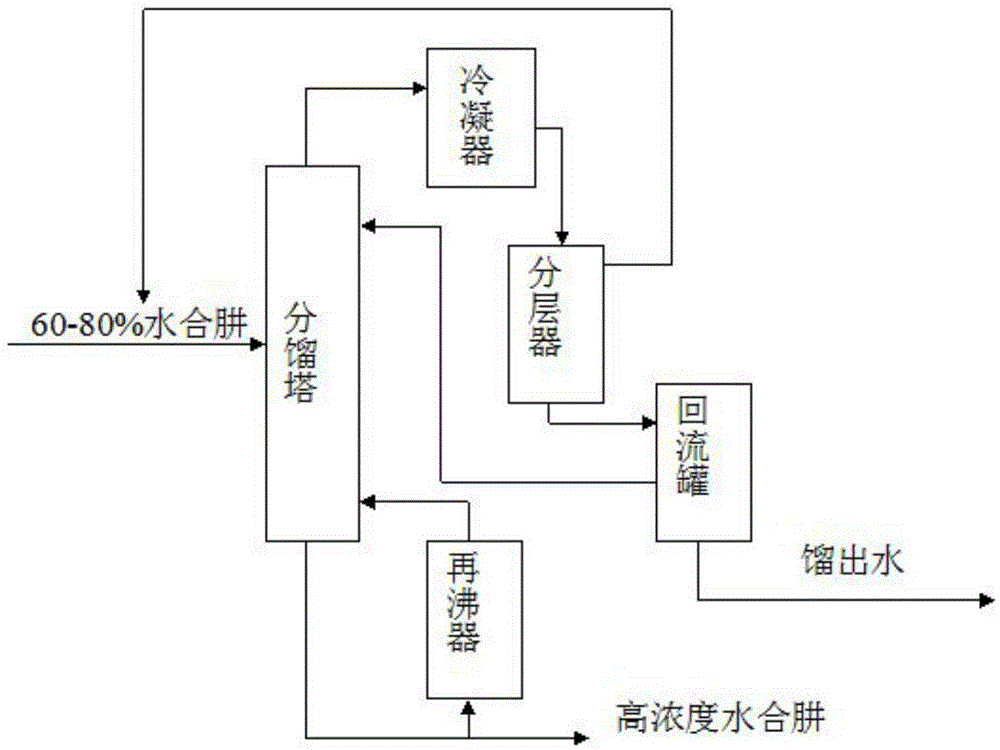

Method used

Image

Examples

Embodiment 1

[0019] Add 800g of 80% hydrazine hydrate and 100ml of toluene into a 1L three-neck flask, use a rectification device consisting of a 500mm thorn-type distillation column, a spherical condenser, and a layerer to conduct heating, and control the temperature in the flask to 118°C~120°C to control the distillation The temperature at the top of the column is 100°C~102°C. After the gas is condensed, it enters the stratifier. The upper layer of toluene overflows into the dropping funnel and is added to the three-necked flask. The water containing hydrazine hydrate in the lower layer enters the collection bottle. Constantly taken out by the entrainer, hydrazine hydrate and water are separated, and the hydrazine hydrate concentration is getting higher and higher. When there is almost no water in the distillate, the test is stopped, and the hydrazine hydrate content is analyzed after cooling to obtain 99.5% hydrazine hydrate 513g.

Embodiment 2

[0021] Add 800g of 80% hydrazine hydrate and 190ml of toluene into a 1L three-neck flask, use a rectification device consisting of a 500mm thorn-shaped distillation column, a spherical condenser, and a layerer to conduct heating, control the temperature in the flask to 118°C~120°C, and control the distillation The temperature at the top of the column is 100°C~102°C. After the gas is condensed, it enters the stratifier. The upper layer of toluene overflows into the dropping funnel and is added to the three-necked flask. The water containing hydrazine hydrate in the lower layer enters the collection bottle. Constantly taken out by the entrainer, hydrazine hydrate and water are separated, and the concentration of hydrazine hydrate is getting higher and higher. When there is almost no water in the distillate, the test is stopped. After cooling, the hydrazine hydrate content is analyzed to obtain 99.7% hydrazine hydrate 516g.

Embodiment 3

[0023] Add 800g of 60% hydrazine hydrate and 80ml of aniline into a 1L three-neck flask, use a rectification device consisting of a 500mm thorn-shaped distillation column, a spherical condenser, and a stratifier to conduct heating, and control the temperature in the flask to 118°C~120°C to control the distillation. The temperature at the top of the column is 100°C~102°C. After the gas is condensed, it enters the stratifier. The upper layer of toluene overflows into the dropping funnel and is added to the three-necked flask. The water containing hydrazine hydrate in the lower layer enters the collection bottle. Constantly taken out by the entrainer, hydrazine hydrate and water are separated, and the hydrazine hydrate concentration is getting higher and higher. When there is almost no water in the distillate, the test is stopped, and the hydrazine hydrate content is analyzed after cooling to obtain 99.3% hydrazine hydrate 510g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com