Microbe capable of producing aflatoxin B1 (AFB1) degrading enzyme and application thereof

A kind of aflatoxin, degrading enzyme technology, applied in the field of microorganisms, can solve problems such as aflatoxin pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the screening of strain

[0045] (1) Screening samples

[0046] Rotten Peanut Shells

[0047] (2) Medium

[0048] Every 1L of the enriched medium contains: coumarin 1g, (NH 4 ) 2 SO 4 5g, NaCl8.5g, the pH of the enrichment medium is natural;

[0049] The primary screening medium per 1L contains: coumarin 1g, (NH 4 ) 2 SO 4 5g, KH 2 PO 4 2.5g, MgSO 4 1g,NaH 2 PO 4 ﹒ 12H 2 O0.5g, FeSO 4 ﹒ 7H 2 O0.1g, CaCl 2 0.1g, 20g of agar, the pH of the primary screening medium is 6.0-6.5;

[0050] Each 1 L of the slant medium contains: 200 g of potatoes, 20 g of glucose, and 20 g of agar, and the pH of the slant medium is natural;

[0051] Each 1L of the seed medium contains: 200g of potatoes, 20g of glucose, 1.0mL of Tween80, and the pH of the seed medium is natural;

[0052] Each 1L of the re-screened medium contains: 30g of sucrose, NaNO 3 2.0g, K 2 HPO 4 ·3H 2 O1.0g, KCl0.5g, MgSO 4 0.5g, FeSO 4 ·7H 2 O0.01g, pH natural;

[0053] (3) Th...

example 2

[0068] Example 2: The culture condition optimization of CCTCCNO:M2015181

[0069] (1) Strain: CCTCCNO:M2015181

[0070] (2) Method steps

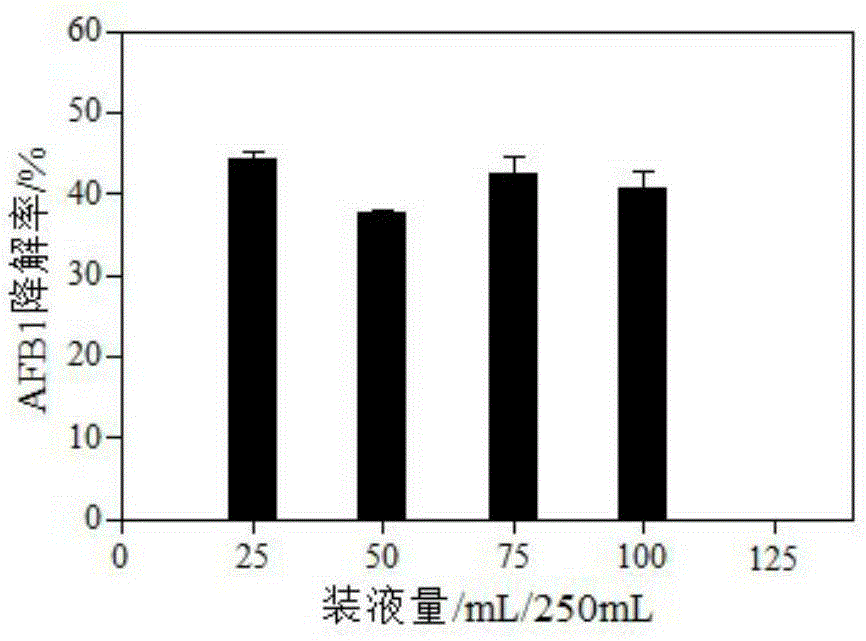

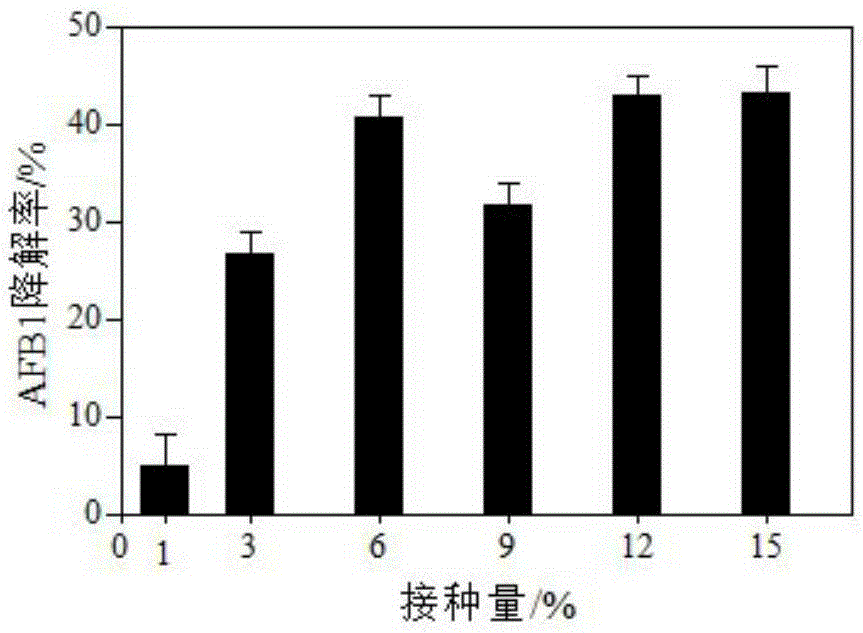

[0071] The fermentation medium is the initial medium (g / L): 30 sucrose, NaNO32.0, K2HPO4·3H2O1.0, KCl0.5, MgSO40.5, FeSO4·7H2O0.01. The initial fermentation conditions are: natural pH, inoculum size 10%, liquid volume 50ml / 250ml, 28°C, shaker speed 180r / min, fermentation cycle 48h.

[0072] The effects of fermentation temperature, initial pH, fermentation cycle, inoculum amount, and liquid volume on the degradation rate of AFB1 of CCTCCNO:M2015181 were investigated by single factor experiment.

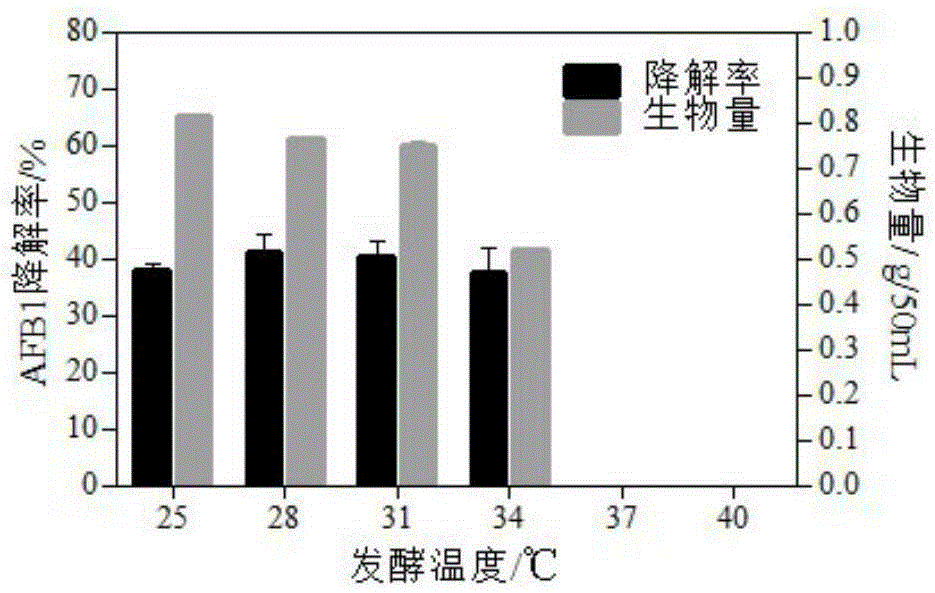

[0073] a. optimal test of fermentation temperature

[0074] according to figure 1 It can be seen that the degradation rate of AFB1 does not change much under the condition of 25-34°C, but it has a greater impact on the biomass, and microorganisms cannot grow under the condition of 37°C and 40°C. In the case of not seriously affecting the gro...

example 3

[0083] Example 3: CCTCCNO: M2015181 medium optimization

[0084] a. Carbon source optimization

[0085] CCTCCNO: M2015181 fermentation medium carbon source optimization results are as follows Figure 7 shown. It can be seen that the AFB1 degradation rate corresponding to most of the carbon sources is very considerable, reaching more than 80%, and the AFB1 degradation rate corresponding to molasses, corncob powder, and corn flour is close to 100%, but the corncob powder group has a certain degree of degradation in the extraction stage. The emulsification phenomenon, for the sake of the rigor of the experiment, this set of data is not considered for the time being. The lowest degradation rate was 50% in the orange peel powder group.

[0086] CCTCCNO:M2015181 can grow well in the fermentation medium of molasses, sodium carboxymethyl cellulose, corn cob powder, and orange peel powder group, which shows that CCTCCNO:M2015181 can utilize these industrial and agricultural by-produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com