Rare earth mine in-situ mine dipping auxiliary leakage device and application method thereof

An in-situ ore leaching and rare earth ore technology, which is applied in the direction of improving process efficiency, can solve the problems of increasing soil slope slippage, shallow well subsidence of liquid injection, and easy seepage of soil layers, so as to reduce the hydraulic gradient and reduce the wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

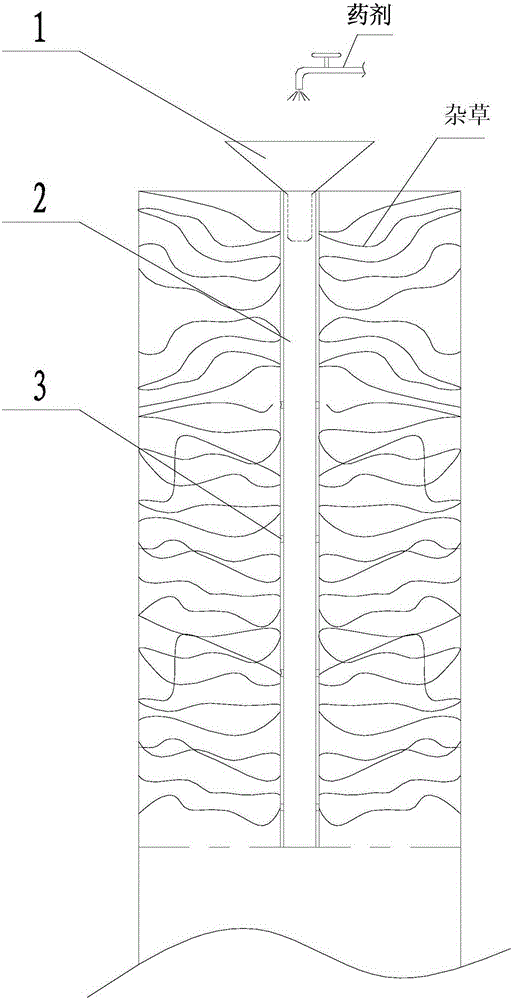

[0016] Such as figure 1 As shown, an auxiliary seepage device for in-situ leaching of rare earth ores includes a liquid inlet hopper 1 and a liquid inlet pipe 2 connected to the liquid inlet hopper 1. The diameter of the liquid inlet pipe 2 is 15-35mm, specifically 15mm , 20mm, 30mm, 35mm, preferably, the diameter of the liquid inlet pipe 2 is 30mm; The length of the tube 2 is 1390 mm, the inlet pipe 2 is provided with small hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com