Device for improving temperature field uniformity of crystal growing furnace of physical vapor transport method

A technology of physical vapor transmission and crystal growth furnace, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as the limitation of temperature gradient distribution uniformity, optimize coil energization mode, reduce axial temperature gradient, The effect of improving the uniformity of the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

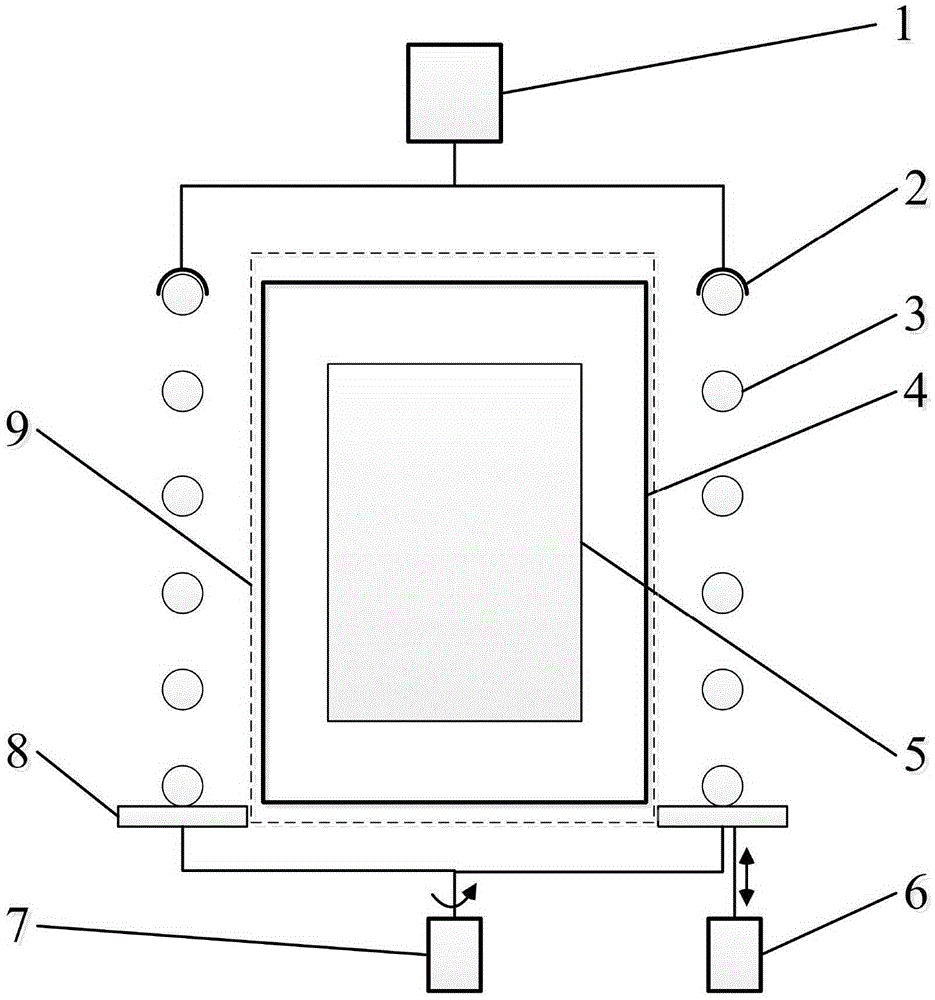

[0023] Such as image 3 and figure 1 As shown, the present embodiment provides a device for improving the temperature field uniformity of the physical vapor transport method crystal growth furnace, including a crystal growth furnace, which includes a radio frequency power supply 1, a contact electrode 2, a coil 3, an insulating layer 4 and graphite The crucible 5, the radio frequency power supply 1 is contact-connected with the coil 3 through the contact electrode 2, an insulation layer 4 is arranged outside the graphite crucible 5, and a coil 3 is wound on the outer side of the insulation layer 4, and the coil 3 is evenly arranged on the insulation layer in a horizontal axis-symmetric manner. Layer 4 outside.

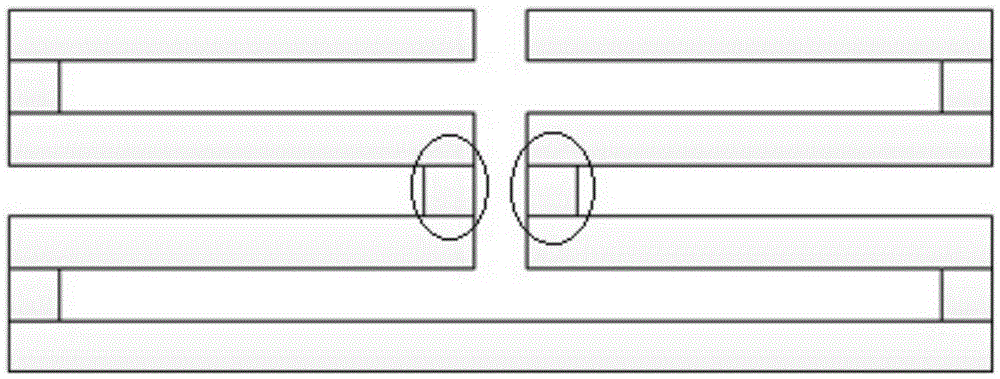

[0024] The number of coils 3 is single, and the single coil is wound on the outside of the insulation layer in a bow-shaped manner. A single coil is wound around the outer half circle of the insulation layer from top to bottom, and then the single coil is wound aroun...

Embodiment 2

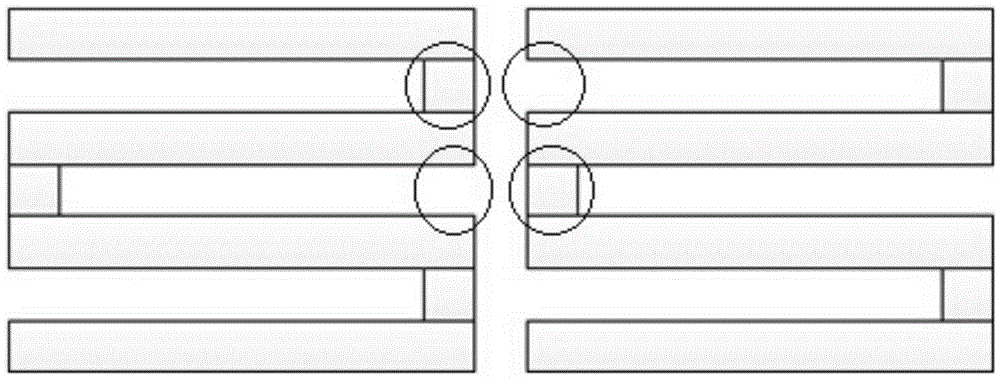

[0029] This embodiment provides a device for improving the temperature field uniformity of the physical vapor transport method crystal growth furnace. The fonts are wound and arranged symmetrically on the outside of the insulation layer 4 . The number of coils can also be three or more, and the specific number of coils is selected according to the size and specification of the growth furnace.

[0030] This embodiment uses two coils, and the bending method of each coil is the same. At the symmetrical center of the two coils, the vacant position of one coil will be supplemented by the other, as image 3 Marked by the middle circle, the temperature in the furnace will be more uniform than that of a single coil; while the expansion diagram of a single coil is center-symmetrical, and the coil bending at the center is relatively concentrated, as shown in figure 2 Marked by the middle circle, this part can cause the temperature of the bending part in the furnace to be too high.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com