Counterweight-variable and hydraulic power-controllable automatic fixed shaft turning plate gate

A hydraulic automatic and flap gate technology, applied in the field of gates, can solve the problems of small gate opening, troublesome management, inflexible gate opening, etc., and achieve the effect of reducing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with embodiment.

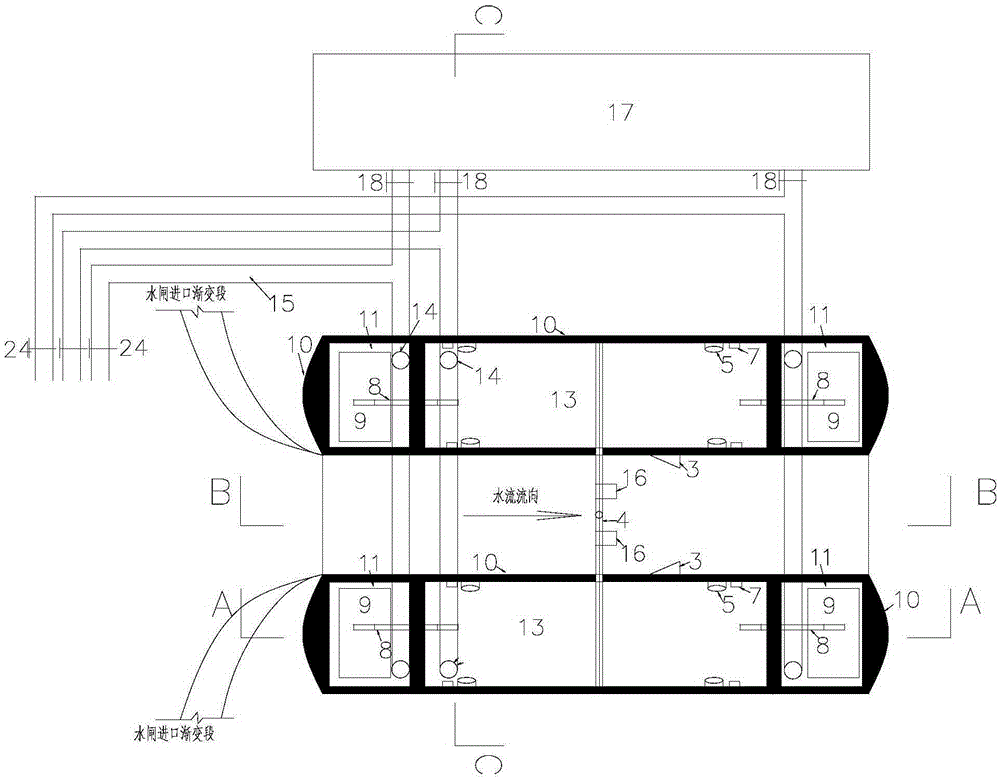

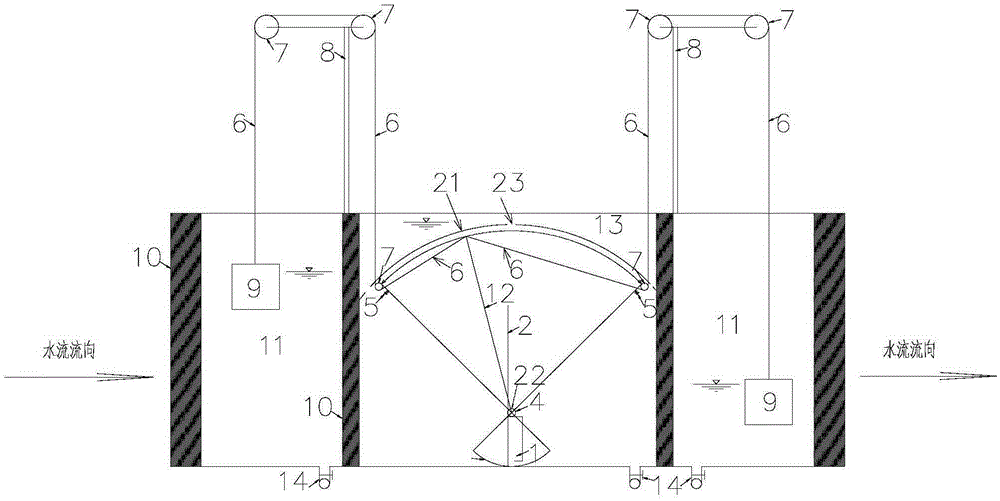

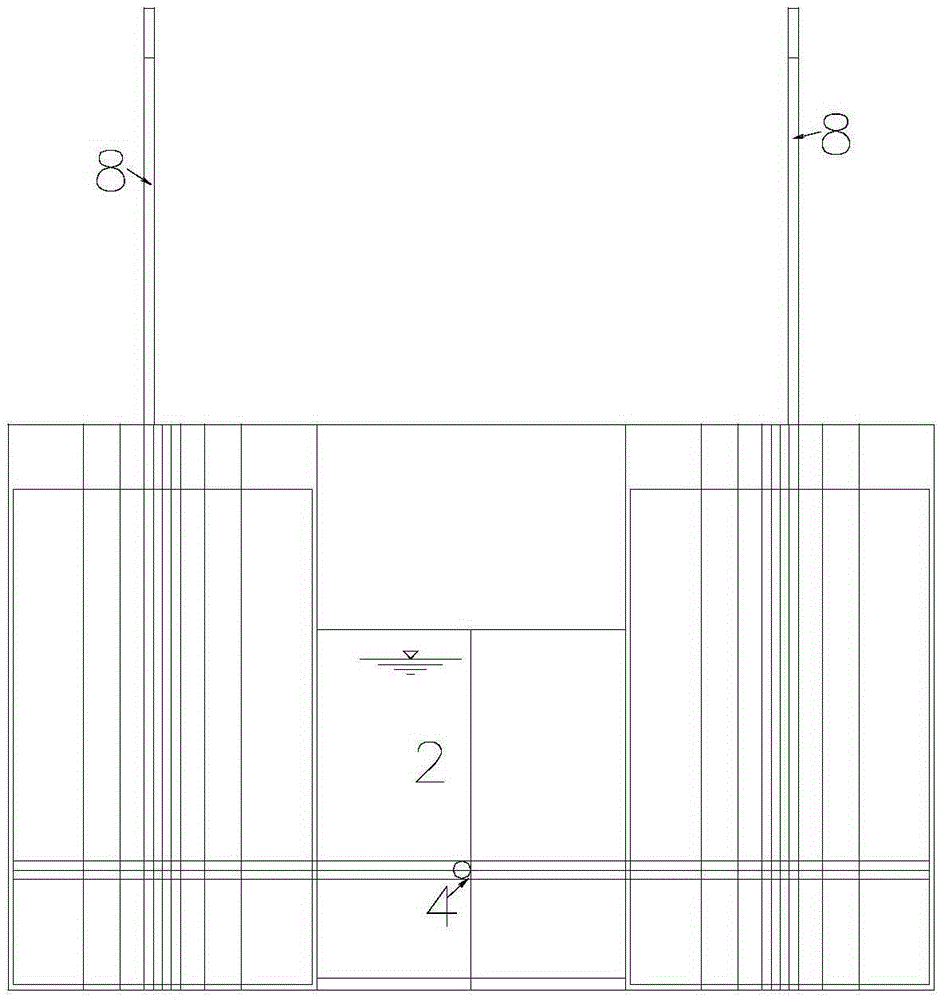

[0032] Such as Figure 1 to Figure 9 As shown, variable counterweight controllable hydraulic automatic fixed axis flap gate, the bottom of the gate 2 is fixed on the rotating shaft 4, the bottom of the backwater surface of the gate 2 is provided with a water tank 1, and the water tank 1 is provided on the side adjacent to the bottom of the gate 2 There is a water hole 19, and a vent hole 20 is provided on the other side. It also includes a gate corbel 3 that restricts the gate 2 from rotating to a horizontal position and supports the gate 2, and a gate that restricts the gate 2 from rotating to a vertical position to support the gate 2. The chamber floor support pier 16 is connected with a buffer device at both ends of the rotating shaft 4 . The buffer device is an empty stomach type gate pier 10, which is composed of a water storage tank 13 and two water collection wells 11 on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com