A method using s‑co 2 Marine diesel engine exhaust waste heat power generation system with orc combined cycle

A technology of marine diesel engine and circulation system, which is applied in the direction of combined combustion mitigation, machine/engine, mechanical equipment, etc., can solve the problem of low energy utilization efficiency of ships, and achieve the effects of improving compactness, reducing compression work, and increasing heat transfer area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

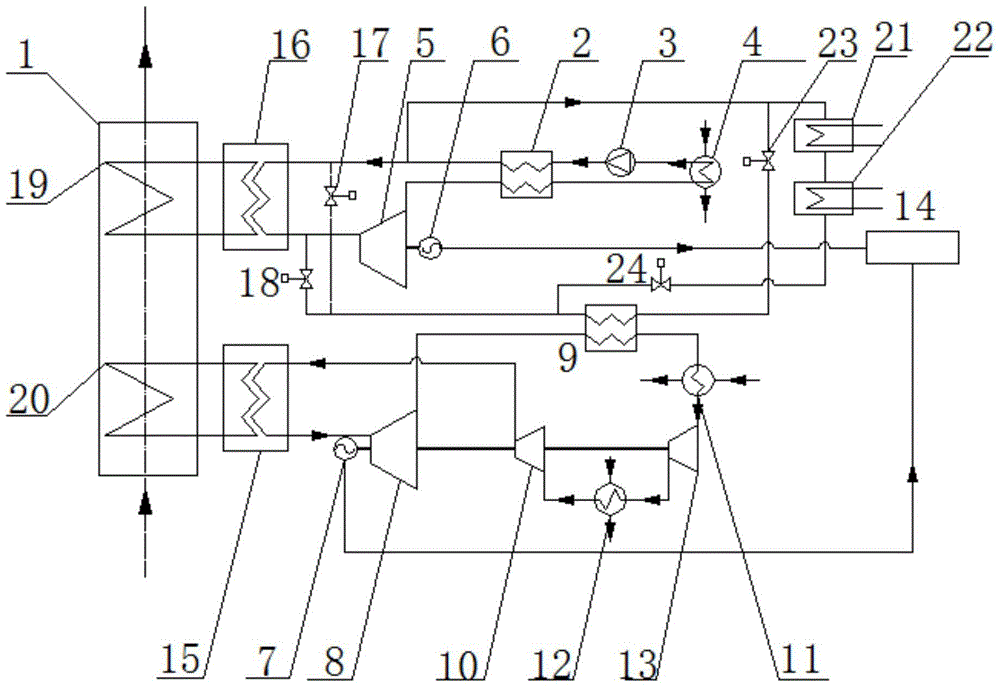

Embodiment approach 1

[0031] The heat exchanger 1 is a finned tube heat exchanger. The diesel engine exhaust enters from the lower end of the heat exchanger and flows out from the upper end. The medium flowing in the tube is heat transfer oil. The internal pipe section of the heat exchanger is divided into two parts, and the upper pipe section is an ORC cycle. The system provides 160°C heat transfer oil as its heat source, and the heat transfer oil transfers heat to the organic working fluid through the heat exchanger 16 of the ORC circulation system. The lower pipe section provides 280°C heat transfer oil as its heat source for the supercritical CO2 cycle system. A critical CO2 cycle system transfers heat to CO2.

[0032] In the supercritical CO2 cycle power generation system, the state point of CO2 entering the first compressor 13 is (31°C, 7.31MPa) and compressed, then cooled to 31°C by seawater again, and enters the second stage compressor 10 for further compression. The CO2 at the outlet of th...

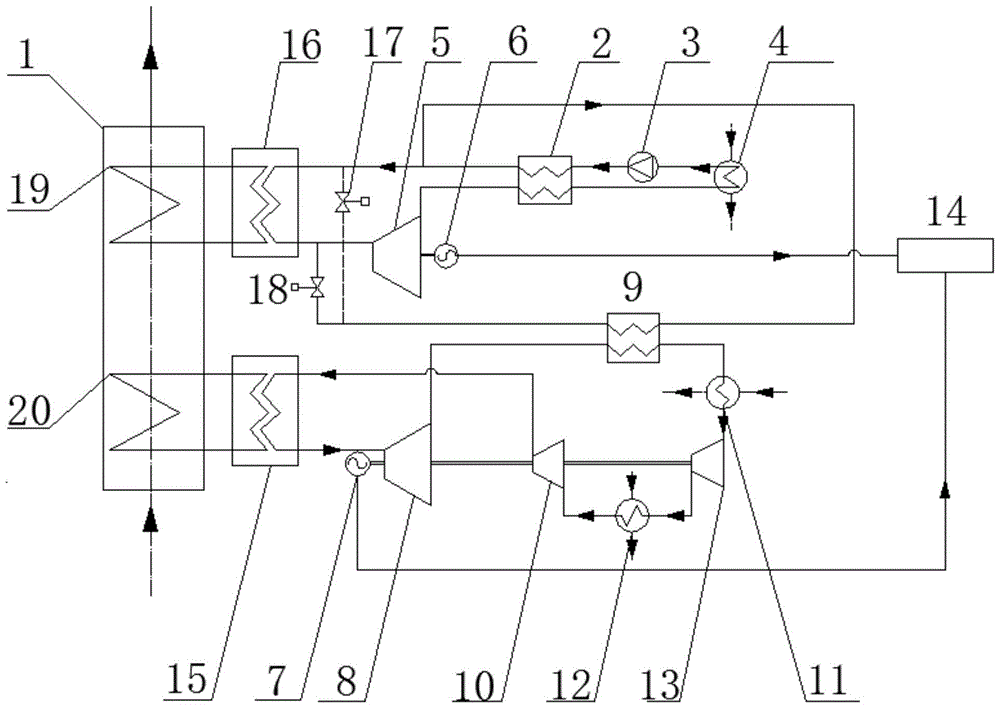

Embodiment approach 2

[0036] The heat exchanger 1 is a finned tube heat exchanger. The diesel engine exhaust enters from the lower end of the heat exchanger and flows out from the upper end. The medium flowing in the tube is heat transfer oil. The internal pipe section of the heat exchanger is divided into two parts, and the upper pipe section is an ORC cycle. The system provides 160°C heat transfer oil as its heat source, and the heat transfer oil transfers heat to the organic working fluid through the heat exchanger 16 of the ORC circulation system. The lower pipe section provides 280°C heat transfer oil as its heat source for the supercritical CO2 cycle system. A critical CO2 cycle system transfers heat to CO2.

[0037] In the supercritical CO2 cycle power generation system, the state point of CO2 entering the compressor 13 is (31°C, 7.31MPa) and then compressed by seawater to cool down to 31°C again, and enter the second stage compressor 10 for further compression. The CO2 at the outlet of the ...

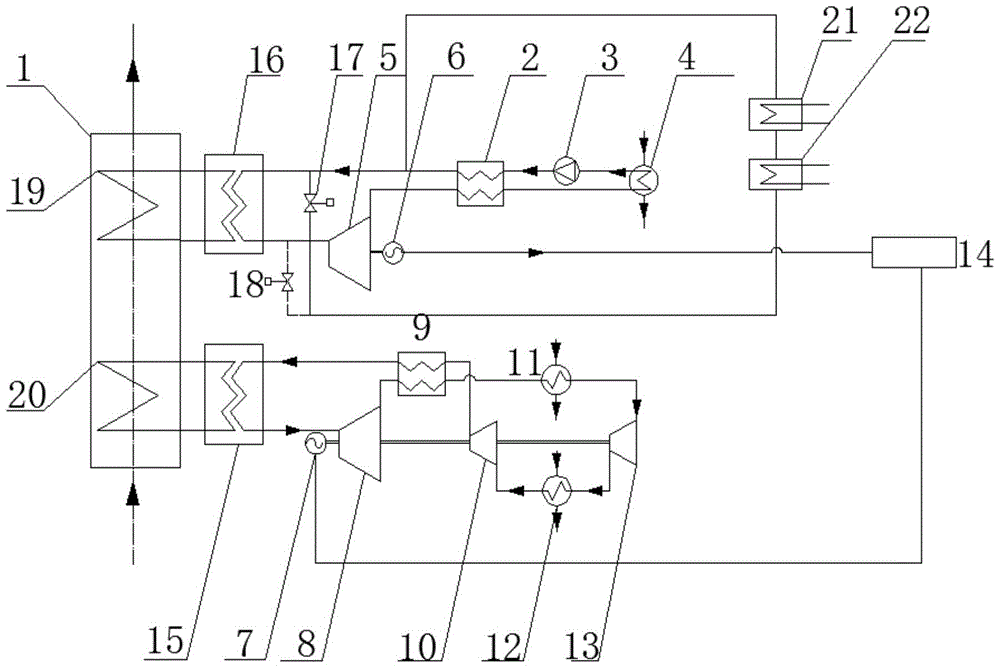

Embodiment approach 3

[0041] Such as image 3 shown. The ORC cycle power generation subsystem and the supercritical CO2 cycle system are independent of each other.

[0042] The heat exchanger 1 is a finned tube heat exchanger. The diesel engine exhaust enters from the lower end of the heat exchanger and flows out from the upper end. The medium flowing in the tube is heat transfer oil. The internal pipe section of the heat exchanger is divided into two parts, and the upper pipe section is an ORC cycle. The system provides 160°C heat transfer oil as its heat source, and the heat transfer oil transfers heat to the organic working fluid through the heat exchanger 16 of the ORC circulation system. The lower pipe section provides 280°C heat transfer oil as its heat source for the supercritical CO2 cycle system. A critical CO2 cycle system transfers heat to CO2.

[0043] In the supercritical CO2 cycle power generation system, the state point of CO2 entering the compressor 13 is (31°C, 7.31MPa) and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com