A Hall thruster anode

A technology of Hall thruster and anode, which is applied in the direction of thrust reverser, machine/engine, and utilization of plasma, etc. It can solve the problems of deposition coating, decrease of anode conductivity, large thermal load, etc., and achieve increased surface area and deposition coating phenomenon Reduction, the effect of heat load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

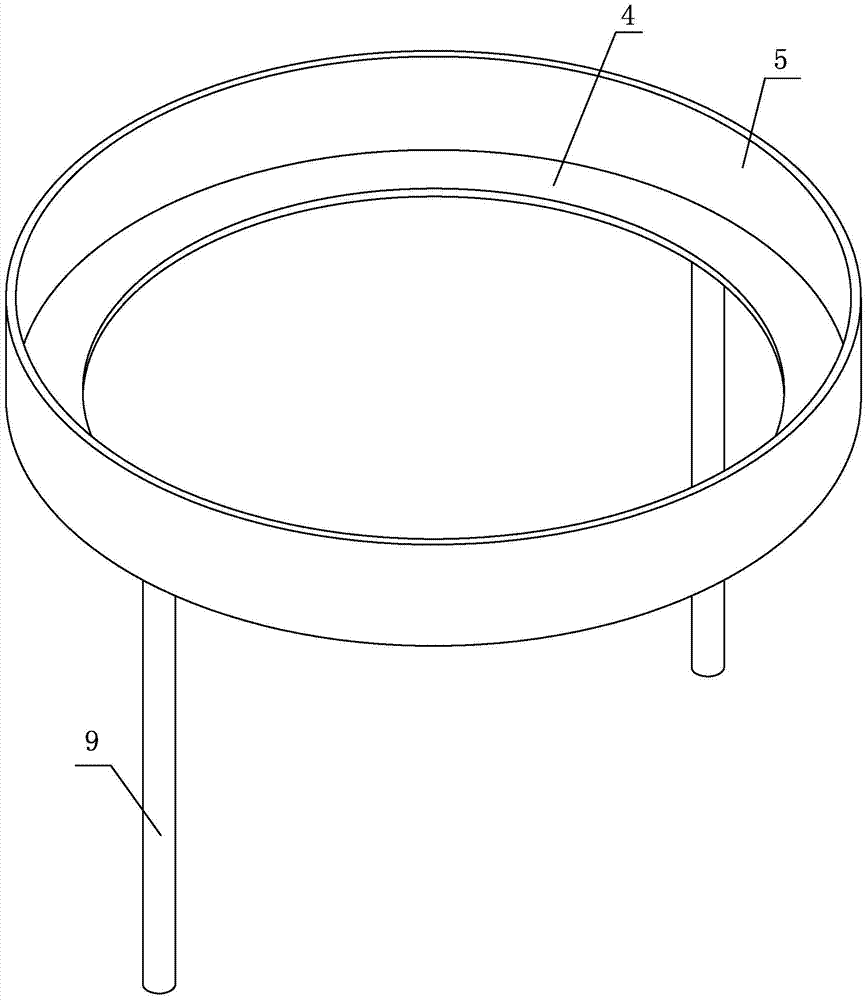

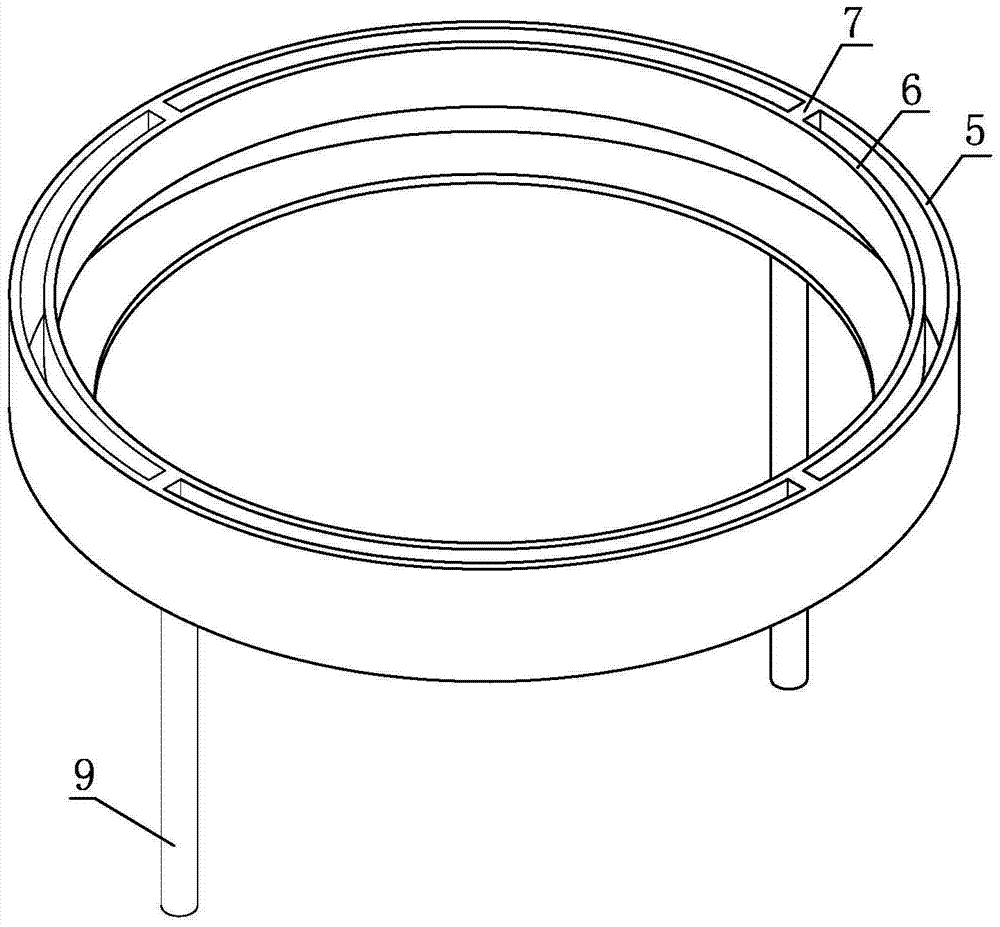

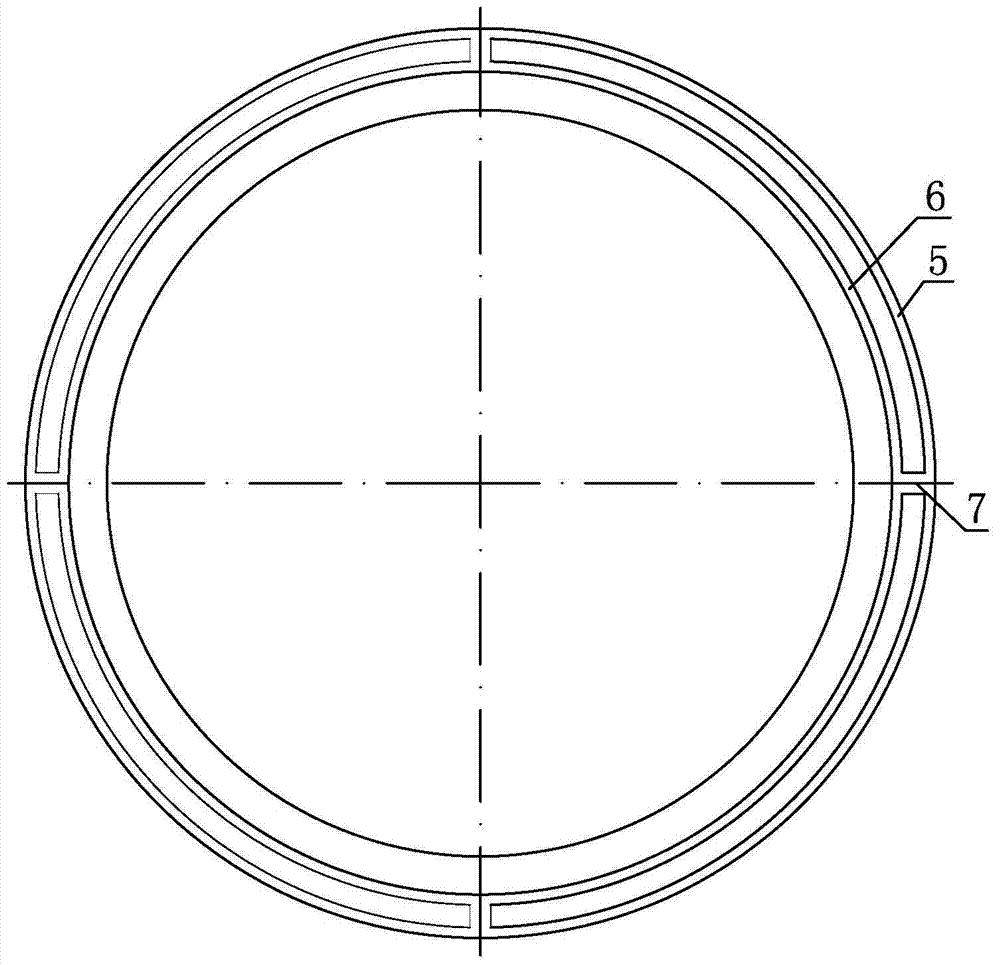

[0008] Specific implementation mode one: combine Figure 2-Figure 5 Explain that a Hall thruster anode in this embodiment includes a bottom ring 4 and a receiving ring 5 connected as one, and it also includes an inner ring 6, and an inner ring 5 having the same shape as the receiving ring 5 is fixed inside the receiving ring 5. The ring 6, the inner ring 6 and the receiving ring 5 form a circular concentric inner and outer double-ring structure, there is a gap between the outer surface of the inner ring 6 and the inner surface of the receiving ring 5, and the inner bottom surface of the inner ring 6 and the bottom ring 4 has a gap. gap.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 2-Figure 5 Note that the upper end surface of the inner ring 6 in this embodiment is flush with the upper end surface of the receiving ring 5 . Such setting ensures that the position of the top of the anode does not exceed the position of the center line of the zero magnetic field zone during use, and the inner surface of the receiving ring 5 and the outer surface of the inner ring 6 can directly receive the magnetic field lines. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 2-Figure 5 Note that the materials of the inner ring 6 and the receiving ring 5 in this embodiment are both metal molybdenum or non-magnetic stainless steel. Such setting, non-magnetic stainless steel material is used for low power, and molybdenum metal material is used for high power, which is beneficial to improve the thermal conductivity of the anode and reduce its own temperature. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com