Spray type flue gas waste heat recycling device

A flue gas waste heat recovery device technology, applied in the direction of climate sustainability, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problems of low proportion of flue gas latent heat recovery, high requirements for equipment anti-corrosion, and measures for flue gas purification , to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

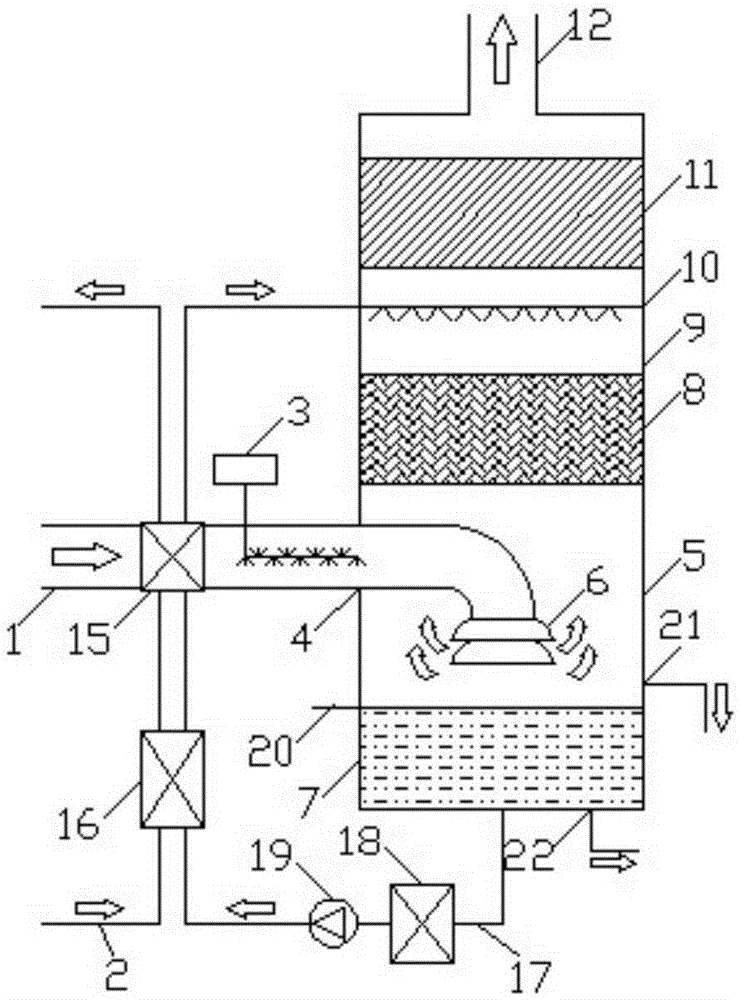

[0027] Such as figure 1 As shown, the spray type flue gas waste heat recovery device provided by the embodiment of the present invention includes a flue gas waste heat deep recovery unit and a flue gas purification unit. The flue gas waste heat deep recovery unit includes a main tower body 5, a first heat exchange 15 and the second heat exchanger 16, the water source is connected to the second heat exchanger 16 through the water inlet pipe 2, the main tower body 5 includes a condensation water collection section 7 and a spray heat exchange section 9, and the flue gas passes through the flue gas The gas pipeline 1 enters the spray heat exchange section 9 to recover the latent heat of the flue gas, and the solution is stored in the condensed water collection section 7 after heat exchange. The first heat exchanger 15 is arranged in the flue gas pipeline 1 for recovering the sensible heat of the flue gas. The condensed water collection section 7 is connected to the second heat ex...

Embodiment 2

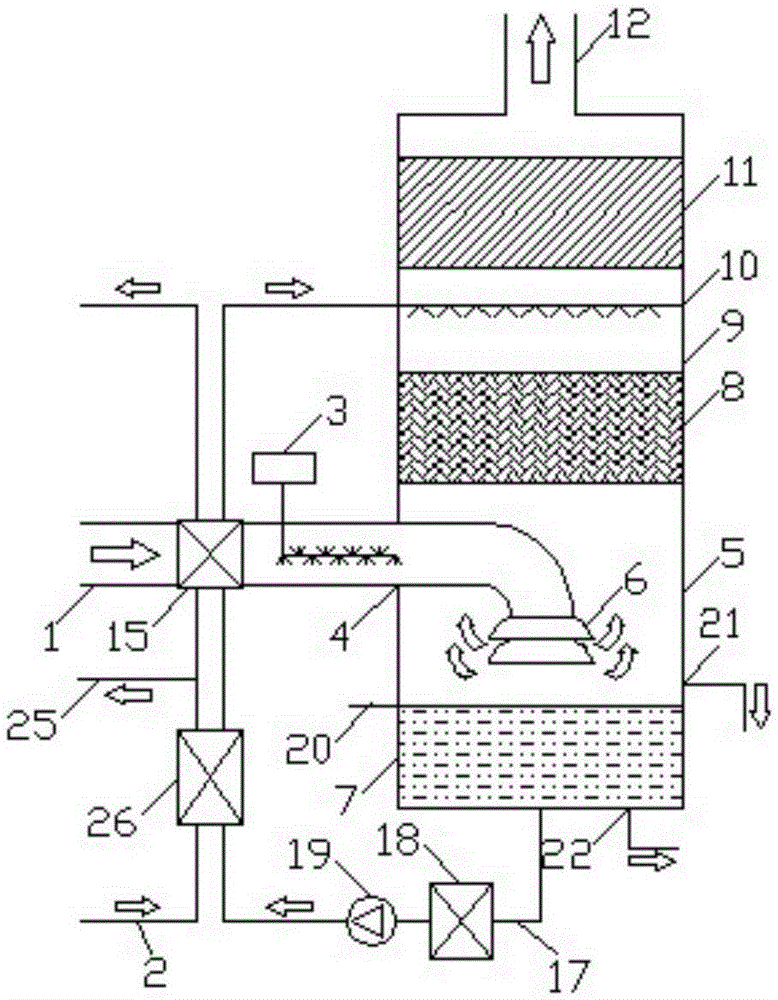

[0038] Since the heating efficiency of the second heat exchanger 16 is not as high as that of the electric heat pump unit 26, the temperature of the hot return water in the water inlet pipe 2 is 40°C. After being heated to 50°C by the second heat exchanger 16, it cannot reach the domestic heat. The supply temperature of the water. In this embodiment, the second heat exchanger 16 is replaced by an electric heat pump unit 26. The flue gas waste heat depth recovery unit includes the main tower body 5, the first heat exchanger 15 and the electric heat pump unit 26. The water source passes through the water inlet pipe 2 respectively Connected with the electric heat pump unit 26 and the first heat exchanger 15, the main tower body 5 includes a condensate collection section 7 and a spray heat exchange section 9, and the flue gas enters the spray heat exchange section through the flue gas pipeline 1 Section 9, the flue gas purification unit includes an oxidation device 3 communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com