A detection method for Al3+ ion produced by early corrosion of aluminum alloy

A detection method and technology of aluminum alloy, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of inability to detect the corrosion process and the exact location of corrosion, expensive instruments, and inconvenient to use, etc. High sensitivity, good linear correlation, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

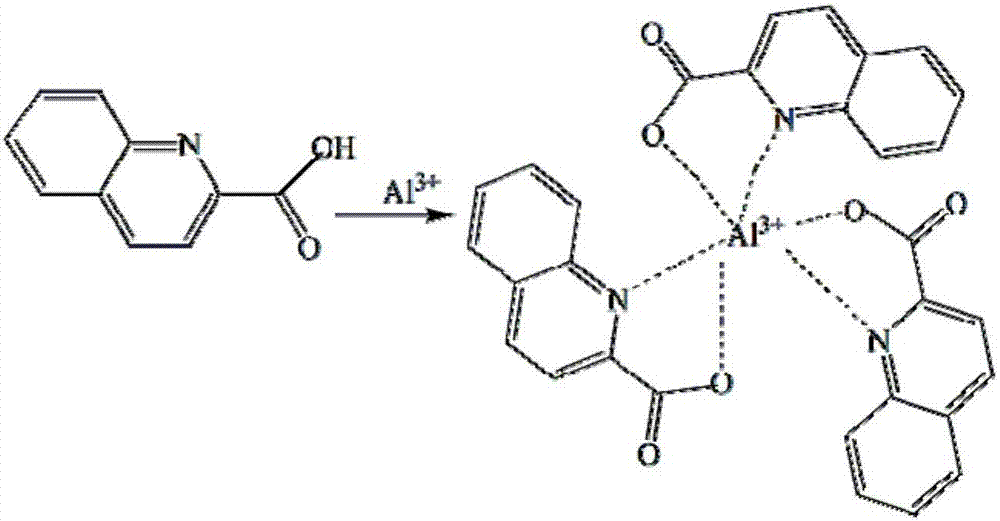

Method used

Image

Examples

Embodiment 1

[0044] Fluorescence detection of aluminum alloy corrosion process:

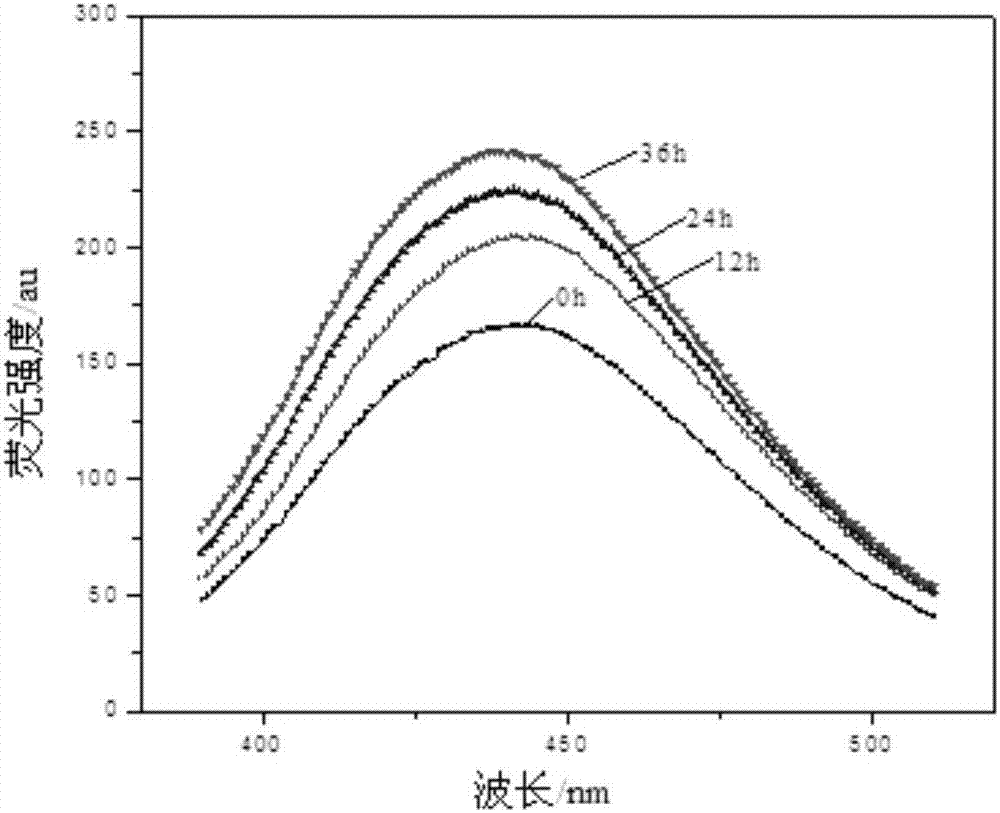

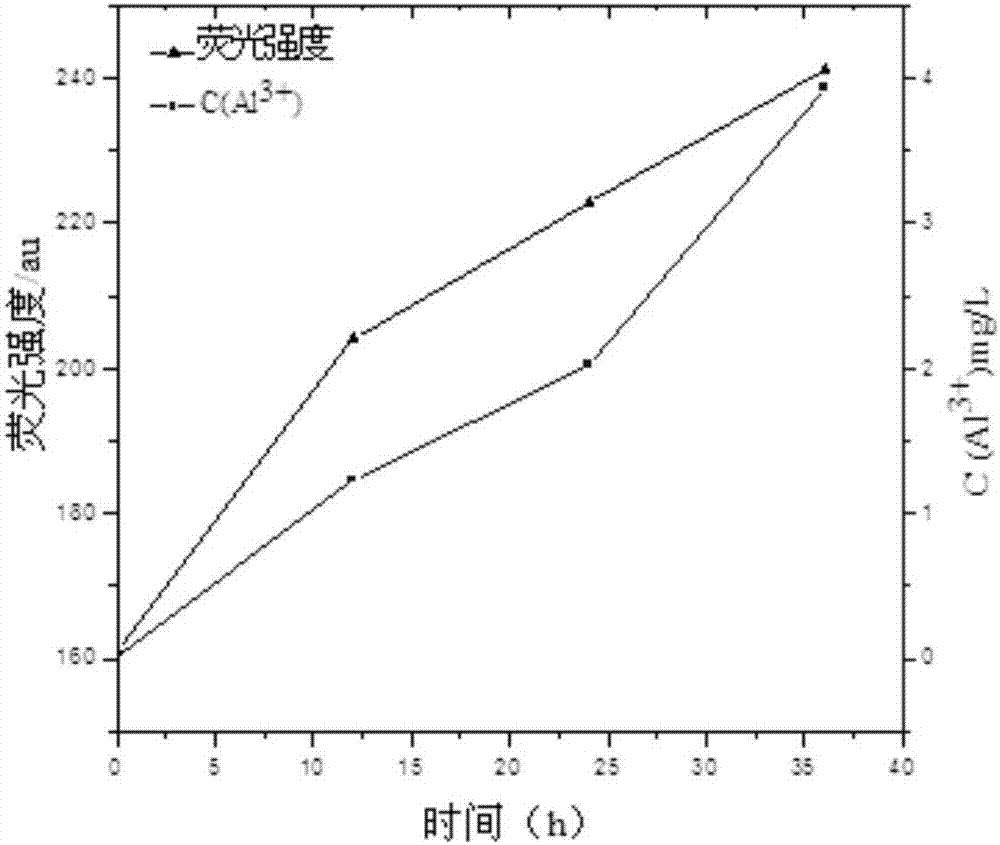

[0045] Polish the cut 5052 aluminum alloy sample step by step with metallographic sandpaper, scrub the surface with alcohol, rinse with deionized water, and blow dry to obtain the aluminum alloy hanging piece, soak the aluminum alloy hanging piece in 200mL containing 0.1g / L quina In the 1wt% NaCl solution of pepicolic acid, pipette 1mL of the corrosion solution into the quartz dish every 12h, and measure the fluorescence spectrum on the RF-5301PC fluorescence spectrometer. see results figure 2 with image 3 .

[0046] from figure 2 , 3 It can be seen that the fluorescence intensity of the solution increases gradually with the prolongation of the soaking time of the coupon. Aluminum alloys containing Cl - Pitting corrosion is extremely prone to occur in the environment, which is due to the Cl in the environment - Uneven adsorption on the passivation film on the aluminum alloy surface leads to uneven c...

Embodiment 2

[0048] Morphological observation of aluminum alloy corrosion process:

[0049] Soak the cut 3cm×5cm×2mm 5052 aluminum alloy sample in 200mL of 1wt% NaCl aqueous solution containing 0.1g / L quinaldicic acid, take it out at regular intervals, and observe it under a stereofluorescence microscope. Corrosion morphology, see the results Figure 5 with Image 6 .

[0050] Such as Figure 5 As shown, before soaking, there were no fluorescent spots on the surface of the coupon; after soaking for 12 hours, small green fluorescent spots began to appear on the surface (due to the black and white drawings, the actual green fluorescent effect cannot be seen in the figure), which shows that the corrosion The oxide film on the surface of the aluminum alloy coupons in the liquid is in the Cl - Under corrosion, the aluminum alloy coupons are cracked, and the aluminum alloy coupons are pitted. At this time, the cracking and repair of the passivation film are carried out at the same time, and ...

Embodiment 3

[0053] Inductively Coupled Plasma Emission Spectroscopy Detection

[0054] Three pieces of AA5052 aluminum alloys of 3cm×5cm×2mm were polished step by step to the mirror surface with 400, 800 and 1200 mesh metallographic sandpaper, degreased with ethanol, rinsed with deionized water, dried with cold wind, soaked in 200mL containing 0.1g / L quinolone Soak in 1wt% NaCl aqueous solution of nacidic acid for 0h, 12h, 24h, 36h respectively. The experimental temperature was 25°C. After the solution is cooled to room temperature, take 100ml of the supernatant to a 100ml volumetric flask, shake it up and test it. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com