Intelligent control system and method of bunker network

A technology of control system and network intelligence, applied in the field of silos, can solve the problems of full material, rushing out of the silo, and no warning of material level, etc., to eliminate the danger of filling into the wrong silo, avoid the risk of environmental pollution, and improve Effects of Life and Availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

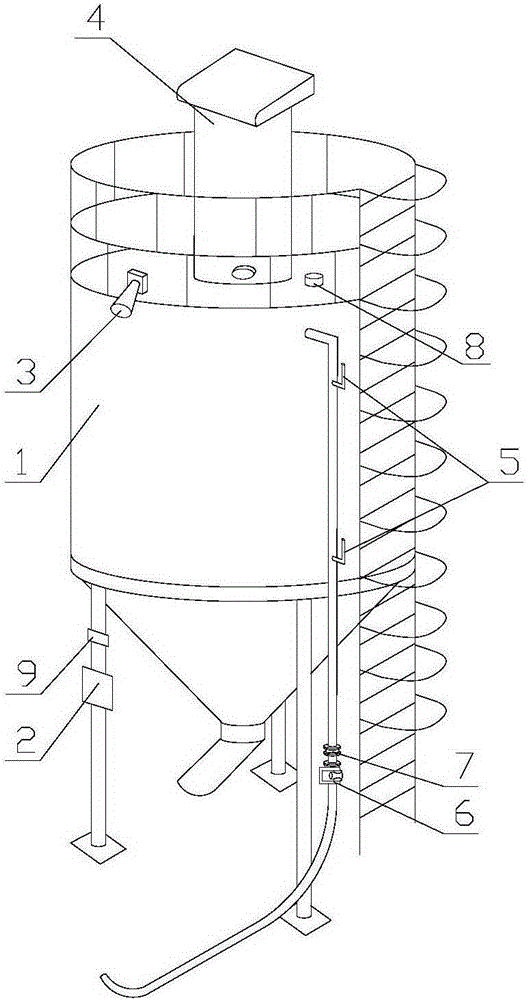

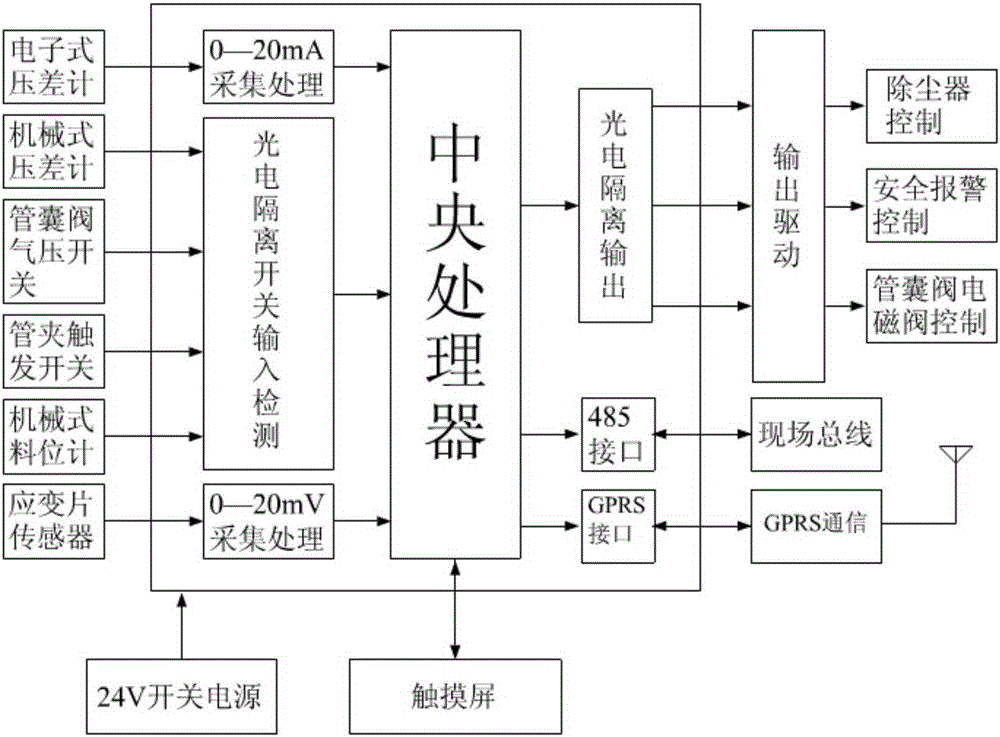

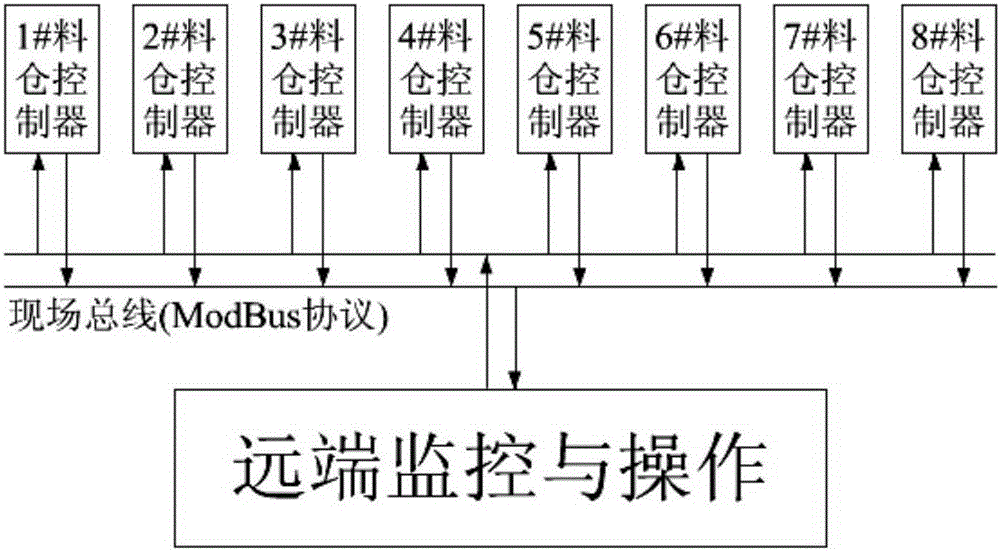

[0034] See Figure 1-Figure 9 , the silo network intelligent control system, the silo is connected with a pipe bag, and the pipe bag is equipped with a pipe bag valve and a pipe clip, including an electronic differential pressure gauge, a mechanical differential pressure gauge, a pressure switch of the pipe bag valve, and a pipe clip trigger Switches, mechanical level gauges, strain gauge sensors, strain gauge level gauges, silo safety controllers, mechanical differential pressure gauges, and electronic differential pressure gauges are all set on the top of the silo, and the air pressure switch of the bladder valve is used to control The pipe bag valve and the pipe clamp trigger switch control the pipe clamp. The mechanical material level gauge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com