Wireless remote control microinjection device

A micro-injection, wireless remote control technology, applied in the direction of using electric device flow control, etc., can solve the problems of difficult to achieve networking and intelligence, complex manufacturing process, high price, etc., to achieve intelligent and networking, and simple control methods. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

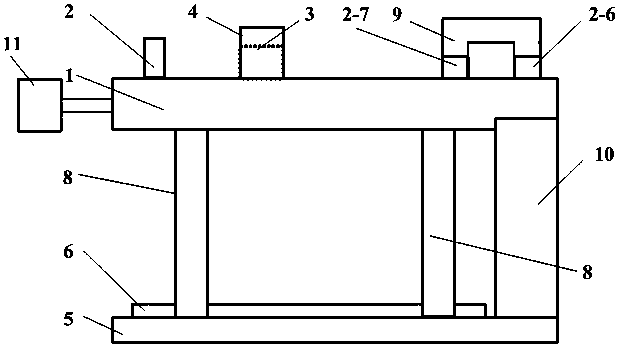

[0019] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, the wireless remote control micro-injection device described in this embodiment includes a liquid generating device 10, an air pressure source 11, a structural layer and a control layer; the air pressure source 11 provides gas for the structural layer; the structural layer and the control layer can be arranged up and down , connected by four supporting columns 8, the liquid generating device 10 is arranged between the structural layer and the control layer; the liquid generating device 10 is used to output the liquid for injection;

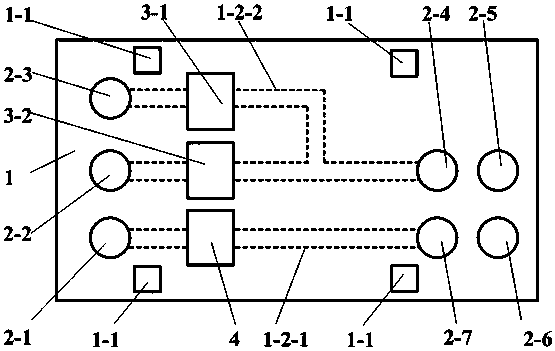

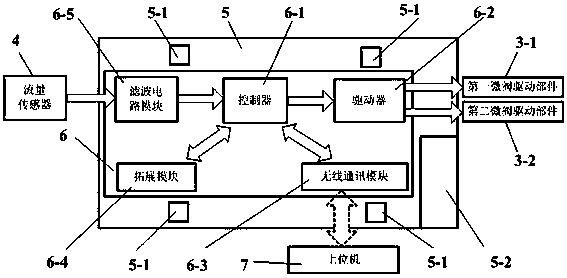

[0020] The structural layer includes a flow channel and base packaging module 1, a flow channel external joint 2, a microvalve drive unit 3, a flow sensor 4 and a hose 9; the flow channel and base packaging module 1 includes four support column installation holes 1 -1. Micro flow channel 1-2, concave film 1-3, flat film 1-4, flow chan...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Image 6 Referring to this embodiment, the liquid to be transported 10-5 in the wireless remote control micro-injection device can be medicine, nutrients, biological reagents, chemical reagents or water. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 with Figure 4 To illustrate this embodiment, the air pressure source 11 in the wireless remote control microinjection device can be a micro air pump, an air pump, an air compressor or a nitrogen tank. Other connection relationships are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com