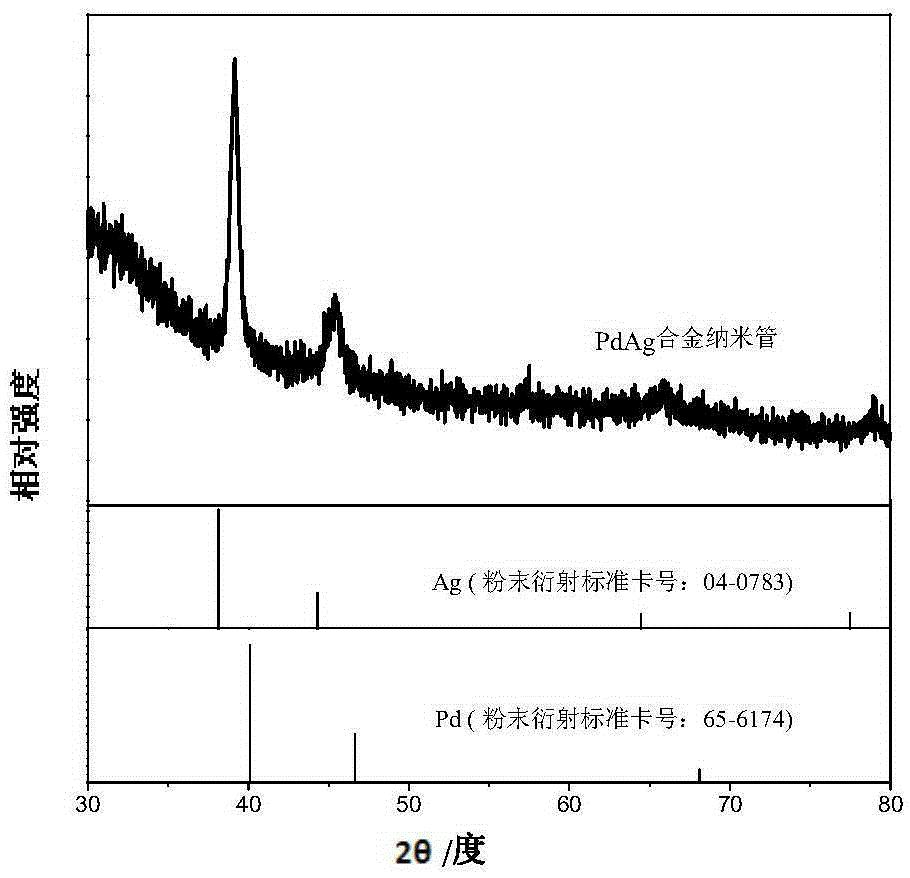

PdAg alloy nanotube positive catalyst of direct direct ethanol fuel cell and preparation method of PdAg alloy nanotube positive catalyst

A technology of alloy nanometer and catalyst, applied in the field of electrochemistry, can solve the problems such as the preparation method of PdAg alloy nanotube direct ethanol fuel cell anode catalyst, and achieve the effect of performance improvement, simple greenness, cost reduction, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

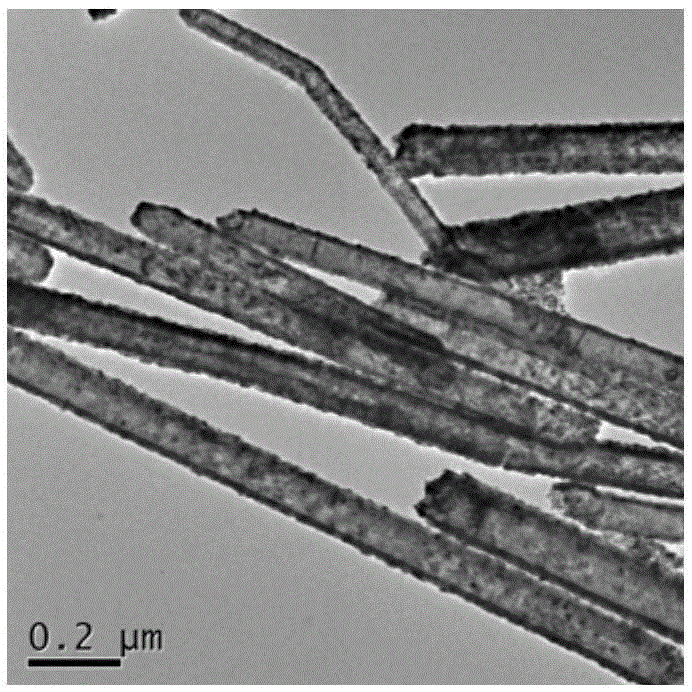

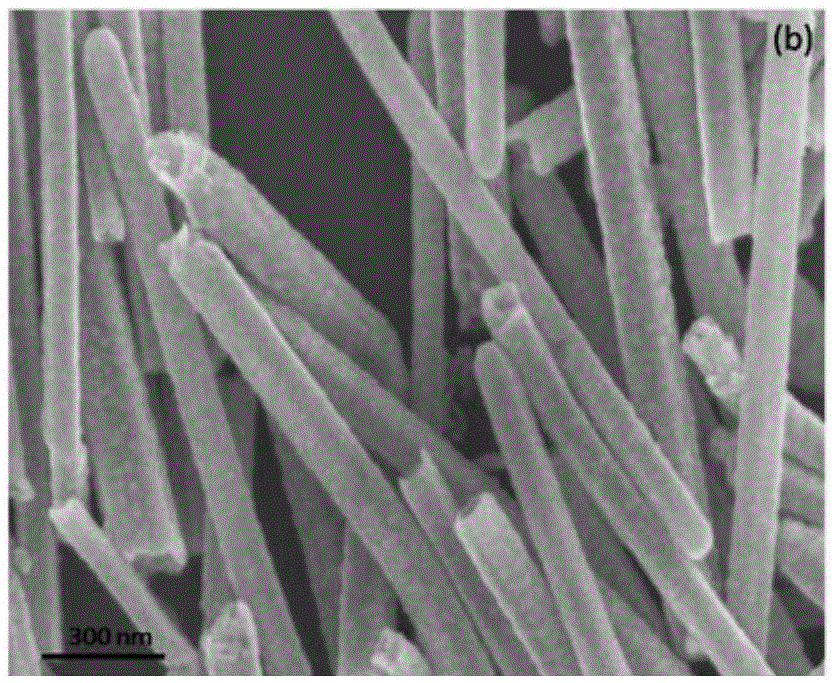

Embodiment 1

[0036] A) Using ethylene glycol as a solvent, prepare 0.3M PVP solution and 0.1M AgNO 3 solution and 20mM sodium chloride in ethylene glycol solution; using deionized water as solvent, prepare saturated aqueous sodium chloride solution and 0.564mM PdCl 2 solution;

[0037] B) Mix 2.5mL of ethylene glycol and 0.11mL of sodium chloride in ethylene glycol and stir at 160°C for 1h, then add 0.2mL of 0.1MAgNO 3 The solution was evenly added dropwise and the dropwise addition was completed within two minutes, and then 2.03mL of 0.1MAgNO was added dropwise at the same time. 3 solution and 2.23mL of 0.3MPVP solution were evenly added dropwise within five minutes;

[0038]C) stirring the solution obtained in step B) at 160° C. for 45 minutes, and cooling at room temperature to obtain silver nanowires;

[0039] D) Add 40 ml of deionized water to the solution containing silver nanowires obtained in step C), and then add 100 ml of freshly prepared PdCl in step A) dropwise at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com