Preparation method of navel orange effervescent tablets

A technology for effervescent tablets and navel oranges, applied in the field of deep processing of agricultural products, can solve the problems of rough processing methods and not many production process examples, and achieve the effects of preventing rupture and bleeding, enhancing toughness and promoting the absorption of Vc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

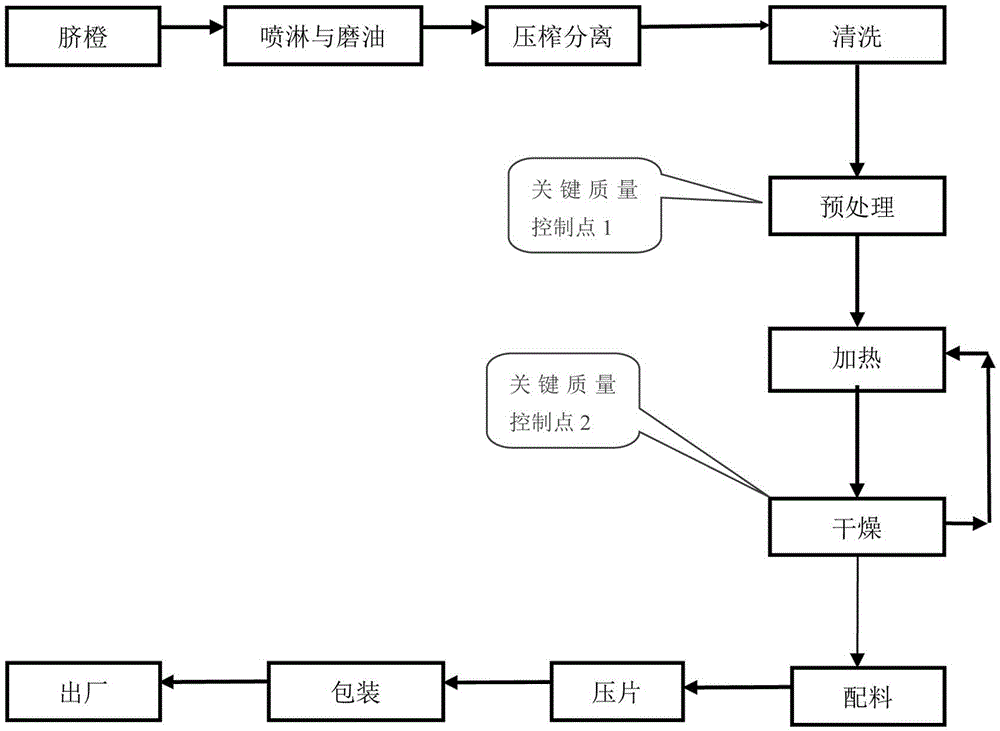

Image

Examples

Embodiment 1

[0019] Peeling: Clean the fresh navel oranges, squeeze out the juice, then peel off the peel and pulp and store them separately.

[0020] Pretreatment: Wash the orange peel, put it in an oven and bake at 35°C for 48 hours, and control the moisture in the orange peel to 13%. Then pulverize and process to make orange peel powder. The pulp is put into an oven at 45°C and blasted for 72 hours, and crushed to make orange pulp powder.

[0021] Heating: put the orange peel powder in boiling water and boil for 30 minutes, and filter with a cardboard when the liquid temperature is 75°C. Care should be taken to prevent impurities from being mixed in during processing.

[0022] Drying: Freeze the supernatant at -4~0°C for 24 hours, and obtain crude hesperidin powder through the purification step of freeze-drying.

[0023] Purification: Dissolve the crude hesperidin powder in hot water, repeat the process of heating, filtering, freezing and drying, and finally the purity of hesperidin ...

Embodiment 2

[0027] Peeling: Clean the fresh navel oranges, grind them for oil, squeeze out the juice, then peel off the peel and pulp, and store them separately.

[0028] Pretreatment: Wash the orange peel, put it in an oven and bake at 40°C for 36 hours, and control the moisture in the orange peel to 10%. Then pulverize and process to make orange peel powder. The pulp is put into an oven at 45°C and blasted for 72 hours, and crushed to make orange pulp powder.

[0029] Heating: Put the orange peel powder into boiling water and cook for 30 minutes, and filter with a cardboard when the liquid temperature is 70°C. Care should be taken to prevent impurities from being mixed in during processing.

[0030] Drying: Freeze the supernatant at -4~0°C for 24 hours, and obtain crude hesperidin powder through the purification step of freeze-drying.

[0031] Purification: Dissolve the crude hesperidin powder in hot water, repeat the process of heating, filtering, freezing and drying, and finally th...

Embodiment 3

[0035] Peeling: Clean the fresh navel oranges, grind them for oil, squeeze out the juice, then peel off the peel and pulp, and store them separately.

[0036] Pretreatment: Wash the orange peel, put it in an oven and bake at 45°C for 24 hours, and control the moisture in the orange peel to 8%. Then pulverize and process to make orange peel powder. The pulp is put into an oven at 45°C and blasted for 72 hours, and crushed to make orange pulp powder.

[0037] Heating: Put the orange peel powder in boiling water and boil for 30 minutes, and filter with a cardboard when the liquid temperature is 65°C. Care should be taken to prevent impurities from being mixed in during processing.

[0038] Drying: Freeze the supernatant at -4~0°C for 24 hours, and obtain crude hesperidin powder through the purification step of freeze-drying.

[0039] Purification: Dissolve the crude hesperidin powder in hot water, repeat the process of heating, filtering, freezing and drying, and finally the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com