A preparation method of organic/inorganic hybrid double-layer nano-film self-rolling tube

A nano-membrane and inorganic technology, which is applied in the field of preparation of organic/inorganic hybrid double-layer nano-membrane self-rolling tubes, can solve problems such as deficiencies, limited applications, and non-degradable inorganic materials, and achieves mild conditions, simple size control, and easy preparation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

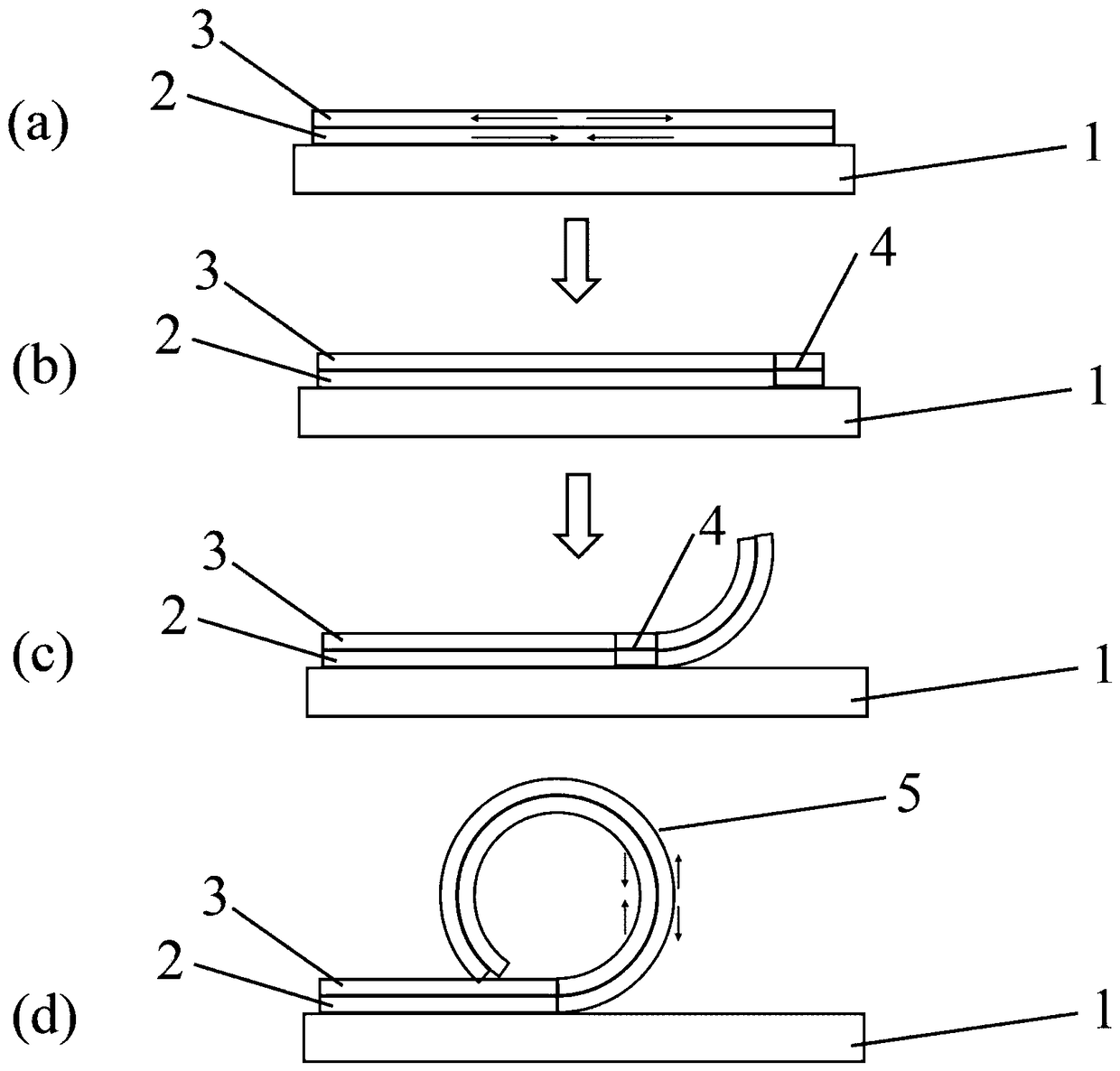

Method used

Image

Examples

Embodiment 1

[0031] A. Grinding and polishing the magnesium sheet, cleaning with ethanol, cleaning with pickling solution, and then vacuum drying; the pickling solution is HNO 3 , Mg(NO 3 ) 2 and ethanol mixed solution, HNO in the mixed solution 3 The concentration is 20g / L, Mg(NO 3 ) 2 The concentration of ethanol is 150g / L, and the concentration of ethanol is 300g / L.

[0032] B. Place the magnesium sheet obtained in step A in a NaOH solution with a concentration of 3.0mol / L, and react for 3.5h at 60°C to obtain inorganic Mg(OH) on the surface of the magnesium sheet 2 film;

[0033] C, preparation concentration is the phytic acid solution of 5mg / mL, then the pH value of phytic acid solution is adjusted to 5;

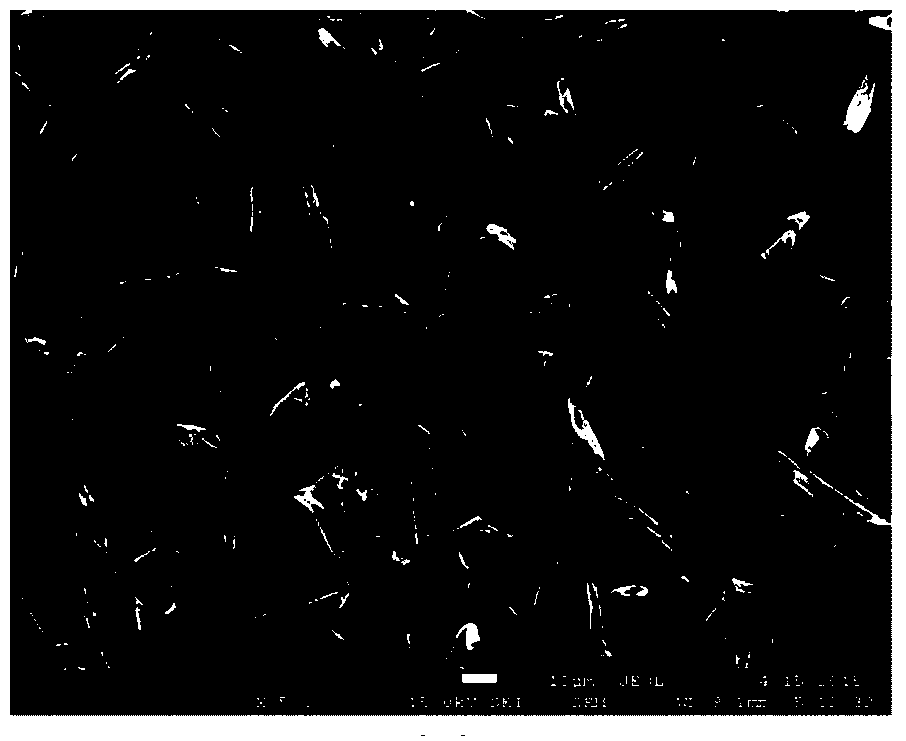

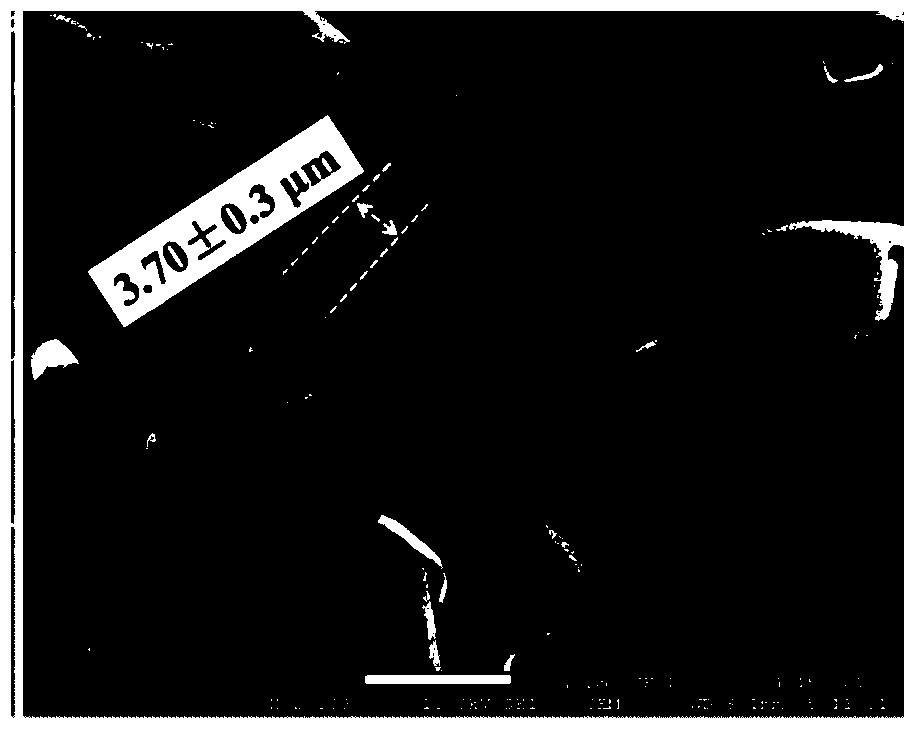

[0034] D, place the magnesium flakes processed in the B step in the phytic acid solution obtained in the C step, let it stand for 10 minutes, and the phytic acid is deposited on the inorganic Mg(OH) 2 On the thin film, that is, an organic / inorganic hybrid double-layer nano-fi...

Embodiment 2

[0039] A method for preparing an organic / inorganic hybrid double-layer nano-membrane self-rolling tube, the specific steps of which are:

[0040] A. Grinding and polishing the magnesium sheet, cleaning with ethanol, cleaning with pickling solution, and then vacuum drying; the pickling solution is HNO 3 , Mg(NO 3 ) 2 and ethanol mixed solution, HNO in the mixed solution 3 The concentration is 22g / L, Mg(NO 3 ) 2 The concentration of ethanol is 140g / L, and the concentration of ethanol is 320g / L.

[0041] B. Place the magnesium sheet obtained in step A in a NaOH solution with a concentration of 2.5mol / L, and react for 4 hours at 70°C to obtain inorganic Mg(OH) on the surface of the magnesium sheet 2 film;

[0042] C. Prepare a phytic acid solution with a concentration of 6 mg / mL, and then adjust the pH value of the phytic acid solution to 6;

[0043] D, place the magnesium flakes processed in the B step in the phytic acid solution obtained in the C step, let it stand for 5 mi...

Embodiment 3

[0046] A method for preparing an organic / inorganic hybrid double-layer nano-membrane self-rolling tube, the specific steps of which are:

[0047] A. Grinding and polishing the magnesium sheet, cleaning with ethanol, cleaning with pickling solution, and then vacuum drying; the pickling solution is HNO 3 , Mg(NO 3 ) 2 and ethanol mixed solution, HNO in the mixed solution 3 The concentration is 25g / L, Mg(NO 3 ) 2 The concentration of ethanol is 160g / L, and the concentration of ethanol is 280g / L.

[0048] B. Place the magnesium sheet obtained in step A in a NaOH solution with a concentration of 3.5mol / L, and react for 3 hours at 50°C to obtain inorganic Mg(OH) on the surface of the magnesium sheet 2 film;

[0049] C. Prepare a phytic acid solution with a concentration of 4 mg / mL, and then adjust the pH value of the phytic acid solution to 5.5;

[0050] D, place the magnesium flakes processed in step B in the phytic acid solution obtained in step C, let it stand for 30min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com