Novel silicon carbide two-layer wear-resistant steel pipe

A technology of wear-resistant steel pipe and silicon carbide, which is applied in the field of wear-resistant bent pipe, can solve the problems of low cost and poor wear resistance, and achieve the effect of moderate cost, stable geometric size and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

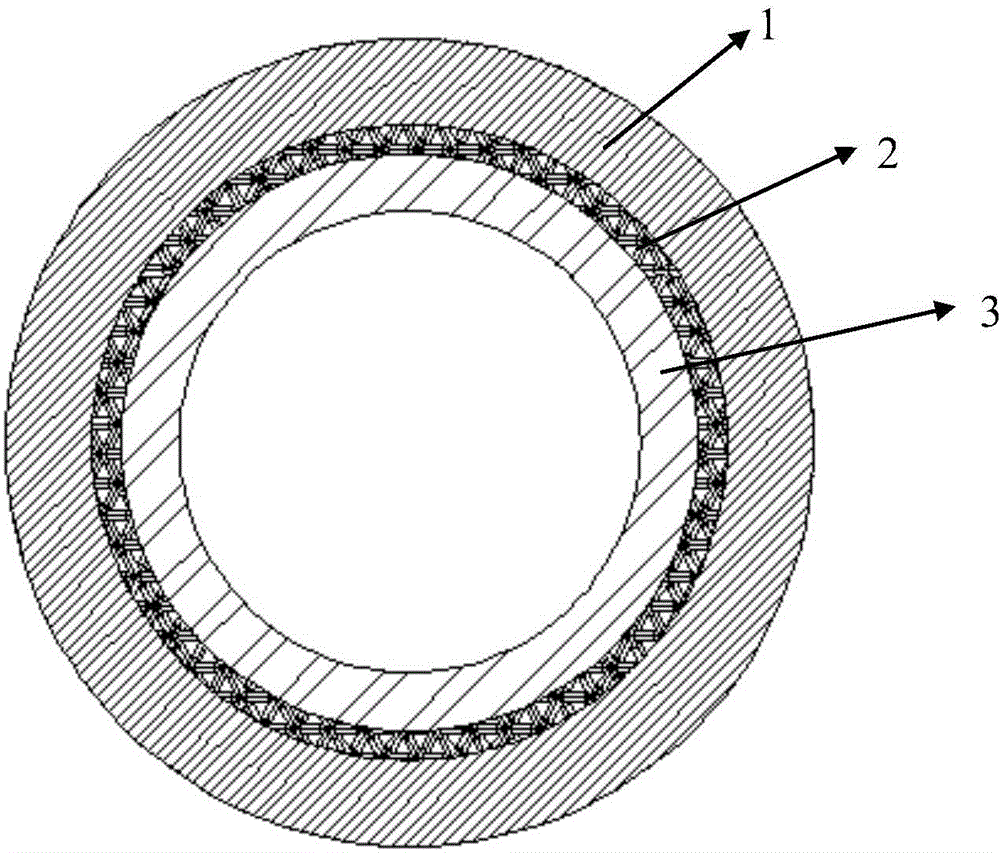

[0019] A new type of silicon carbide double-layer wear-resistant steel pipe, including an outer shell layer 1, an inner lining layer 3 and a filling layer 2. The filling layer is the gap between the outer shell layer 1 and the inner lining layer 3. First, the sintered silicon carbide is processed into a cylinder Shaped inner lining layer, the outer shell layer is processed by A3 steel pipe, the shape is the same as the inner lining layer, the inner diameter of the outer shell layer is slightly larger than the outer diameter of the inner lining layer, and the sintered silicon carbide cylinder is placed on the processed A3 steel pipe bend Inside the tube, the gaps are filled with wear-resistant ceramic powder to form a filling layer, and the surface hardness of silicon carbide lining is 90 HRC.

Embodiment 2

[0021] A new type of silicon carbide double-layer wear-resistant steel pipe, including an outer shell layer 1, an inner lining layer 3 and a filling layer 2. The filling layer is the gap between the outer shell layer 1 and the inner lining layer 3. First, the sintered silicon carbide is processed into a cylinder Shaped inner lining layer, the outer shell layer is processed by A3 steel pipe, the shape is the same as the inner lining layer, the inner diameter of the outer shell layer is slightly larger than the outer diameter of the inner lining layer, and the sintered silicon carbide cylinder is placed on the processed A3 steel pipe bend Inside the pipe, the gaps are filled with wear-resistant ceramic cement to form a filling layer, and the surface hardness of silicon carbide lining is 80 HRC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com