Intelligent unmanned sowing aerial vehicle

An unmanned aerial vehicle and intelligent technology, applied in the direction of motor vehicles, aircraft control, aircraft parts, etc., can solve the problems of short continuous operation time, inability to accurately control the sowing height, key parameters of the sowing line and the amount of sowing, and high risk of testing. , to achieve the effect of reducing input and maintenance costs, saving time to return to dosing, simple structure and control principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

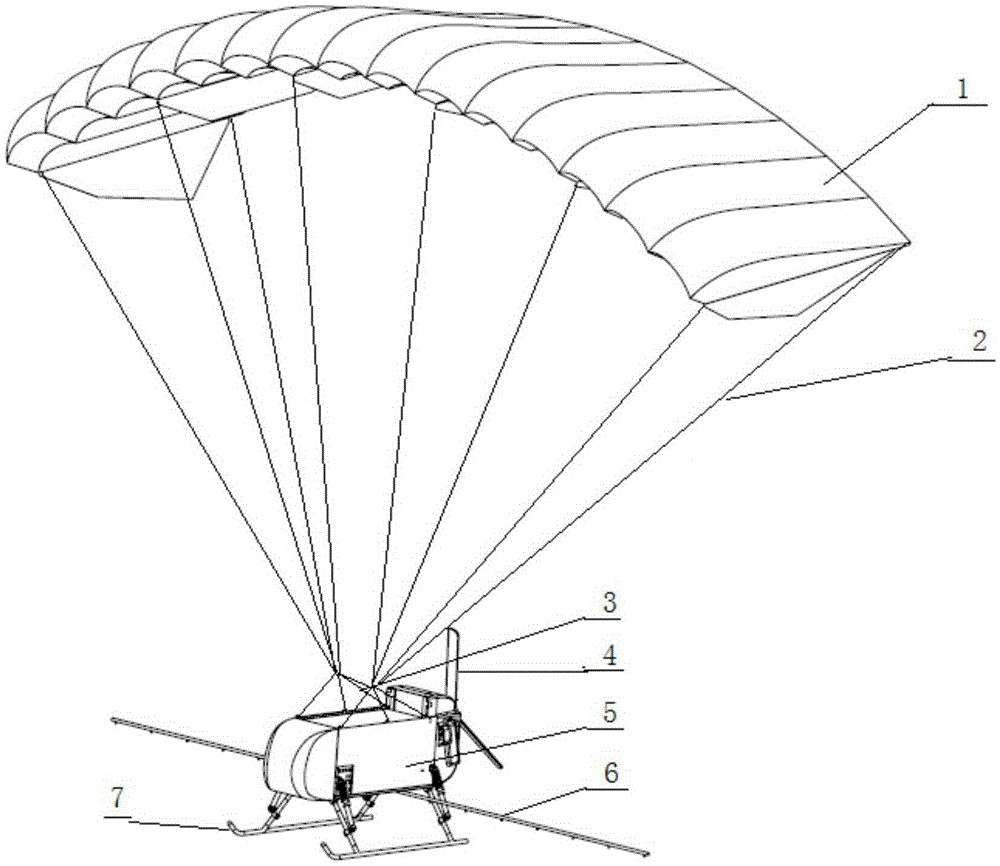

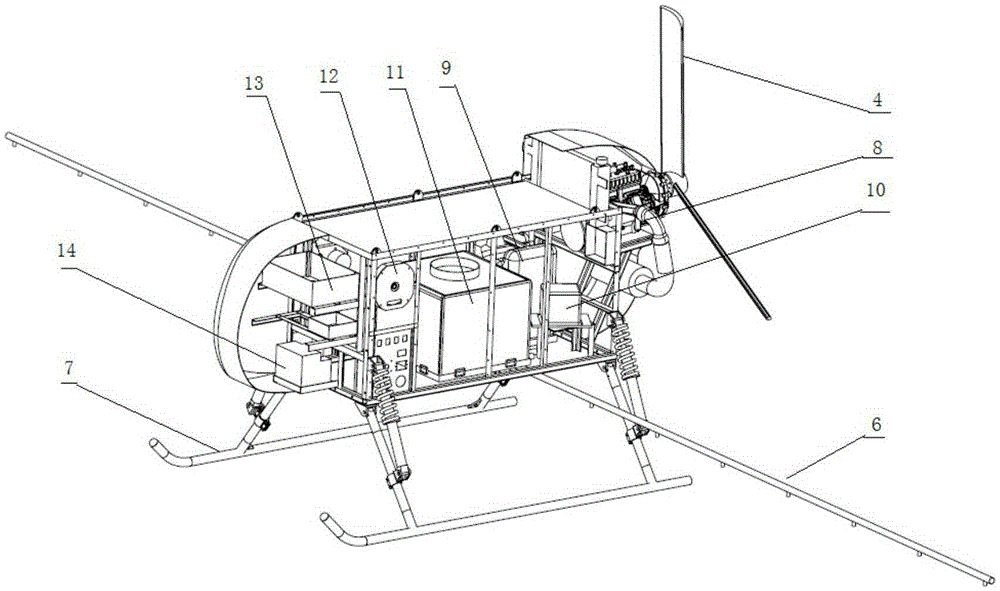

[0037] The unmanned aerial vehicle comprises a parafoil 1, a control rope 2, a suspension belt 3, a propeller 4, an engine 8, a body 5, a spray bar 6 and a landing gear 7. The parafoil 1 is used as a wing and is connected with the body 5 through the suspending belt 3 to provide lift for the soft-wing unmanned aerial vehicle. The propeller 4 is installed on the engine 8, and the engine 8 is fixed on the rear part of the soft-wing UAV body 5. The fuel provided by the fuel tank 9 is converted into the power output of the engine 8 to propel the soft-wing UAV to move forward, and the soft-wing UAV is controlled by the power. The flying height of the wing drone. The landing gear 7 is a skid-type landing gear, which provides landing support for the take-off and landing of the soft-wing unmanned aerial vehicle.

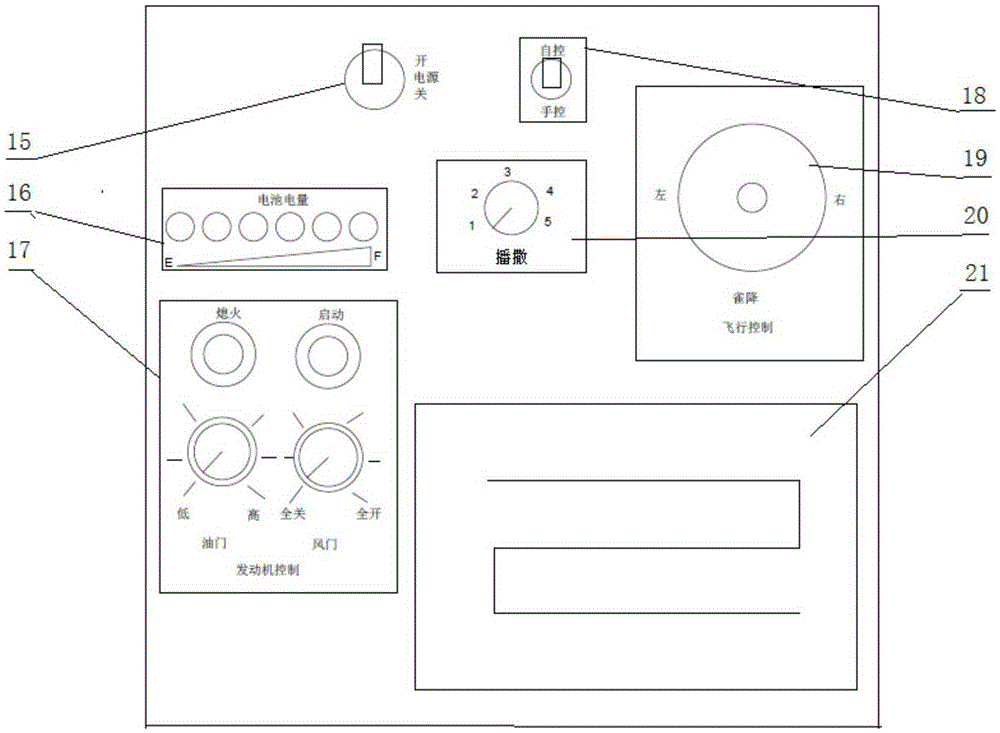

[0038] The intelligent sowing flight control system includes a steering gear 12 and an airborne flight control system 13 communicating with the ground station system. Steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com