Preparation method of high-purity graphite

A high-purity graphite and graphite technology, applied in the field of graphite chemical industry, can solve the problems of difficulty in further improving the purity of graphite, difficult to discharge completely in time, and increase in the concentration of impurity volatiles, so as to be conducive to large-scale industrial production, strong practical promotion value, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

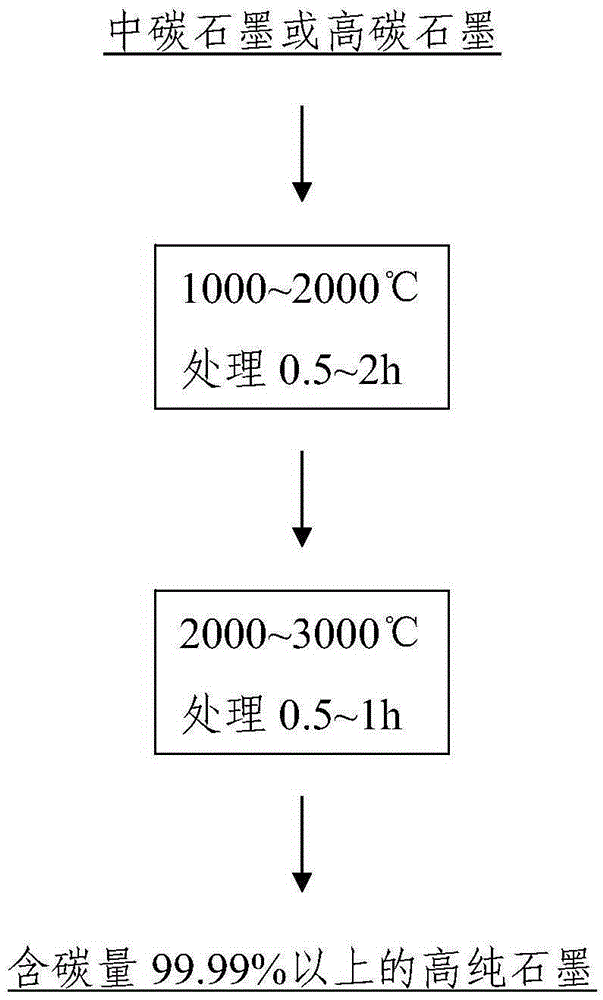

[0030] Follow the steps below to prepare high-purity graphite:

[0031] (1) Take graphite, grind it to a particle size of 200-300 μm, pass it into the first section of graphite purification device, and process it for 0.5h to obtain a solid product;

[0032] The treatment conditions of the first section are: temperature 2000°C, flow rate 8m 3 / h Continuously feed chlorine gas with a purity of more than 99%;

[0033] (2) The solid product obtained in step (1) is passed into the second section graphite purification device, and processed for 0.5h to obtain final product;

[0034] The treatment conditions of the second stage are: temperature 3000°C, flow rate 1m 3 / h Continuously feed chlorine gas with a purity of more than 99%.

[0035] After testing, the carbon content of the graphite after the step (1) is 99%, and the carbon content of the graphite after the step (2) is 99.99999%.

Embodiment 2

[0037] Follow the steps below to prepare high-purity graphite:

[0038] (1) Take graphite, grind it to a particle size of 200-300 μm, pass it into the first section of graphite purification device, and process it for 1 hour to obtain a solid product;

[0039] The treatment conditions of the first section are: temperature 1600°C, flow rate 8m 3 / h Continuously feed chlorine gas with a purity of more than 99%;

[0040] (2) The solid product obtained in step (1) is passed into the second section graphite purification device, and processed for 0.5h to obtain final product;

[0041] The treatment conditions of the second stage are: temperature 2600°C, flow rate 1m 3 / h Continuously feed chlorine gas with a purity of more than 99%.

[0042] After testing, the carbon content of the graphite after the step (1) is 99%, and the carbon content of the graphite after the step (2) is 99.9999%.

Embodiment 3

[0044] Follow the steps below to prepare high-purity graphite:

[0045] (1) Take graphite, grind it to a particle size of 200-300 μm, pass it into the first section of graphite purification device, and process it for 2 hours to obtain a solid product;

[0046] The treatment conditions of the first stage are: temperature 1000°C;

[0047](2) Pass the solid product of step (1) gained into the second section of graphite purification device, and process for 1h to obtain final product;

[0048] The processing conditions of the second stage are: temperature 2000°C, flow rate 2m 3 / h Continuously feed chlorine gas with a purity of more than 99%.

[0049] After testing, the carbon content of the graphite after the step (1) is 98%, and the carbon content of the graphite after the step (2) is 99.999%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com