Cooling device for glass sheet production line

A cooling device and production line technology, applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve problems such as uneven air supply, difficult to cool glass plates, and complicated air outlet layout, and achieve high equipment utilization and heat conduction The effect of high rate and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

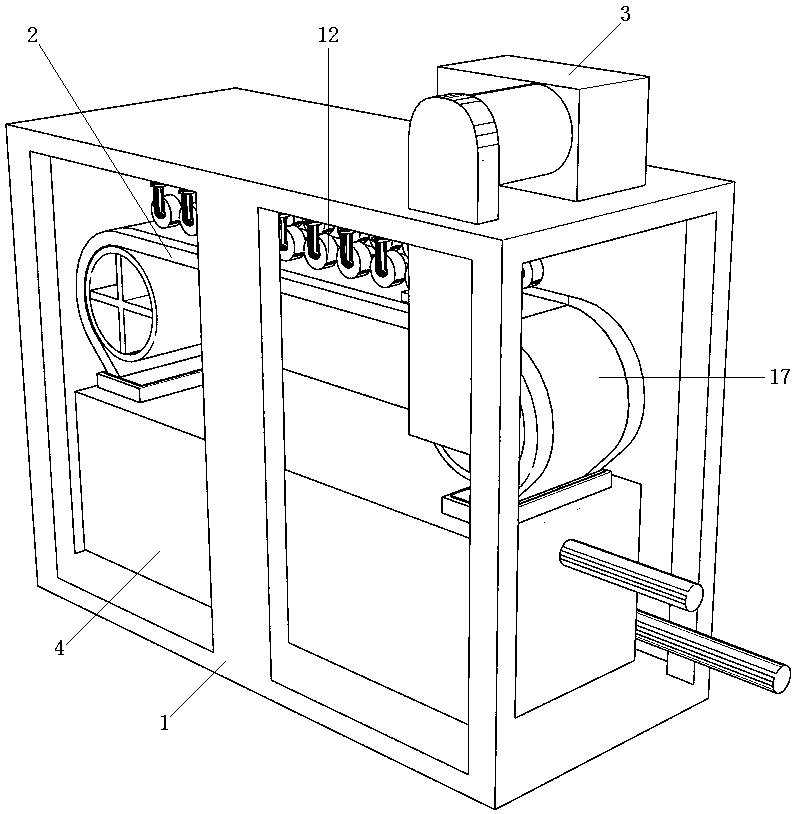

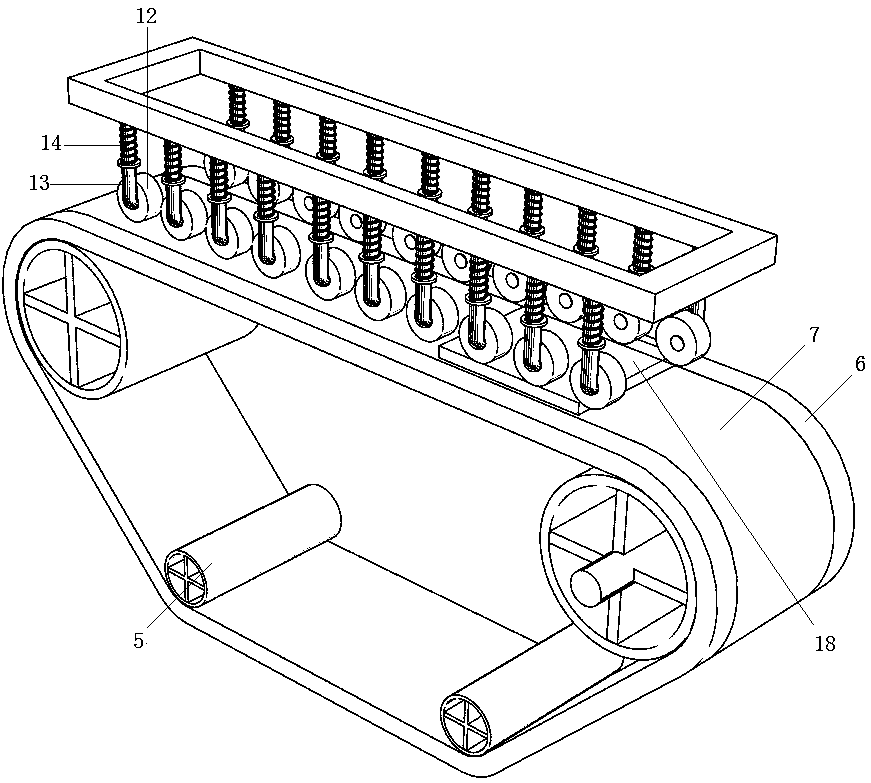

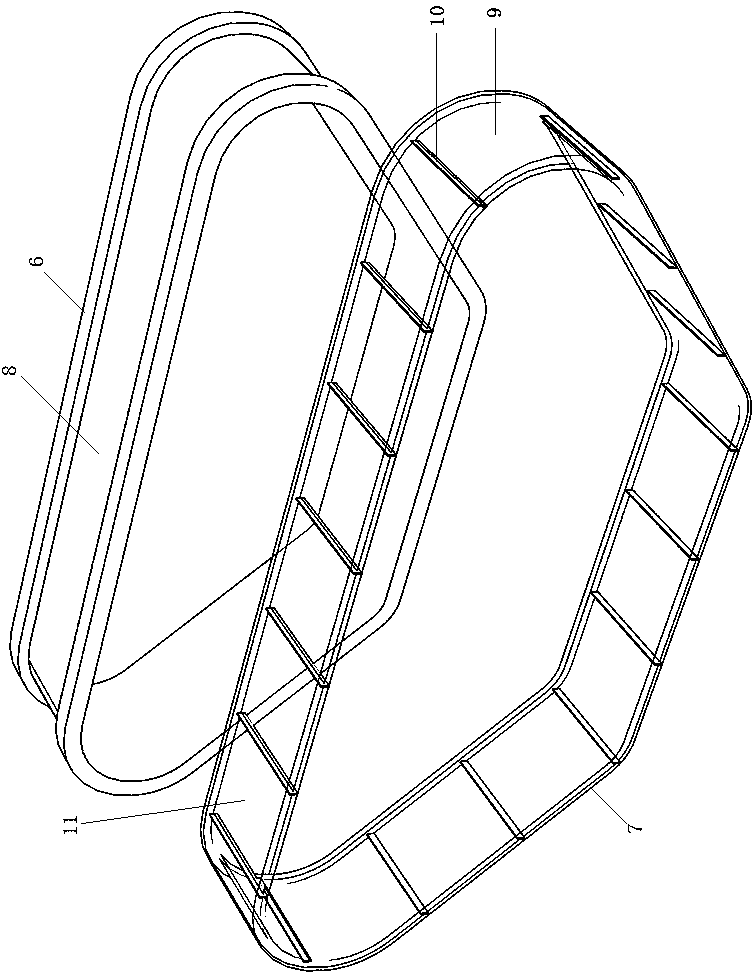

[0017] Figure 1-4 As shown, the glass sheet production line cooling device is characterized in that it includes a frame 1, a belt conveyor 2 installed at the bottom of the frame 1, a driving motor 3 of the belt conveyor 2 installed at the top of the frame 1; the belt conveyor 2 A cooling water heat exchanger 4 is installed directly below the cooling water heat exchanger 4; a guide wheel 5 is respectively installed on the left and right sides of the cooling water heat exchanger 4; the lower belt 17 of the belt conveyor 2 passes through the cooling water heat exchanger 4 and passes The belt 17 is bypassed on the wheel 5; the belt 17 is composed of a belt base 6 and a soft heat-conducting silicone belt 7; the middle part of the belt base 6 is provided with a groove 8; the soft heat-conducting silicone belt 7 fits in the groove 8; the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com