Cooling system for tempered glass and cooling method thereof

A cooling system and tempered glass technology, which is applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased energy consumption and equipment cost in processing, so as to improve quality, reduce noise and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] refer to Figure 1 to Figure 7 The embodiments of the present invention will be further described.

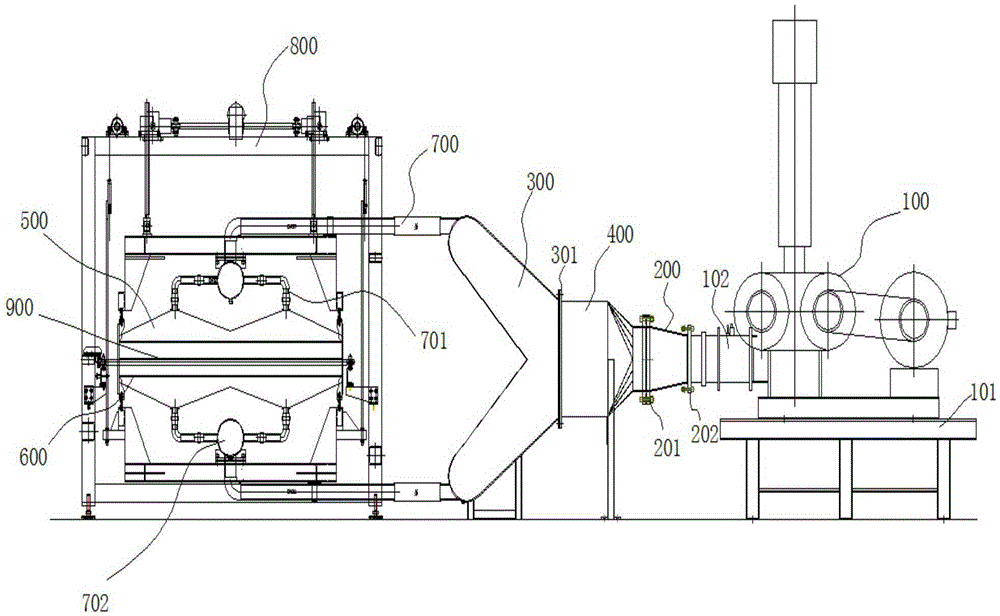

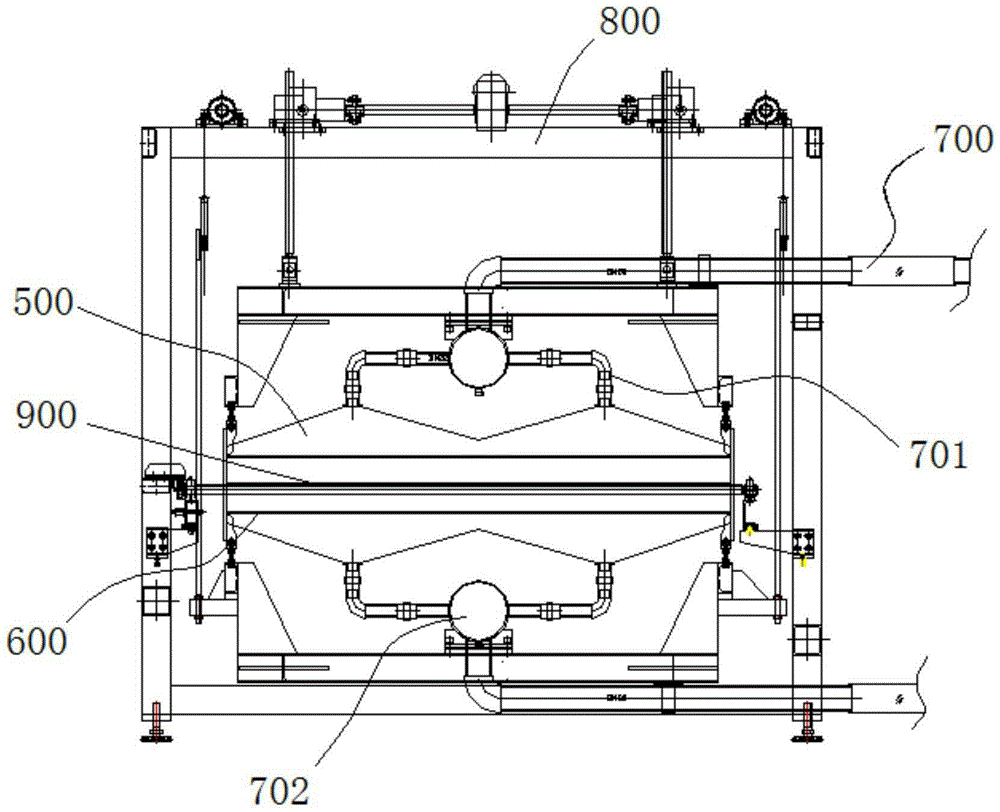

[0026] refer to figure 1 : A cooling system for tempered glass, which is arranged in an assembly line, and sequentially includes a Roots blower 100 for generating cooling air flow: an air outlet pipe 102 is arranged on the Roots blower 100, in order to improve its air delivery capacity, A base 101 is provided on the Roots blower 100, and the air outlet pipe 102 and the conveying roller table 900 are kept as horizontal as possible by adjusting the base 101;

[0027] Muffler 200 for reducing noise on the air outlet pipe 102 of the Roots blower 100: one end of the muffler 200 is connected to the air outlet pipe 102 through the first flange 202, and the other end is fixedly connected to the air cooling device 400 through the second flange 201 ;

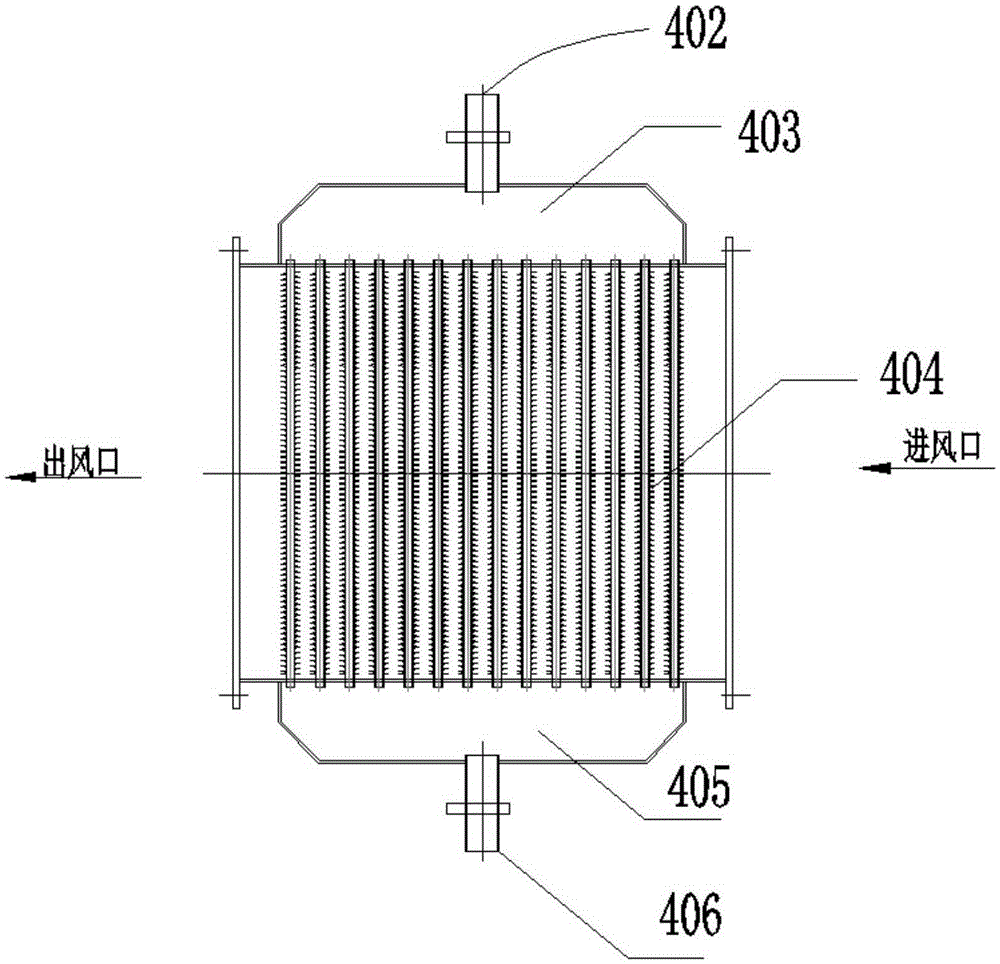

[0028] The wind distribution air box 300 that divides the cooling air flow divides the cooling air flow into upper and lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com