High-glossiness anti-flaming polypropylene material easy to clean and preparation method thereof

A technology of flame-retardant polypropylene and high-gloss flame-retardant masterbatch, which is applied in the field of thermoplastic polyolefins, can solve the problems of being difficult to clean, affecting the appearance characteristics of external parts of household appliances, easily contaminated with grease, etc. Stable and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

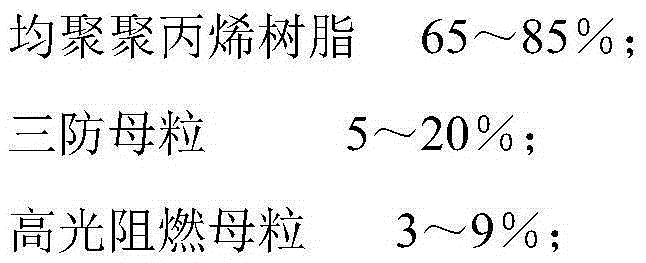

[0039] Proportioning is carried out according to the following mass percentage composition: homopolypropylene resin (brand name: PPH-MM20-S, melt index (230°C, 2.16KG): 20g / 10min, China Petrochemical Corporation Maoming Branch) 65%, Three-proof masterbatch (model: TG-PPL20, Daikin Fluorine Chemicals (China) Co., Ltd.) 18%, high-gloss flame-retardant masterbatch (self-made, the preparation method is as above, the grade of high-gloss flame retardant used is: M-208NPB, Shanghai Meilaipo Chemical Material Technology Co., Ltd.) 7%, dolomite masterbatch (self-made, the preparation method is as above, the average particle size of dolomite used is 6.2 μm, Lingshou County Xinjing Mineral Products Processing Factory) 10%.

[0040] Accurately weigh the above materials and stir evenly, then add them into the main feeding hopper of a parallel twin-screw extruder with a length-to-diameter ratio of 44:1, and set the temperature of each section of the extruder from the hopper to the die head t...

Embodiment 2

[0043] Proportioning is carried out according to the following mass percentage composition: homopolypropylene resin (brand name: PPH-MM20-S, melt index (230°C, 2.16KG): 20g / 10min, China Petrochemical Corporation Maoming Branch) 69%, Three-proof masterbatch (model: TG-PPL20, Daikin Fluorine Chemicals (China) Co., Ltd.) 20%, high-gloss flame-retardant masterbatch (self-made, the preparation method is as above, the grade of high-gloss flame retardant used is: M-208NPB, Shanghai Meilaipo Chemical Material Technology Co., Ltd.) 3%, dolomite masterbatch (self-made, the preparation method is as above, the average particle size of dolomite used is 6.2 μm, Lingshou County Xinjing Mineral Products Processing Factory) 8%.

[0044] Accurately weigh the above materials and stir evenly, then add them into the main feeding hopper of a parallel twin-screw extruder with a length-to-diameter ratio of 44:1, and set the temperature of each section of the extruder from the hopper to the die head to...

Embodiment 3

[0047] Proportion according to the following mass percentage composition: homopolypropylene resin (brand: PPH8020, melt index (230°C, 2.16KG): 20g / 10min, Langang Petrochemical Co., Ltd.) 81%, three-proof masterbatch (model : TG-PPL20, Dajin Fluorine Chemicals (China) Co., Ltd.) 5%, high-gloss flame retardant masterbatch (self-made, the preparation method is as above, the grade of high-gloss flame retardant used is: FR6000, Dongguan Chuangzhiyuan Chemical Co., Ltd.) 9%, dolomite masterbatch (self-made, the preparation method is as above, and the average particle diameter of used dolomite is 7.5 μm and is produced by Guilin Jinsanhua Powder Chemical Co., Ltd.) 5%.

[0048] Accurately weigh the above materials and stir evenly, then add them into the main feeding hopper of a parallel twin-screw extruder with a length-to-diameter ratio of 44:1, and set the temperature of each section of the extruder from the hopper to the die head to be : 180°C, 180°C, 210°C, 210°C, 190°C, 190°C, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com