A kind of oriented flexible magnetoelectric composite material and its preparation method

A magnetoelectric composite material and flexible technology, which is applied in the field of oriented flexible magnetoelectric composite material and its preparation, can solve the problems of limited improvement of magnetoelectric coupling performance and relatively few studies on the influence relationship of magnetoelectric coupling performance. Excellent mechanical properties and magnetoelectric coupling performance, improved interfacial compatibility, and enhanced magnetostrictive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

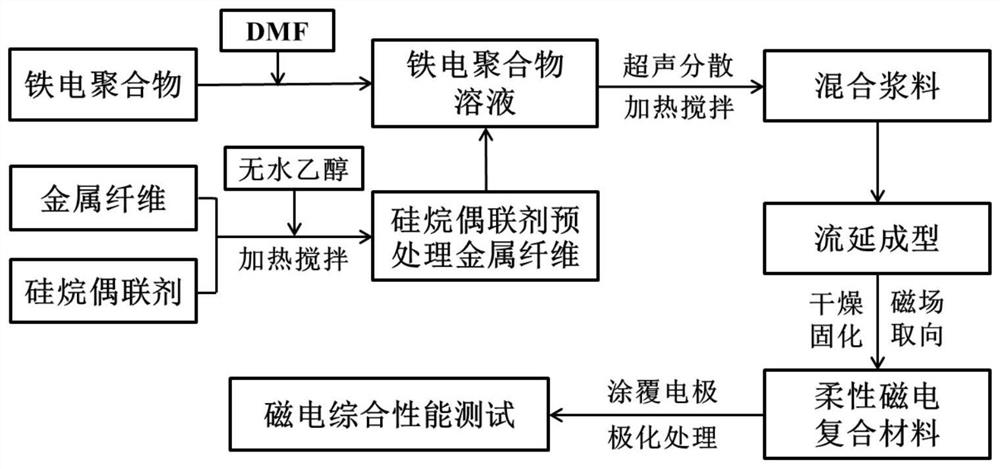

[0038] In this embodiment, the oriented flexible magnetoelectric composite material, the ferroelectric polymer is vinylidene fluoride-trifluoroethylene copolymer, wherein the molar ratio of vinylidene fluoride:trifluoroethylene is 3:1; the metal fiber is iron fiber, The massfraction of iron fiber in the composite material is 15%; Concrete preparation method comprises as follows:

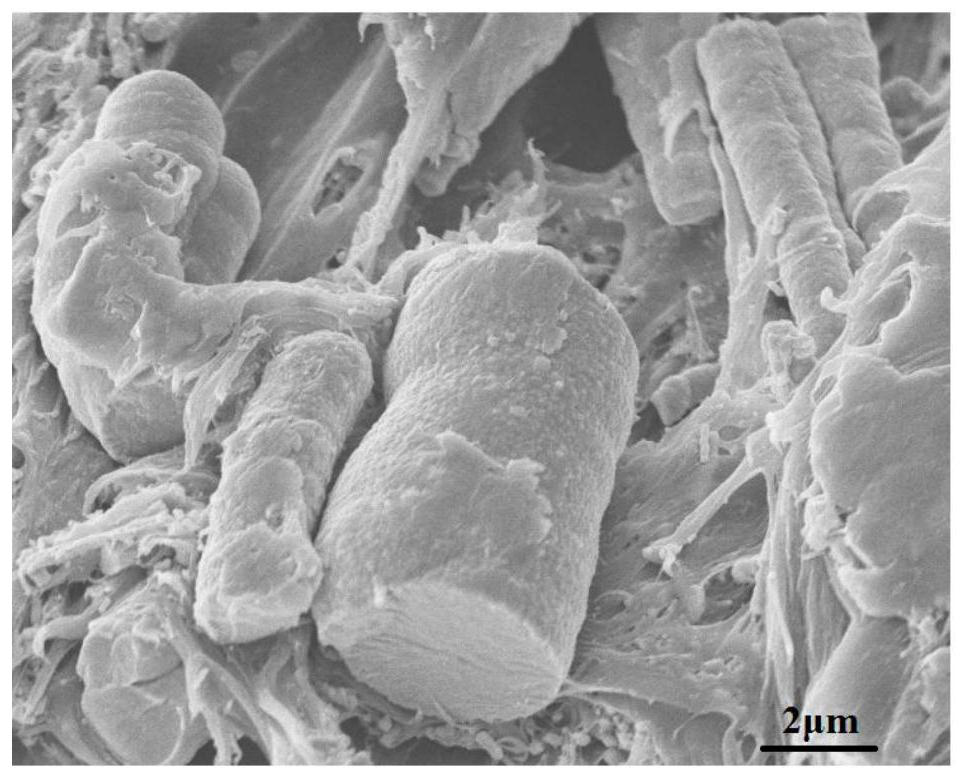

[0039] (1) Surface treatment of iron fibers: Weigh 4g of iron fibers, place them in a beaker filled with 30mL of absolute ethanol, drop 0.2g of silane coupling agent KH550 (purity 98%), and ultrasonically disperse for 30min; The mixture beaker was placed in a water bath at a constant temperature of 60°C, and mechanically stirred with a precision booster electric stirrer for 40 minutes; then dried in a vacuum oven to obtain iron fibers surface-treated with a silane coupling agent;

[0040] (2) Preparation of ferroelectric polymer solution: Weigh 10g of ferroelectric polymer powder, then add it into 5m...

Embodiment 2

[0051] In this embodiment, the oriented flexible magnetoelectric composite material, the ferroelectric polymer is vinylidene fluoride-trifluoroethylene copolymer, wherein the molar ratio of vinylidene fluoride:trifluoroethylene is 4:1; the metal fiber is iron fiber, The massfraction of iron fiber in the composite material is 20%, and its preparation method comprises the steps:

[0052] (1) Surface treatment of iron fibers: Weigh 4g of iron fibers, put them in a beaker filled with 50mL of absolute ethanol, drop in 0.25g of silane coupling agent KH550 (purity 98%), and ultrasonically disperse for 30min; The beaker was placed in a water bath, kept at a constant temperature of 70°C, and mechanically stirred with a precision booster electric stirrer for 30 minutes; then dried in a vacuum oven to obtain iron fibers surface-treated with a silane coupling agent;

[0053] (2) Preparation of ferroelectric polymer solution: Weigh 10g of ferroelectric polymer powder, then add it into 5mL ...

Embodiment 3

[0059] In this embodiment, the oriented flexible magnetoelectric composite material, the ferroelectric polymer is vinylidene fluoride-trifluoroethylene copolymer, wherein the molar ratio of vinylidene fluoride:trifluoroethylene is 4:1; the metal fiber is iron fiber, The mass fraction of iron fibers in the composite is 15%. Its preparation method comprises the following steps:

[0060] (1) Surface treatment of iron fibers: Weigh 4g of iron fibers, place them in a beaker filled with 50mL of absolute ethanol, drop in 0.25g of silane coupling agent KH550 (purity 98%), and ultrasonically disperse for 30min; The mixture beaker was placed in a water bath, kept at a constant temperature of 70 ° C, and mechanically stirred with a precision booster electric stirrer for 30 minutes; then dried in a vacuum oven to obtain iron fibers surface-treated with a silane coupling agent;

[0061] (2) Preparation of ferroelectric polymer solution: Weigh 10g of ferroelectric polymer powder, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com