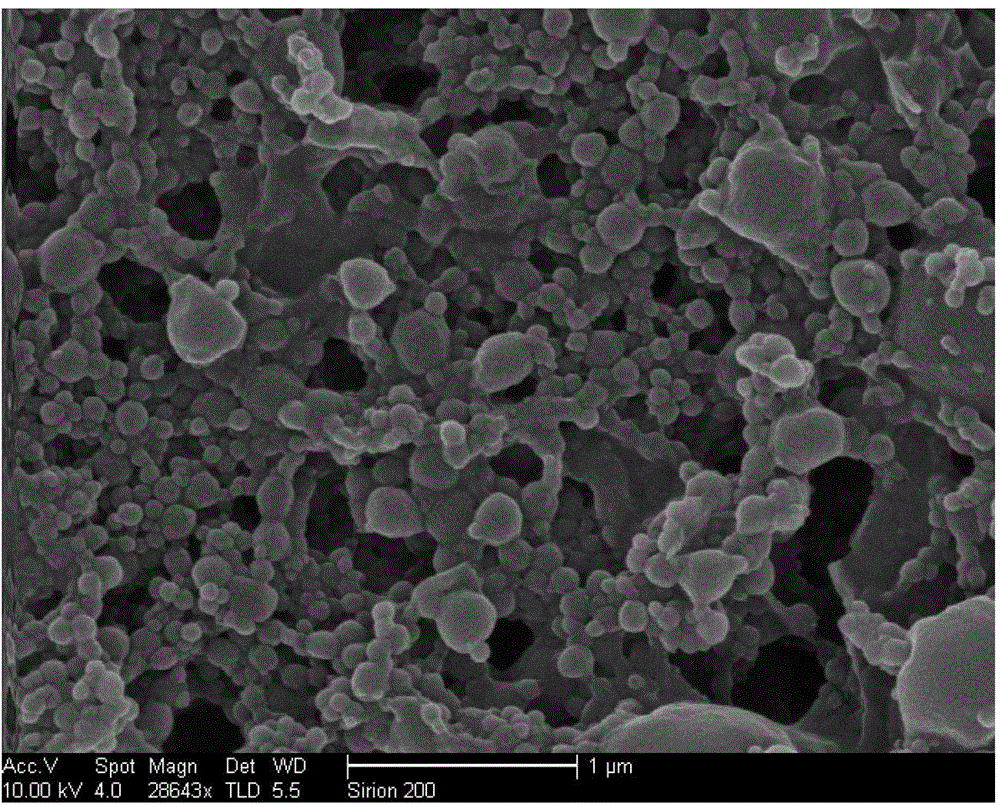

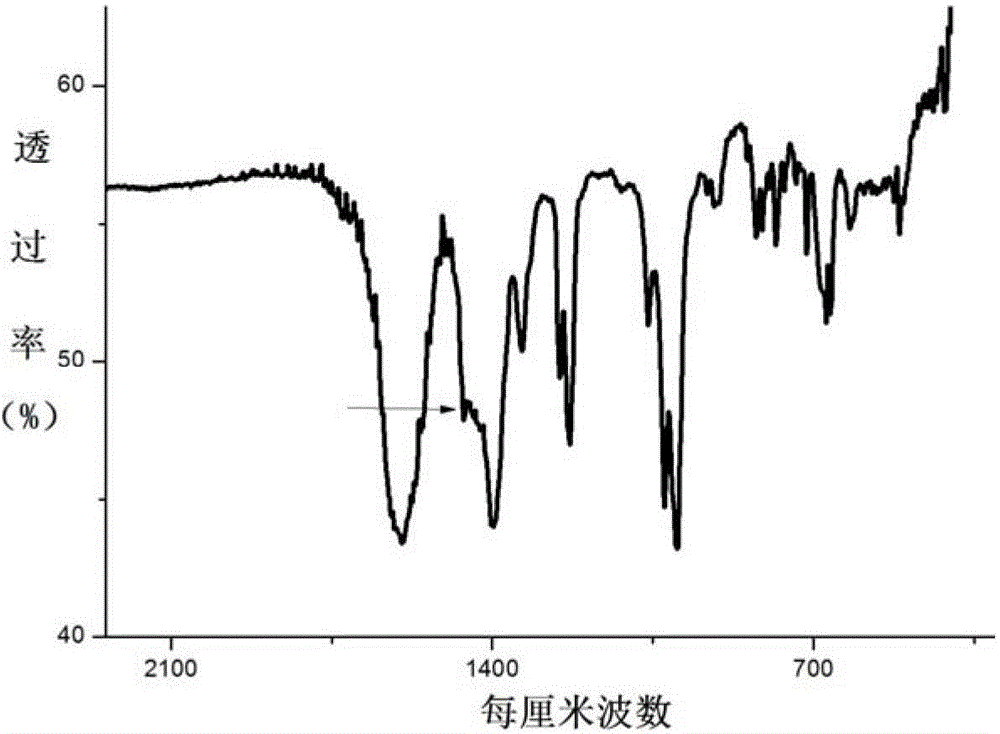

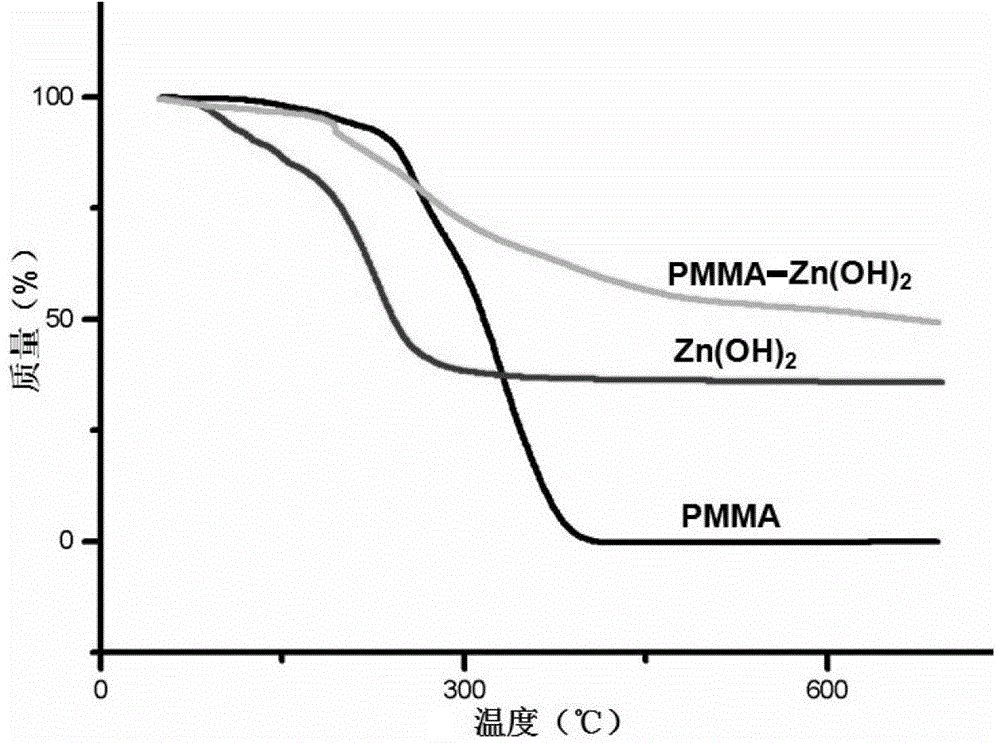

Polymethyl methacrylate-zinc hydroxide nanocomposite material and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate is applied in the field of polymethyl methacrylate-zinc hydroxide nanocomposite material and preparation thereof, and can solve the problem of large-scale popularization and application of unfavorable products, difficult thermal stability , poor dispersion and other problems, to achieve excellent thermal stability performance, improve thermal stability, thermal performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The concrete steps of preparation are:

[0039] Step 1, first mix the soluble ammonium salt, soluble zinc salt and water according to the ratio of ammonium ion: zinc ion: water molar ratio of 1:1:20, and stir evenly at 60°C; wherein, the soluble ammonium salt is Hexamethylenetetramine, the soluble zinc salt is zinc nitrate, and the water is deionized water to obtain a mixed solution. Add methyl methacrylate to the mixed solution and stir to obtain a composite solution; wherein, the molar ratio of methyl methacrylate to zinc ions in the composite solution is 10:1.

[0040]Step 2, first add an emulsifier to the composite liquid, and vigorously stir and emulsify for 1 hour to obtain an emulsion; wherein, the mass ratio of the emulsifier in the emulsion to methyl methacrylate is 1.5:10, and the emulsifier is dodecane sodium sulfate. Add an initiator to the emulsion, and react for 2 hours to obtain a composite emulsion; wherein, the mass ratio of the initiator in the compo...

Embodiment 2

[0043] The concrete steps of preparation are:

[0044] Step 1, first mix soluble ammonium salt, soluble zinc salt and water according to the molar ratio of ammonium ion: zinc ion: water is 2:1:40, and stir evenly at 63°C; wherein, the soluble ammonium salt is Hexamethylenetetramine, the soluble zinc salt is zinc nitrate, and the water is deionized water to obtain a mixed solution. Add methyl methacrylate to the mixed liquid and stir to obtain a composite liquid; wherein, the molar ratio of methyl methacrylate to zinc ions in the composite liquid is 33:1.

[0045] Step 2, first add an emulsifier to the composite liquid, and vigorously stir and emulsify for 1.3 hours to obtain an emulsion; wherein, the mass ratio of the emulsifier in the emulsion to methyl methacrylate is 1.25:10, and the emulsifier is twelve Sodium Alkyl Sulfate. Then add an initiator to the emulsion, and react for 3 hours to obtain a composite emulsion; wherein, the mass ratio of the initiator in the composi...

Embodiment 3

[0048] The concrete steps of preparation are:

[0049] Step 1, first mix soluble ammonium salt, soluble zinc salt and water according to the molar ratio of ammonium ion: zinc ion: water is 3:1:60, and stir evenly at 65°C; wherein, the soluble ammonium salt is Hexamethylenetetramine, the soluble zinc salt is zinc nitrate, and the water is deionized water to obtain a mixed solution. Add methyl methacrylate to the mixed liquid and stir to obtain a composite liquid; wherein, the molar ratio of methyl methacrylate and zinc ions in the composite liquid is 55:1.

[0050] Step 2, first add an emulsifier to the compound liquid, and vigorously stir and emulsify for 1.5h to obtain an emulsion; wherein, the mass ratio of the emulsifier in the emulsion to methyl methacrylate is 1:10, and the emulsifier is twelve Sodium Alkyl Sulfate. Add an initiator to the emulsion, and react for 4 hours to obtain a composite emulsion; wherein, the mass ratio of the initiator in the composite emulsion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com