Asphalt Additives for Warm Mix and Their Applications

An asphalt additive and warm mixing technology, which is applied in the field of petroleum asphalt warm mixing, can solve the problems of difficult modification of rubber powder, environmental pollution, and high energy consumption, and achieve the goal of improving thermal aging, overcoming environmental pollution, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

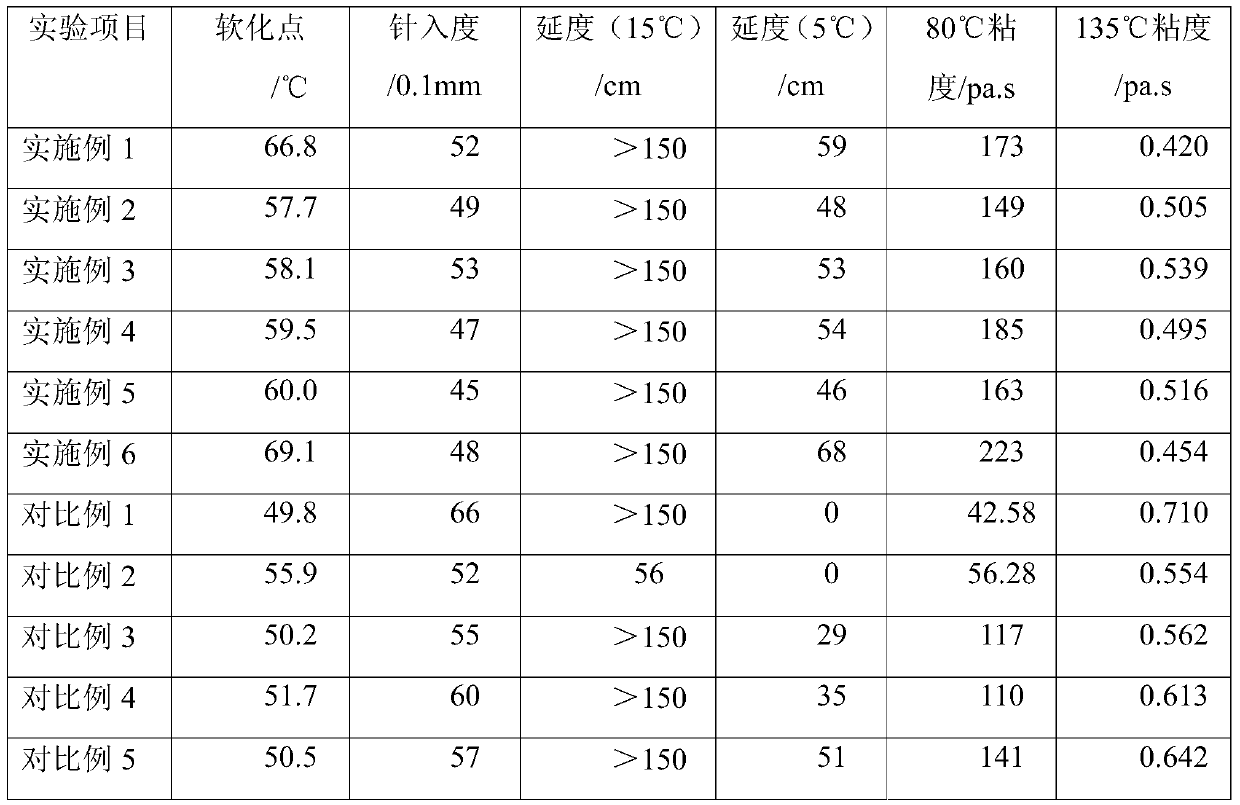

Examples

Embodiment 1

[0027] Heat 100 parts of base asphalt to 130°C, add 2 parts of paraffin wax, 0.5 parts of stearic acid amide and 5 parts of styrene-butadiene rubber powder and stir at a constant temperature of 120°C for 20 minutes, then add 0.05 parts of plasticized sulfur and stir at 150°C for 1 hour. (wherein embodiment 1 used paraffin melting point 88 ℃, rubber powder particle size 10 orders, stearamide melting point 110 ℃)

Embodiment 2

[0029] Heat 100 parts of base asphalt to 132°C, add 2.5 parts of paraffin wax, 1.0 part of stearic acid amide and 6 parts of styrene-butadiene rubber powder and stir at a constant temperature of 110°C for 15 minutes, then add 0.15 parts of plasticized sulfur and stir at 140°C for 1.2 hours. (wherein embodiment 2 used paraffin melting point 85 ℃, rubber powder particle size 40 orders, stearamide melting point 105 ℃)

Embodiment 3

[0031] Heat 100 parts of base asphalt to 133°C, add 1 part of paraffin wax, 1.5 parts of stearic acid amide and 15 parts of styrene-butadiene rubber powder and stir at a constant temperature of 130°C for 20 minutes, then add 0.35 parts of plasticized sulfur and stir at 145°C for 0.8 hours. (wherein embodiment 3 used paraffin melting point 85 ℃, rubber powder particle size 50 orders, stearamide melting point 110 ℃)

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com