Anti-cracking multi-gradual-division type resin injection blow molding process

An injection blow molding and anti-cracking technology, which is applied in the field of resin molding technology to achieve the effects of ensuring quality, reducing self-weight sagging, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

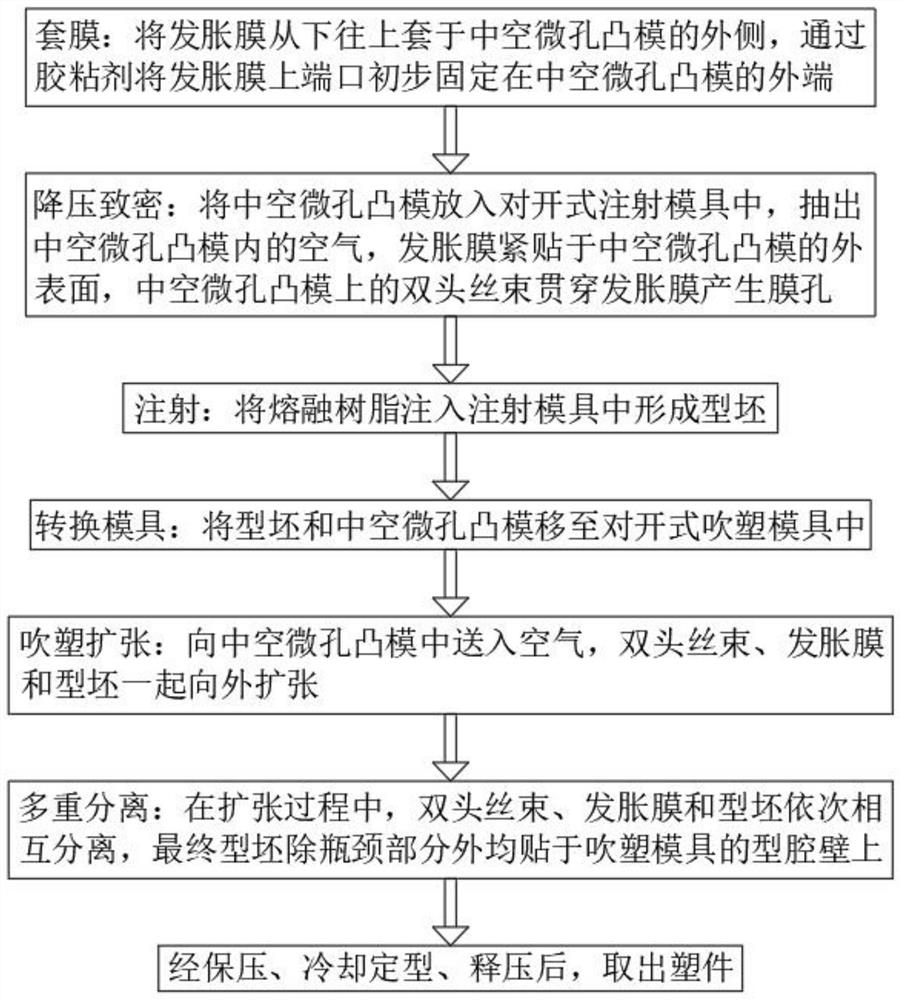

[0053] see figure 1 , figure 2 and image 3 , an anti-cracking multi-gradient resin injection blow molding process, comprising the following steps:

[0054] S1. Membrane: Put the expansion film 2 on the outside of the hollow microporous punch from bottom to top, and initially fix the upper port of the expansion film 2 on the outer end of the hollow microporous punch with an adhesive;

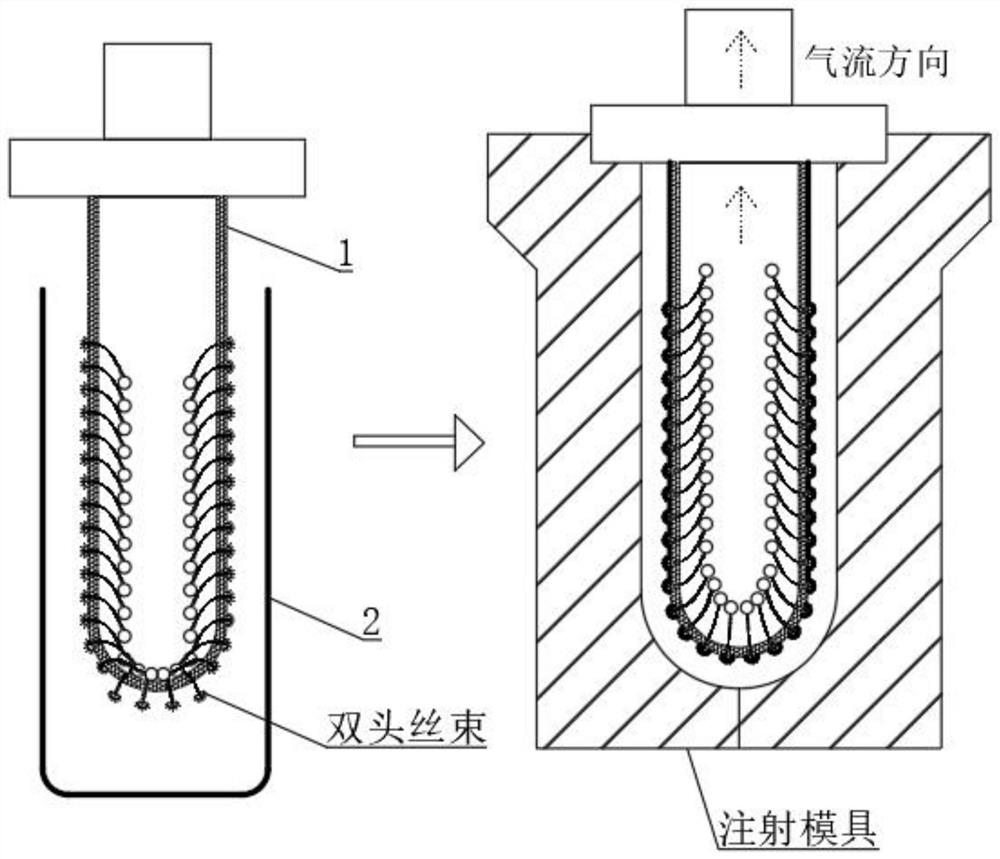

[0055] S2. Depressurization and compaction: put the hollow microporous punch into the split injection mold, then the mold is closed and fixed, and the air in the hollow microporous punch is drawn out, so that the swelling film 2 is closely attached to the outer surface of the hollow microporous punch, The double-ended filaments on the hollow microporous punch run through the swelling membrane 2 to produce membrane holes;

[0056] S3. Injection: inject molten resin into the injection mold to form a parison;

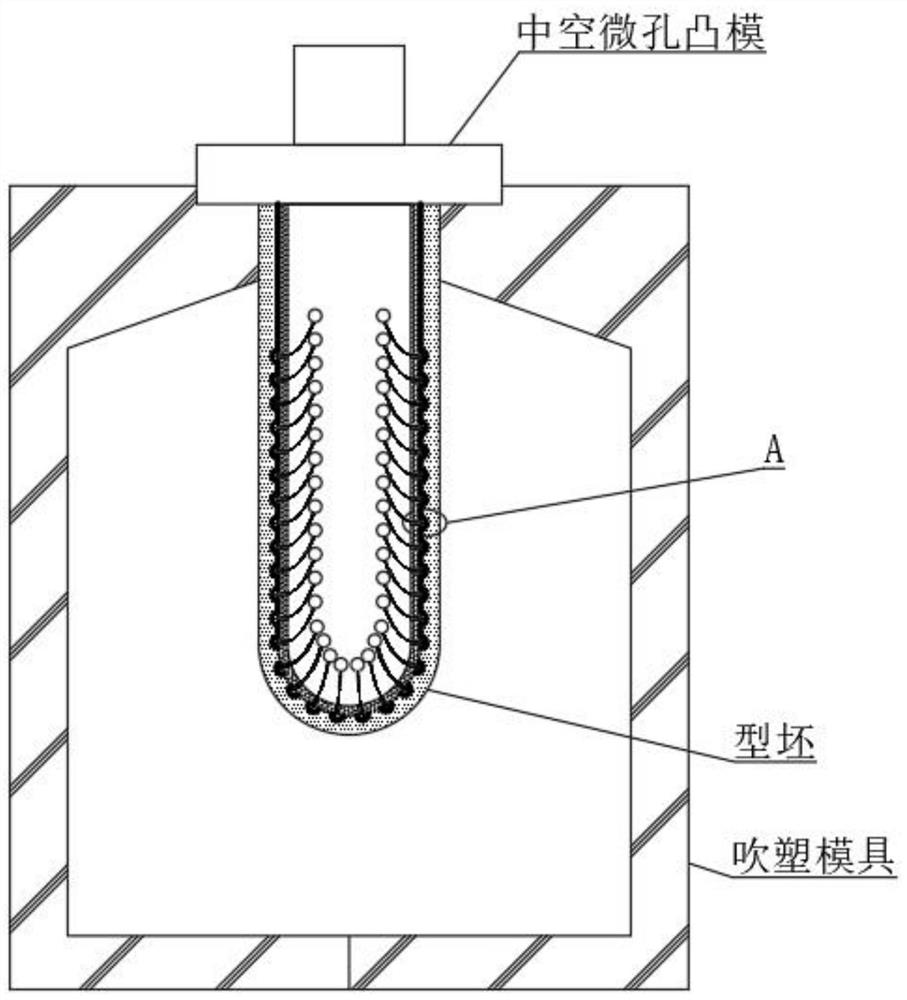

[0057] S4, conversion mold: the parison and the hollow microporous punch are taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com