Combined measurement method of electroacoustical sensor for flow parameters oil-gas-water three-phase flow

A technology of acoustic and electric sensors and measurement methods, applied in the directions of measurement, earthwork drilling and production, boreholes/well components, etc., can solve the problems of slow measurement response speed, total flow measurement error, and low measurement accuracy, and improve local flow velocity and Effect of non-uniform distribution of local concentration, high reliability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings and embodiments. The combined measurement method of the acousto-electric sensor for oil, gas and water three-phase flow flow parameters mainly includes the following steps:

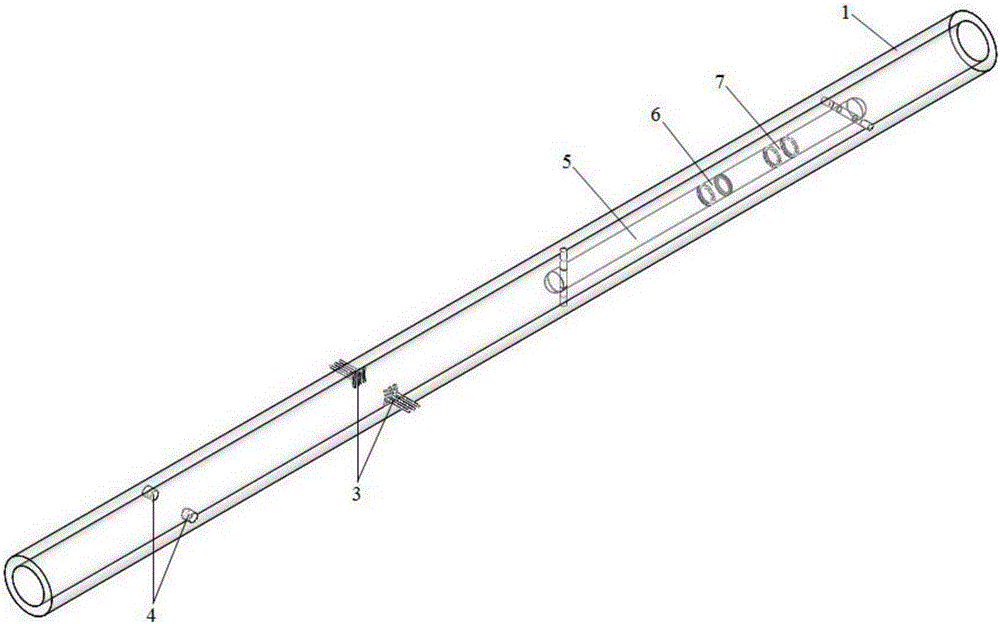

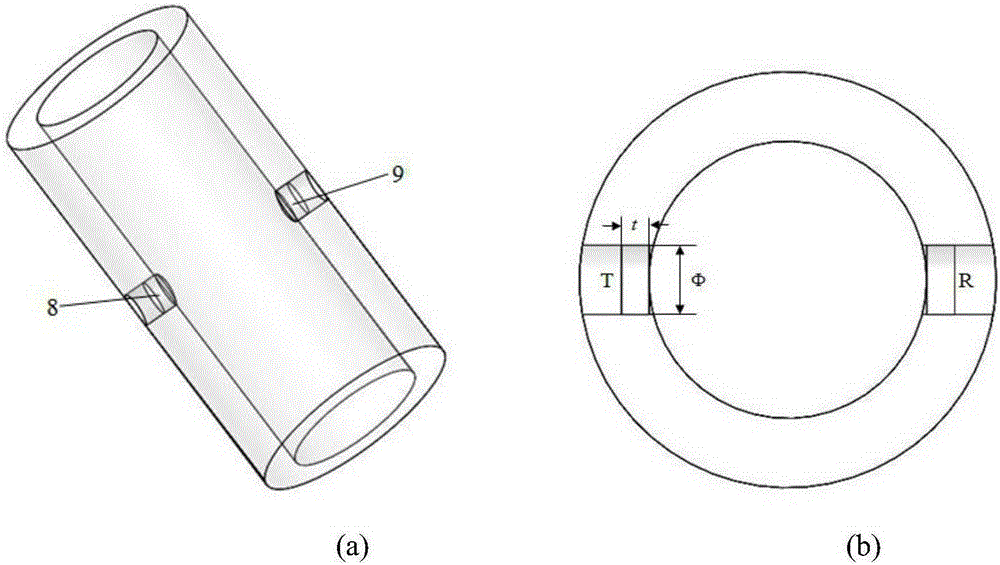

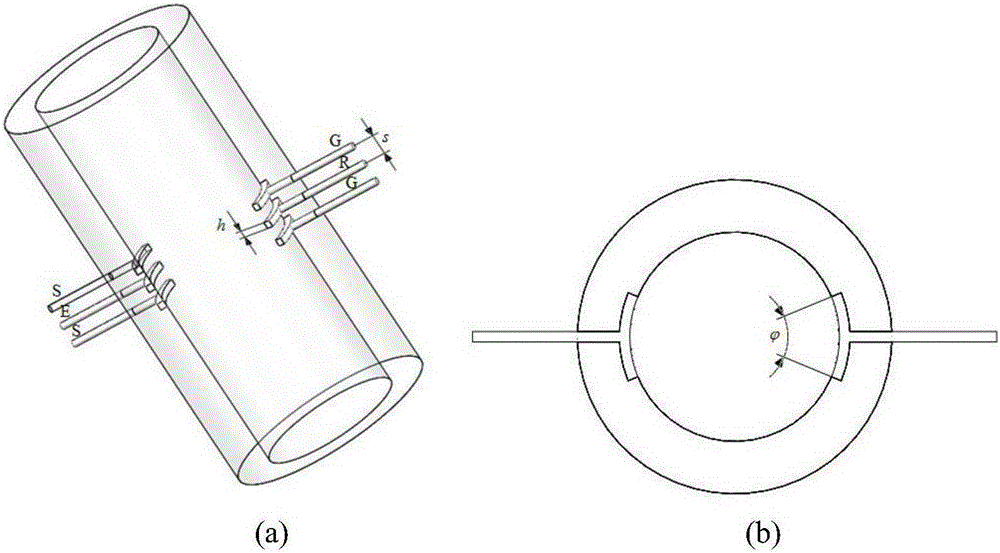

[0026] (1) Design a combined measurement system with acoustic and electrical sensors for oil, gas and water three-phase flow, which is used to measure the relative velocity and phase holdup (gas holdup, water holdup, and oil holdup) of the oil, gas and water three-phase flow with water as the continuous phase. The combined structure of the acoustic and electrical sensors is as follows figure 1 Shown. Considering that the inner diameter of the measurement channel of the downhole production profile production logging tool is mostly 20mm, the acoustic-electric sensor assembly of the present invention is sequentially installed in the vertical small pipeline (inner diameter 20mm) from bottom to top: pulse transmission ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com