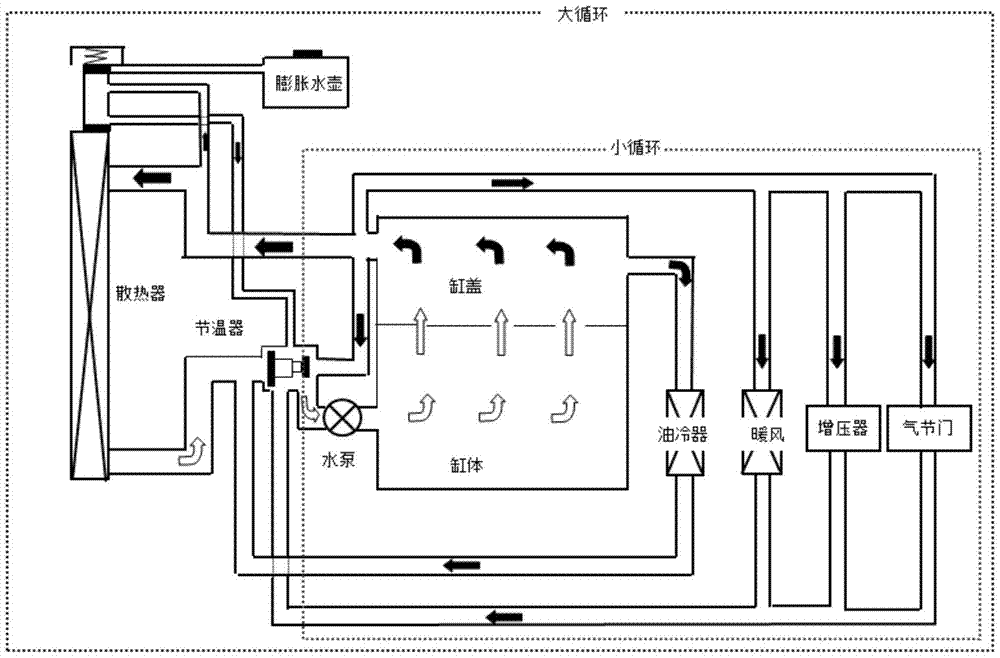

A dual cooling system for supercharged and miniaturized engines

A cooling system and engine technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of difficult layout, complex calculation of heat damage, slow response, etc., to improve cooling effect, ensure air intake efficiency, The effect of ensuring the intake air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

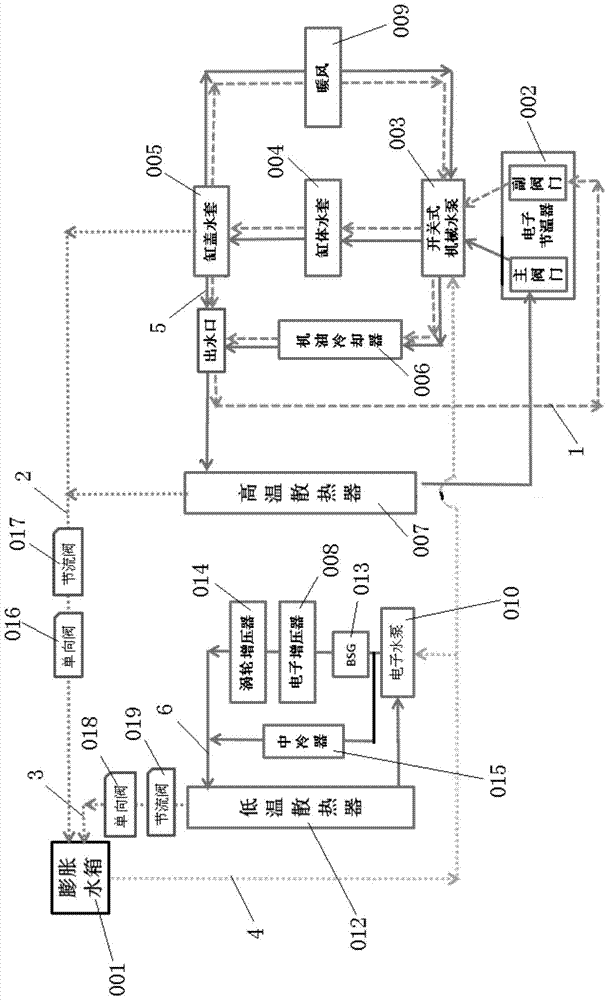

[0041] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0042] Definition of key components

[0043] BSG: (Belt Starter Generator) A belt starter generator system: it can realize the engine start / stop function, realize energy recovery, auxiliary torque increase and other functions.

[0044] Electronic supercharger: (Electric Super-Charger ESC) is an electronic matching product that can improve the ignition and combustion state of the automobile engine. Its main function is to improve the low-end torque and torque responsiveness of the engine. The speed of the motor is dragged to 70,000 rpm, and air is needed to cool the motor, which is integrated inside the air filter.

[0045] Electronic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com