Transparent cable difficult to discern and easy for indoor wiring

An indoor wiring and transparent technology, applied in the field of cables, can solve the problems of poor resistance to torsion and flexure, thick sheath, poor bending resistance, etc., to reduce resistance and difficulty, high user acceptance, The effect of quick and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

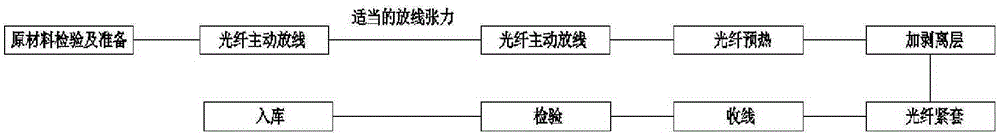

Method used

Image

Examples

Embodiment

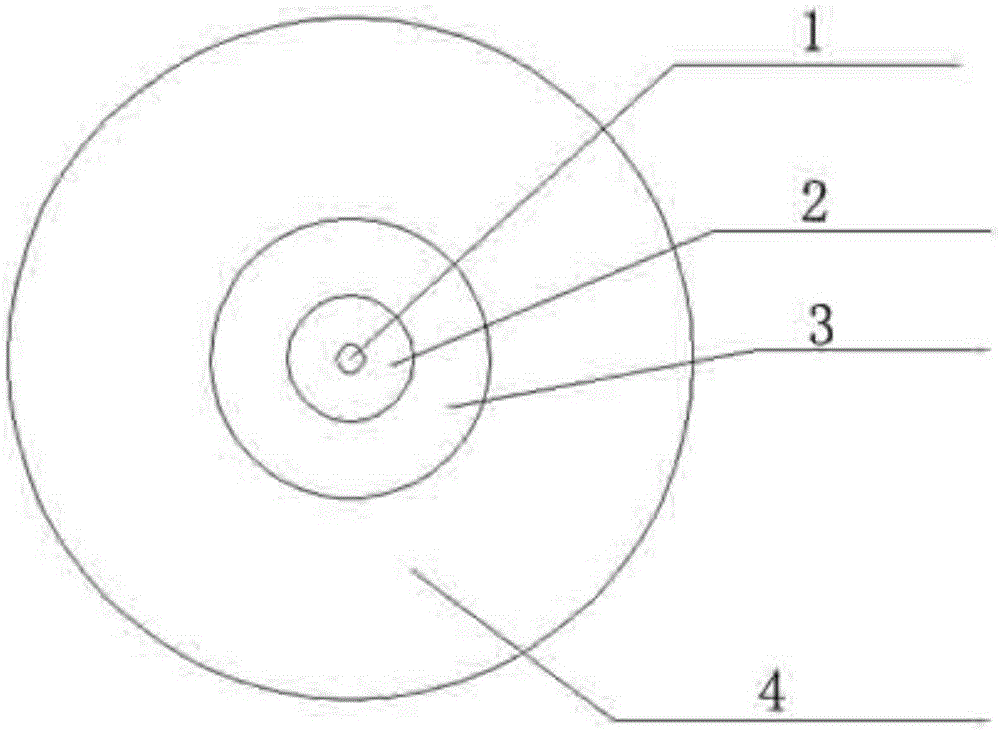

[0020] Such as figure 1 The cable of the present invention includes a cable core 1 located inside, and the outer ring of the cable core 1 is coated with a cladding 2, a coating 3 and a protective layer 4 in sequence. In this embodiment, the cladding is 125um thick, and the coating The thickness is 250um, and the protective layer is made of transparent thermoplastic elastomer, with a thickness of 900um.

[0021] (1) Basic structure of optical cable

[0022] The selection of optical cable materials and structures should be suitable for the intended use and installation conditions. The optical cable sheath should be made of transparent thermoplastic. The optical cable should have good transparency, and there is no obvious color difference between the optical fiber and the sheath.

[0023] (2) Typical size of optical cable

[0024] The typical structural size of the optical cable should meet 0.9mm (tolerance 0.05mm).

[0025] (3) Requirements for optical fibers in optical cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com