Laser pattern device and laser pattern optical mesh of invisible sensor layer of touch panel

A touch panel and sensing layer technology, applied in the field of laser patterning, can solve problems such as damage or pollution, substrate bending, etc., and achieve the effects of simplifying the process, transferring patterns accurately, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The laser patterning equipment and the laser patterning grid of the invisible sensing layer of the touch panel according to the preferred embodiment of the present invention will be described below with reference to the relevant drawings, wherein the same elements will be described with the same reference symbols .

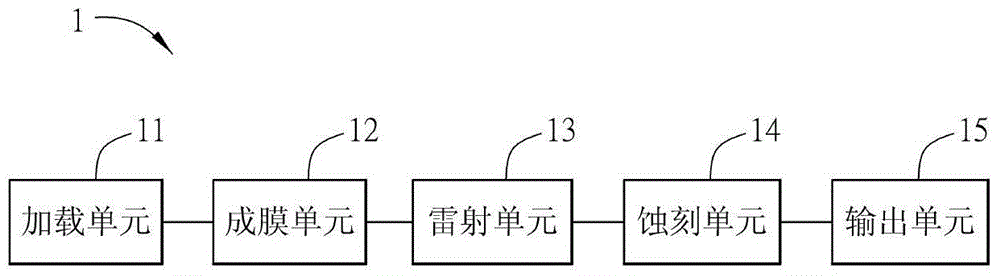

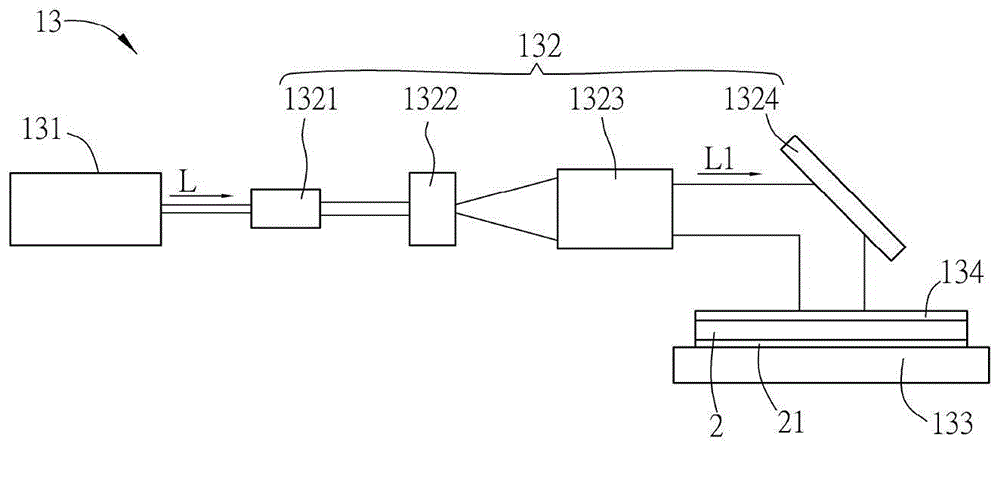

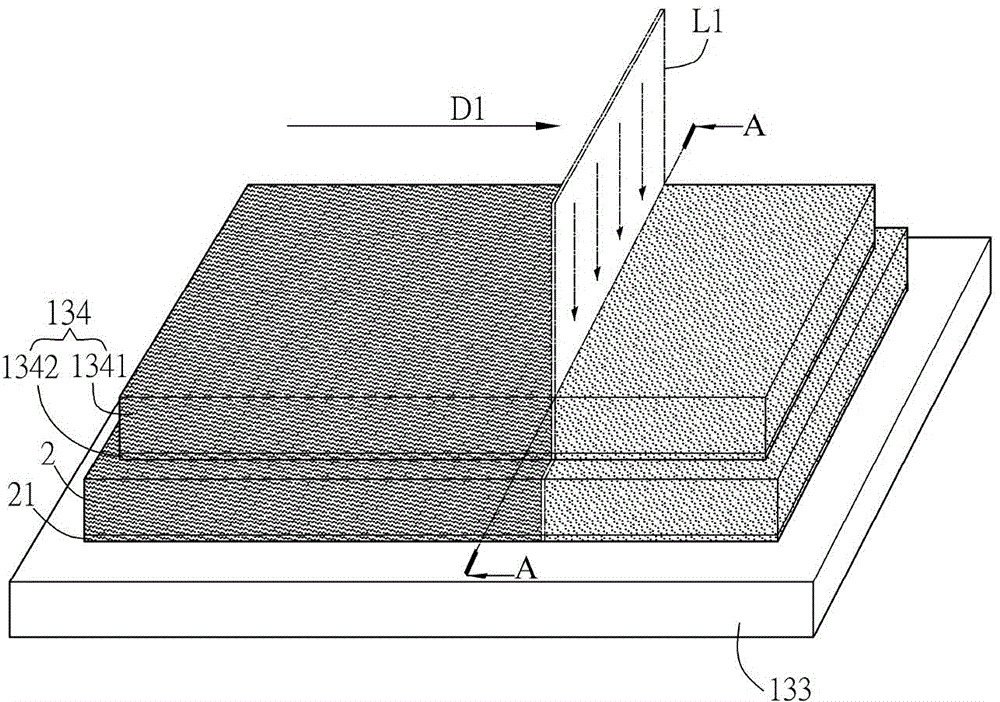

[0039] figure 1 It is a functional block diagram of the laser patterning device for the invisible sensing layer of the touch panel according to the preferred embodiment of the present invention. Please refer to figure 1 As shown, the laser patterning device 1 can be used to form pixel electrodes of a display panel, touch electrodes (touch sensing structure) of a touch panel, or other conductive structures such as wires or ground wires. In this embodiment, it is described by taking the formation of an invisible sensor layer of a touch panel as an example. Here, the laser patterning device 1 includes a loading unit 11 , a film forming unit 12 , a laser uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com