Zinc-manganese flow battery

A flow battery, zinc-manganese technology, applied in the direction of alkaline storage batteries, alkaline storage battery electrodes, etc., can solve problems such as cross-contamination costs, achieve long cycle life, simple structure and manufacturing process, and solve cross-contamination effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Electrolyte configuration:

[0023] Electrolyte: Electrolyte 40ml, which contains 1.0moldm -3 MnSO 4 , 1 mold m -3 ZnSO 4 , 0.2moldm -3 h 2 SO 4 .

[0024] Battery Assembly:

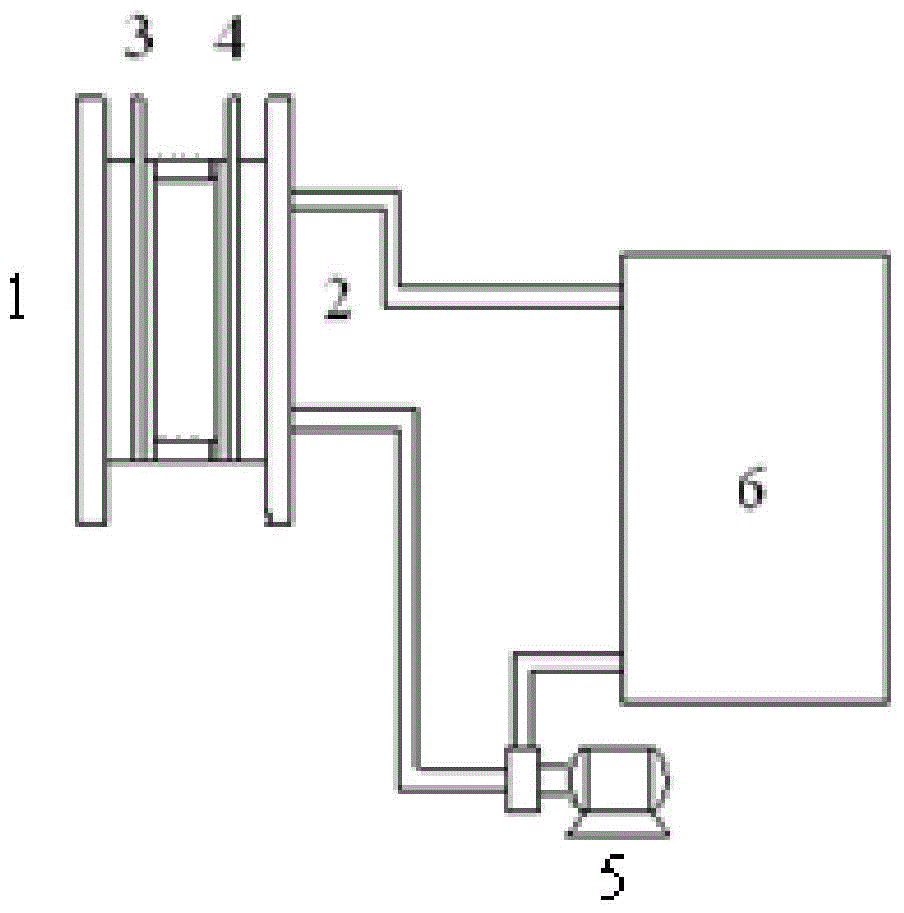

[0025] Positive terminal plate, positive electrode 3x3cm in order of single cell 2 Nickel foam, negative electrode 3x3cm 2 Nickel foam, negative terminal plate. Single battery structure and system see figure 1 .

[0026] Battery test:

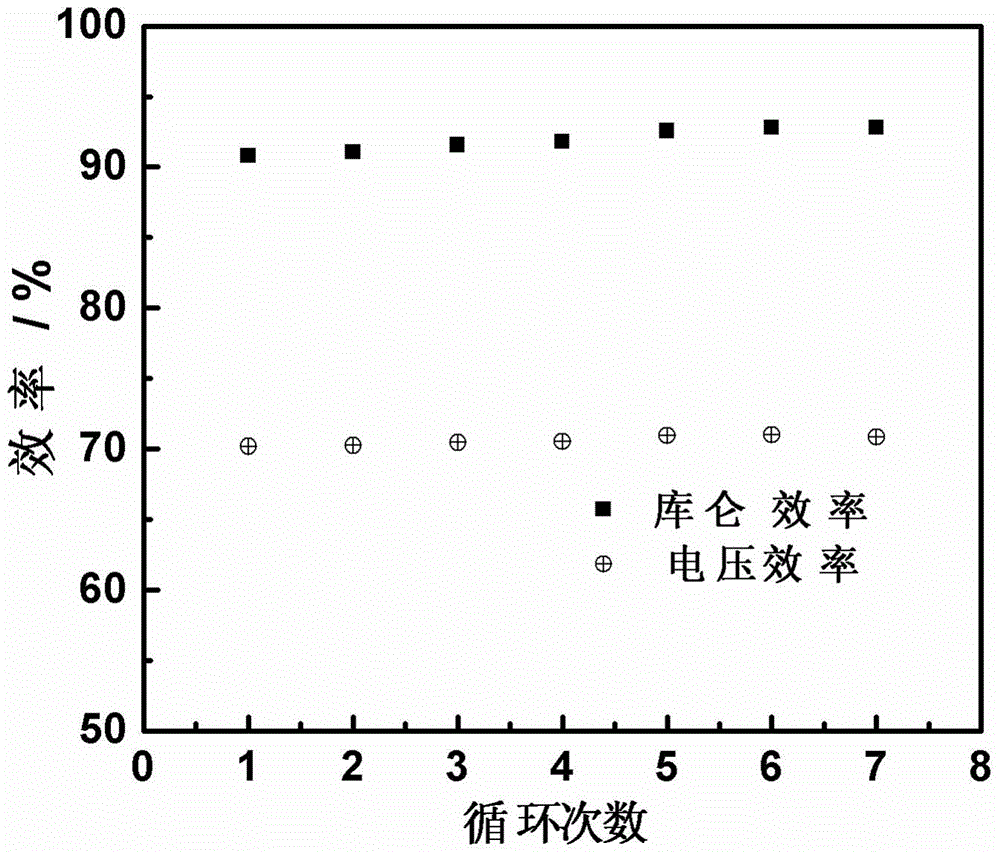

[0027] Electrolyte flow rate: 5ml / min; charge and discharge current density 10mA / cm 2 ; Charging for 1h, the discharge cut-off voltage is 0V. For battery performance see figure 2 , from the charge-discharge current density figure 2 It can be seen that at 10mA / cm 2 ; The charging time is 1h, and the average energy efficiency of the battery reaches about 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com