A control device and method for stamping refrigerator compressor support plate

A refrigerator compressor and control device technology, applied in the direction of presses, feeding devices, positioning devices, etc., can solve the problems of difficult collaboration and high cost, reduce the difficulty of collaboration, save production costs, and meet product quality and stability effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

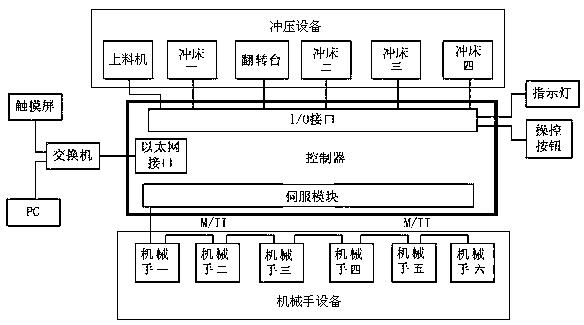

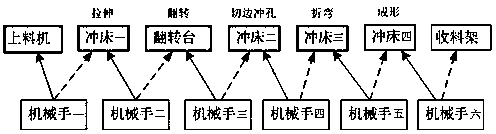

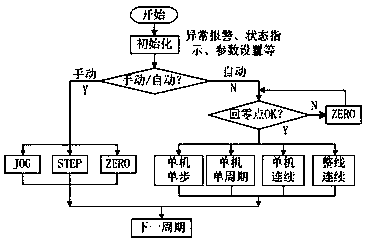

[0029] Such as figure 1 is a structural schematic diagram of the control device of the present invention, figure 2 It is a schematic diagram of the physical position of the control device of the present invention, a control device for stamping the support plate of the refrigerator compressor, including a controller, stamping equipment, manipulator equipment, display module and PC, and the stamping equipment and manipulator equipment are connected separately On both sides of the controller, the controller is the MP2300 controller, which is equipped with a servo module, I / O interface circuit and Ethernet interface circuit. The stamping equipment is arranged in sequence with a feeding machine, a punching machine, a turning table, and a punching machine. 1, Punch 3, Punch 4 and the receiving frame, and the manipulator equipment is arranged in sequence with Manipulator 1, Manipulator 2, Manipulator 3, Manipulator 4, Manipulator 5 and Manipulator 6. The feeding machine, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com