Large-diameter circular ring chain welding machine

A large-diameter, welding machine technology, applied in the mechanical field, can solve problems such as low yield, prone to inductive reactance, and uncompact structure, and achieve the effects of ensuring accuracy, reducing the space occupied by the level, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

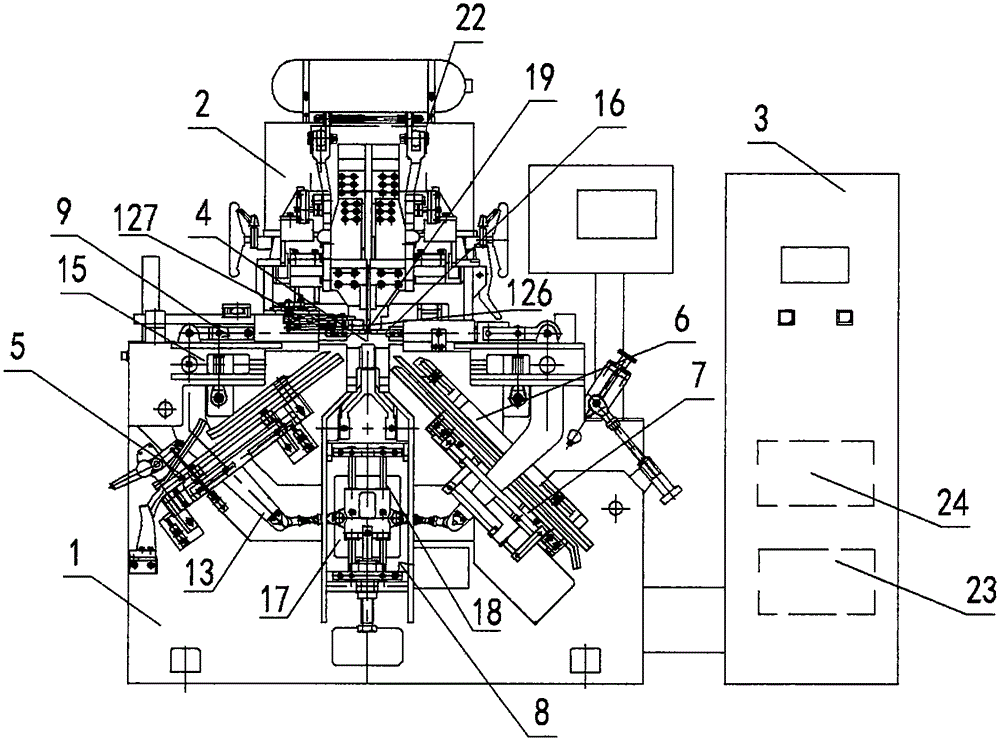

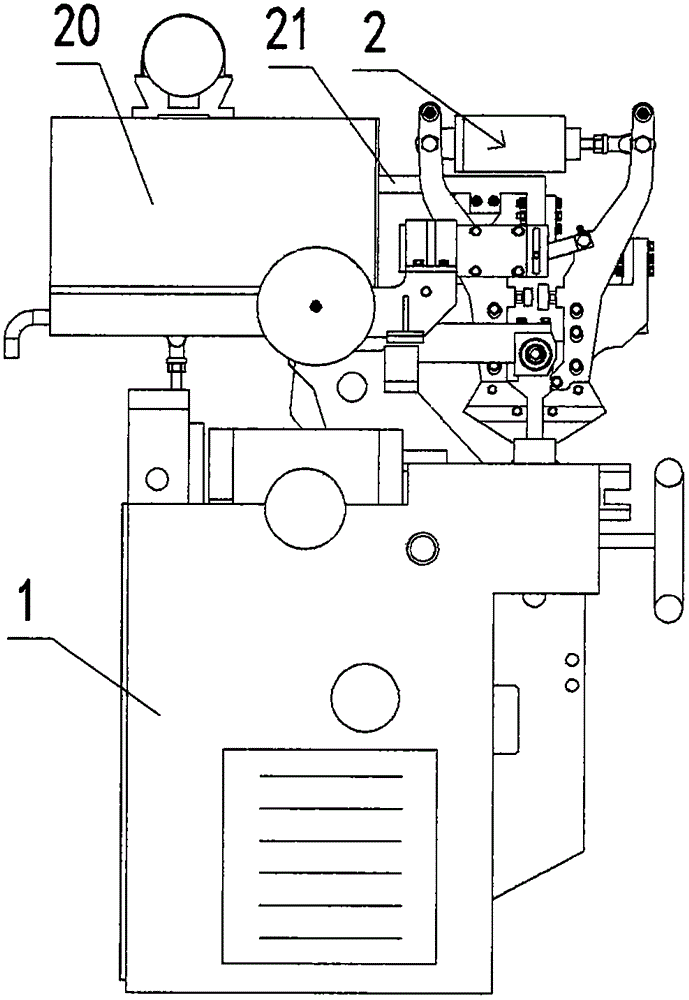

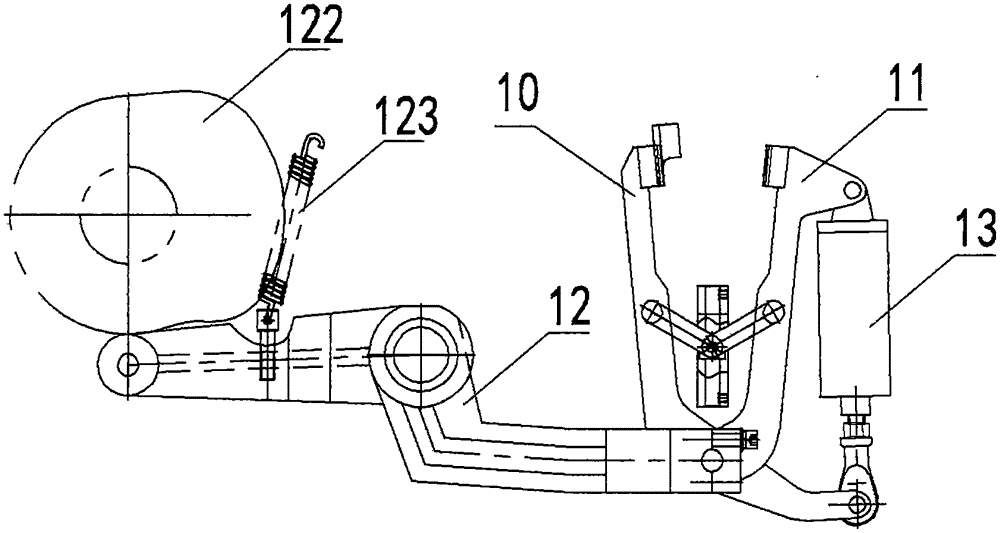

[0022] Such as figure 1 , shown in 2, 3, and 4, the large-diameter circular chain welding machine includes a base 1, and a welding stand 2 is linked by a guide rail above the base, and a welding stand is provided between the welding stand and the base to realize the welding stand up and down. Moving cam set. An electrical control cabinet 3 is provided on one side of the welding platform, a horizontal workbench 4 is provided on the base, and an input track 5 and an output track 6 are respectively arranged on both sides of the horizontal workbench, and the input track and the output track form an included angle of 95°. The included angle can not only reduce the occupied space of the conventional structure, but also enable the workpiece to be in a better processing position when it reaches the horizontal workbench. Through the setting of this angle, it is generally possible to reduce the occupied space by about 20%. The input track and the output track form a 95° equidistant ang...

Embodiment 2

[0025] Such as figure 1, shown in 2, 3, and 4, the large-diameter circular chain welding machine includes a base 1, and a welding stand 2 is linked by a guide rail above the base, and a welding stand is provided between the welding stand and the base to realize the welding stand up and down. Moving cam set. An electrical control cabinet 3 is arranged on one side of the welding platform, a horizontal workbench 4 is arranged on the base, and an input track 5 and an output track 6 are respectively arranged on both sides of the horizontal workbench, and the input track and the output track form an included angle of 99°. The included angle can not only reduce the occupied space of the conventional structure, but also enable the workpiece to be in a better processing position when it reaches the horizontal workbench. Through the setting of this angle, it is generally possible to reduce the occupied space by about 20%. The input track and the output track form a 99° equidistant angl...

Embodiment 3

[0028] Such as figure 1 , shown in 2, 3, and 4, the large-diameter circular chain welding machine includes a base 1, and a welding stand 2 is linked by a guide rail above the base, and a welding stand is provided between the welding stand and the base to realize the welding stand up and down. Moving cam set. An electrical control cabinet 3 is arranged on one side of the welding platform, a horizontal workbench 4 is arranged on the base, and an input track 5 and an output track 6 are respectively arranged on both sides of the horizontal workbench, and the input track and the output track form an included angle of 98°. The included angle can not only reduce the occupied space of the conventional structure, but also enable the workpiece to be in a better processing position when it reaches the horizontal workbench. A mechanical arm 7 capable of pulling the chain to move is provided on the output track, and the mechanical arm mainly plays the role of pulling the chain. The horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com