High-voltage lithium ion battery electrolyte

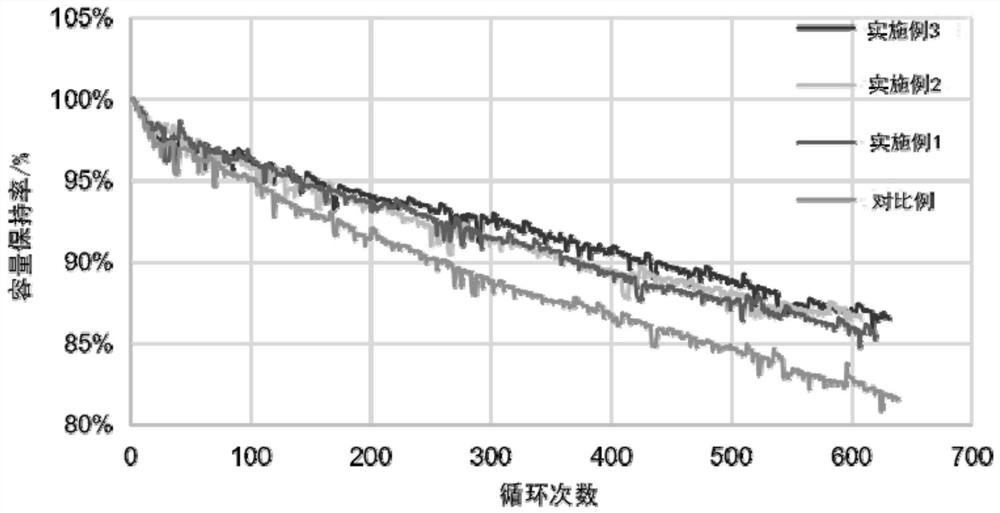

A lithium-ion battery, electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the high temperature and high pressure cycle performance of electrolyte, safety performance needs to be improved, consumption of active materials, battery capacity attenuation, etc. problem, to achieve the effect of improving high temperature and high pressure cycle performance, good compatibility, and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

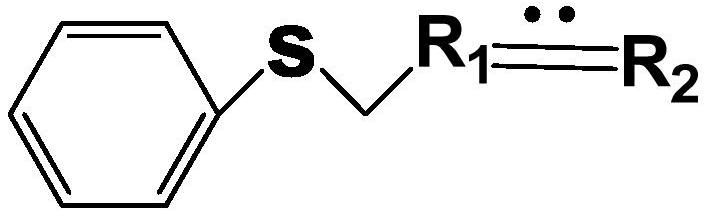

Image

Examples

preparation example Construction

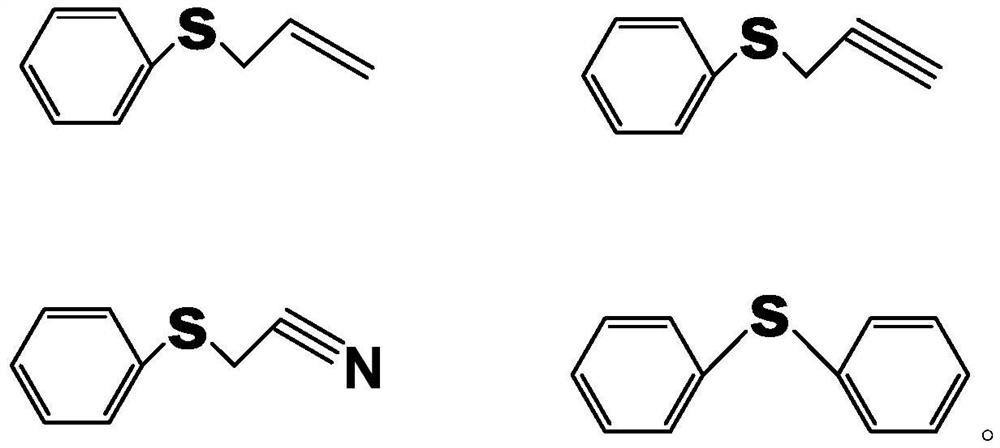

[0034] The preparation method of allyl phenyl sulfide is as follows:

[0035]Put 1.5mmol of palladium catalyst into a three-necked flask, pass inert gas for protection, then add 1.5mmol of disulfide and 1.5mmol of allyl bromide, add 15mL of tetrahydrofuran, heat to 65°C, react for 48h, and the reaction product is diethyl ether Extraction and column purification.

[0036] The main chemical reaction equation is as follows:

[0037]

[0038] The obtained allyl phenyl sulfide was used in the preparation of the electrolyte solution described below.

Embodiment 1

[0040] Keep the moisture in the glove box at about 0.1ppm, and the oxygen content at about 0.1ppm, add dimethyl carbonate (DMC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) to the beaker in sequence at a volume ratio of 1:1:1 During cooling, slowly add lithium hexafluorophosphate when the temperature is not higher than 10°C, adjust the concentration to 1.2mol / L, then add 0.2wt% vinylene carbonate (VC), 5wt% fluoroethylene carbonate (FEC) and 4 wt% of 1,3-propane sultone (PS), and finally 1 wt% of allyl phenyl sulfide was added, and the stirring was continued until the solution became clear, which was carried out under the protection of nitrogen.

Embodiment 2

[0042] Keep the moisture in the glove box at about 0.1ppm, and the oxygen content at about 0.1ppm, add dimethyl carbonate (DMC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) to the beaker in sequence at a volume ratio of 1:1:1 During cooling, slowly add lithium hexafluorophosphate when the temperature is not higher than 10°C, adjust the concentration to 1.2mol / L, then add 0.2wt% vinylene carbonate (VC), 5wt% fluoroethylene carbonate (FEC), 4wt% 1,3-propane sultone (PS), and finally 3wt% allyl phenyl sulfide, and continue stirring until the solution becomes clear. This process is carried out under nitrogen protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com